Archimedes spiral filtering device

An Archimedes screw and filter device technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing air flow, reducing separation effect, and increasing the operating load of fans, and achieves high filtration efficiency. , good effect, the effect of reducing oil mist and impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

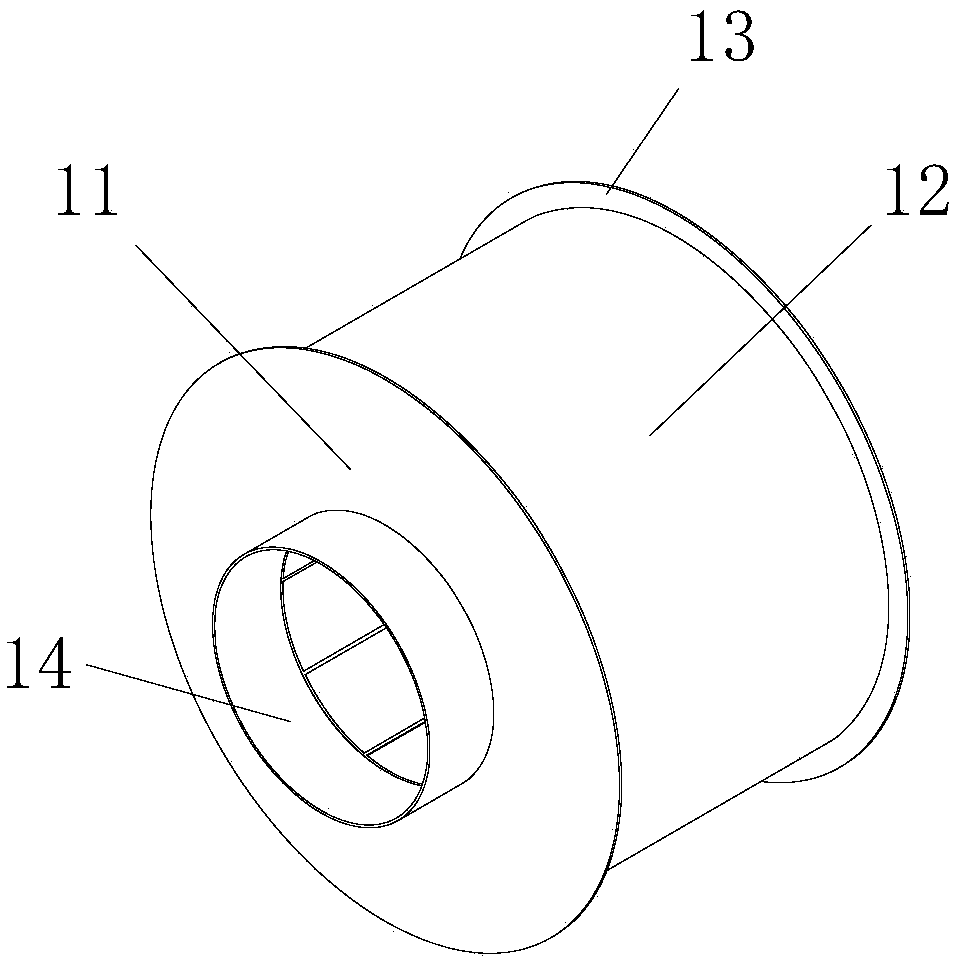

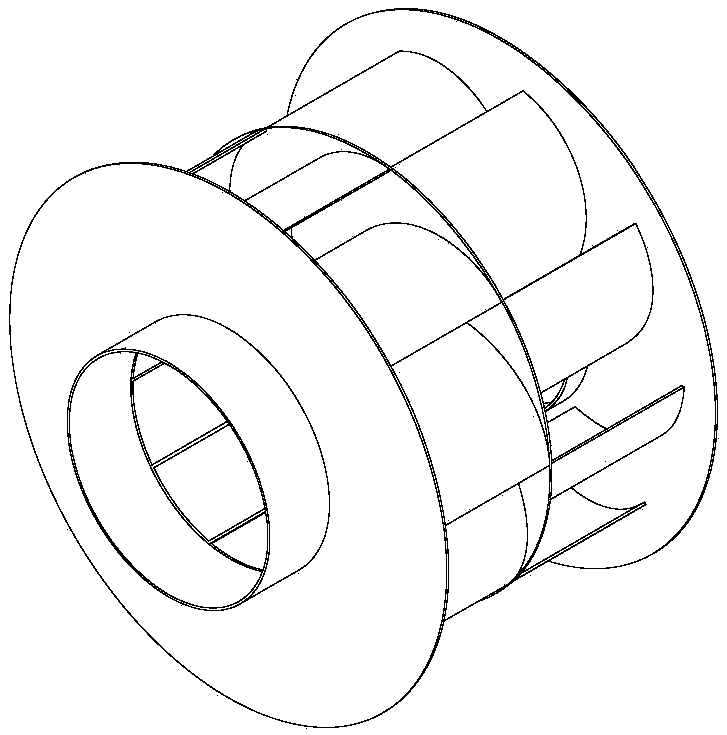

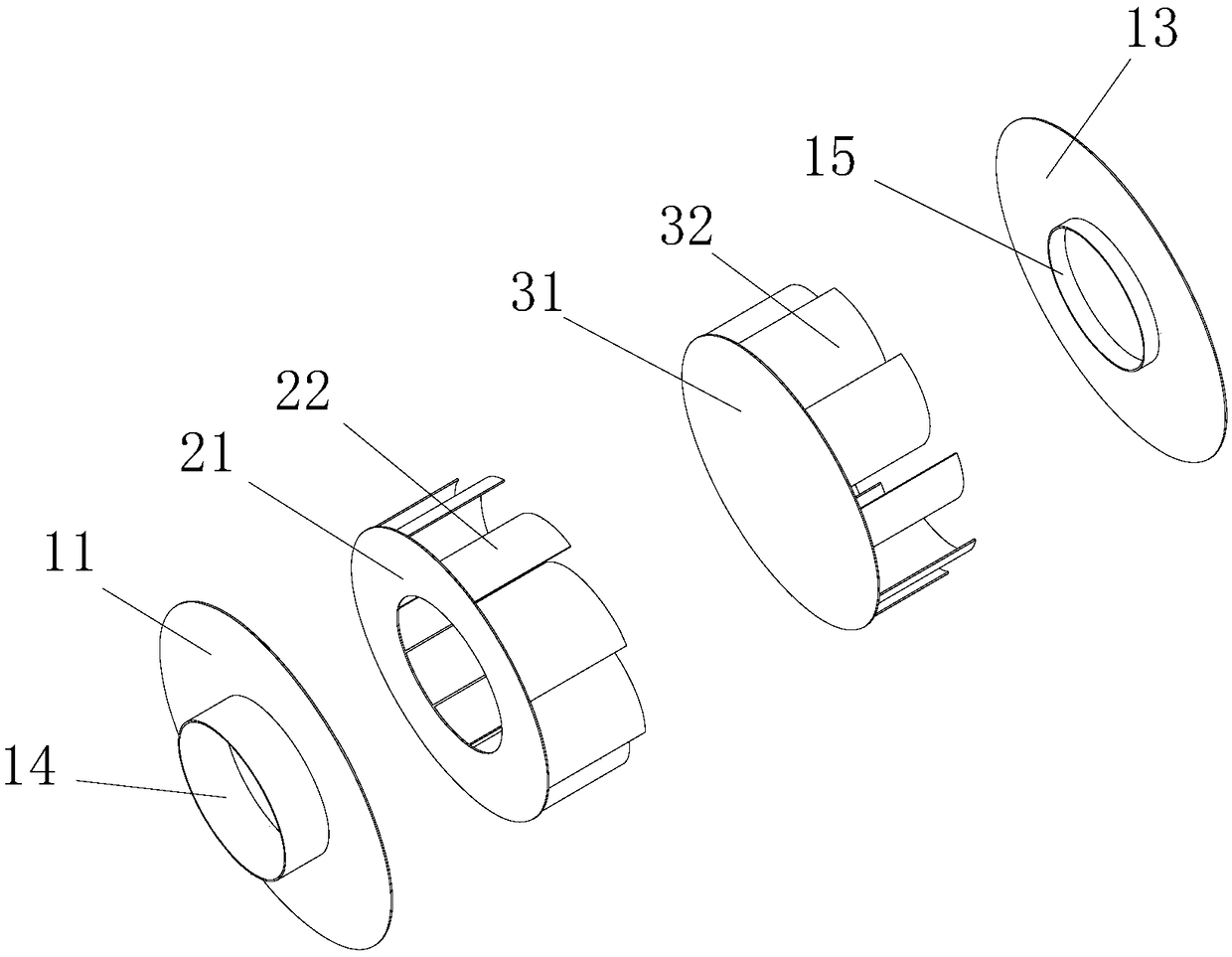

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention discloses an Archimedes spiral filter device, which is installed in the oil mist collector as the first layer of filter device, and utilizes the Archimedes spiral principle to absorb most of the oil mist in the air and Collect them to reduce the content of oil mist and impurities in the air. The filter device mainly includes a shell, a first filter module that guides air from the middle into the periphery and outflow, and a second filter module from the periphery into the middle and outflow. Both the first filter module and the second filter module are installed in the casing, and the first filter module is located before the second filter module. When working, the air with oil mist and impurities enters the filter device from the air inlet of the shell, enters from the middle of the first filter module, flows out around it, enters from the surroundings of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com