Anti-skid hydrophobic zebra crossing coating with long-lasting snow melting properties and preparation method of coating

A zebra crossing and snow-melting technology, applied in the field of coatings, can solve the problems of zebra crossing without luminous effect, wet and slippery surface of zebra crossing coating, poor anti-skid performance of zebra crossing, etc., and achieve good bonding and fixing performance, prolong snow melting time, and excellent hydrophobic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

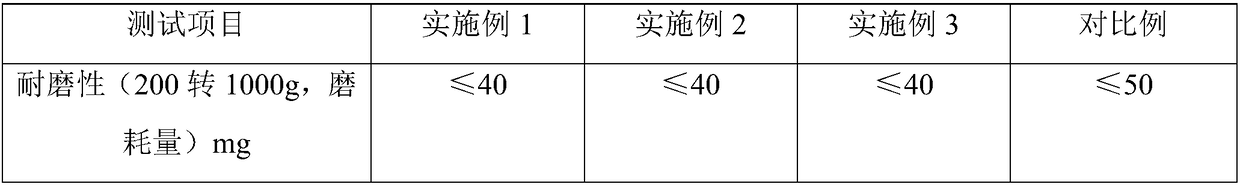

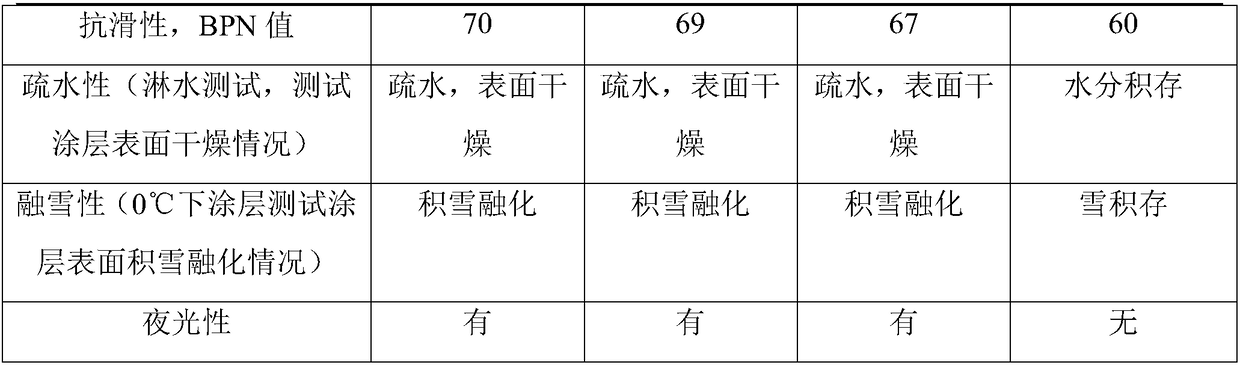

Examples

Embodiment 1

[0016] A non-slip and hydrophobic zebra crossing coating with long-lasting snow-melting properties, including a slurry and a curing agent.

[0017] The components of the slurry and the ratio of parts by mass of each component are: 130 parts of aqueous acrylic emulsion, 25 parts of bisphenol A epoxy resin, 6 parts of 2-ethylhexyl sodium sulfate, 24 parts of titanium dioxide, 3 parts of dispersant, 2.5 parts of water-based wetting agent, 2.5 parts of leveling agent, 6 parts of modified nano-silica powder, 6 parts of melting ice and snow powder, 4 parts of luminous powder, 6 parts of quartz sand, 30 parts of water;

[0018] The components of the curing agent and the ratio of parts by mass of each component are: 100 parts of silicone-modified acrylic resin, 25 parts of ethyl α-cyanoacrylate, and 35 parts of triethylenetetramine.

[0019] The molecular weight of the aqueous acrylic emulsion is 300,000, and the acid value is 50 mgKOH / g.

[0020] The synthesis method of the modified...

Embodiment 2

[0037] A non-slip and hydrophobic zebra crossing coating with long-lasting snow-melting properties, including a slurry and a curing agent.

[0038] The components of the slurry and the ratio of parts by mass of each component are: 120 parts of aqueous acrylic emulsion, 30 parts of bisphenol A epoxy resin, 8 parts of 2-ethylhexyl sodium sulfate, 25 parts of titanium dioxide, 5 parts of dispersant, 3 parts of water-based wetting agent, 3 parts of leveling agent, 5 parts of modified nano-silica powder, 8 parts of melting ice and snow powder, 5 parts of luminous powder, 5 parts of quartz sand, 40 parts of water;

[0039]The components of the curing agent and the ratio of parts by mass of each component are: 100 parts of silicone-modified acrylic resin, 20 parts of ethyl α-cyanoacrylate, and 40 parts of triethylenetetramine.

[0040] The molecular weight of the aqueous acrylic emulsion is 300,000, and the acid value is 55 mgKOH / g.

[0041] The synthesis method of the modified nano...

Embodiment 3

[0048] A non-slip and hydrophobic zebra crossing coating with long-lasting snow-melting properties, including a slurry and a curing agent.

[0049] The components of the slurry and the ratio of parts by mass of each component are: 150 parts of aqueous acrylic emulsion, 20 parts of bisphenol A epoxy resin, 5 parts of 2-ethylhexyl sodium sulfate, 20 parts of titanium dioxide, 5 parts of dispersant, 2 parts of water-based wetting agent, 2 parts of leveling agent, 8 parts of modified nano-silica powder, 8 parts of melting ice and snow powder, 3 parts of luminous powder, 8 parts of quartz sand, 20 parts of water;

[0050] The components of the curing agent and the ratio of parts by mass of each component are: 100 parts of silicone-modified acrylic resin, 30 parts of ethyl α-cyanoacrylate, and 30 parts of triethylenetetramine.

[0051] The molecular weight of the aqueous acrylic emulsion is 300,000, and the acid value is 52 mgKOH / g.

[0052] The synthesis method of the modified nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com