High-power power electronic device applied to MMC and operation method thereof

A technology of power electronic devices and operation methods, which is applied in the field of electric power, can solve problems such as high reverse recovery current, increased volume, and large on-state loss, and achieve the effects of reducing turn-off loss, reducing overall cost, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be further described in conjunction with the technical solutions of the present invention and the accompanying drawings.

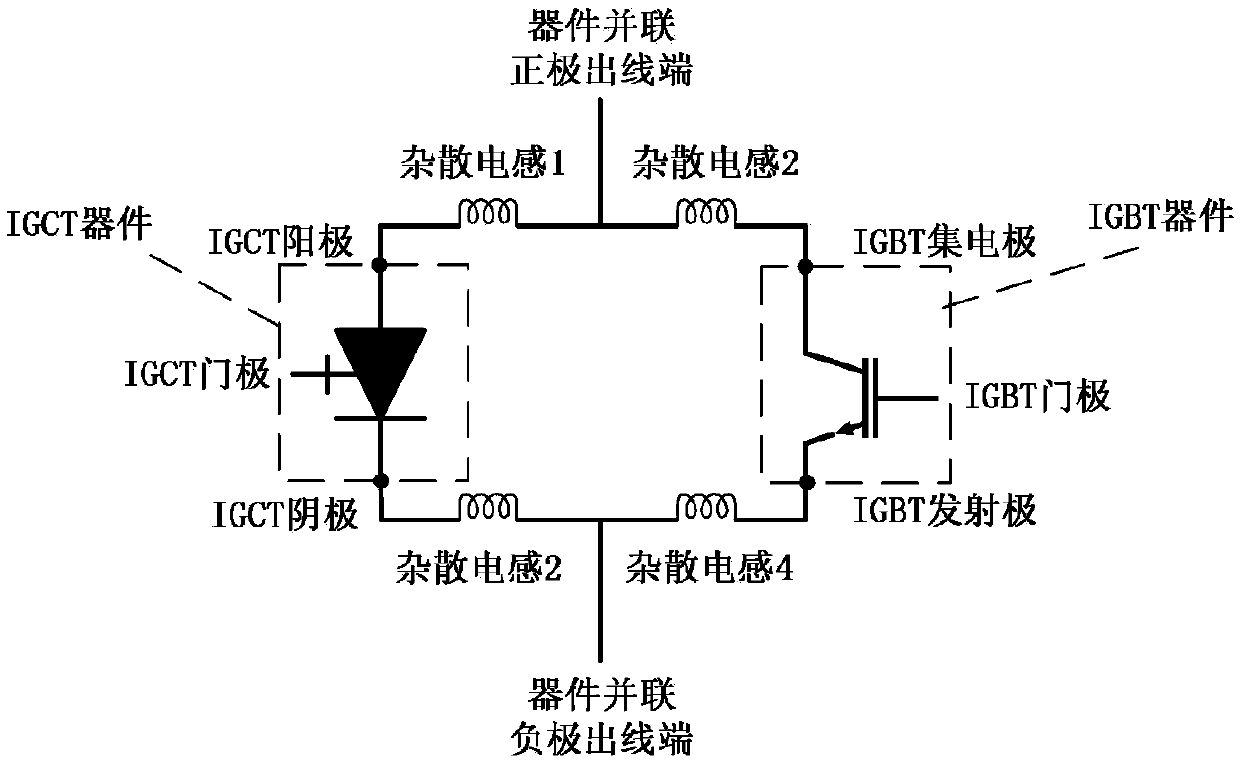

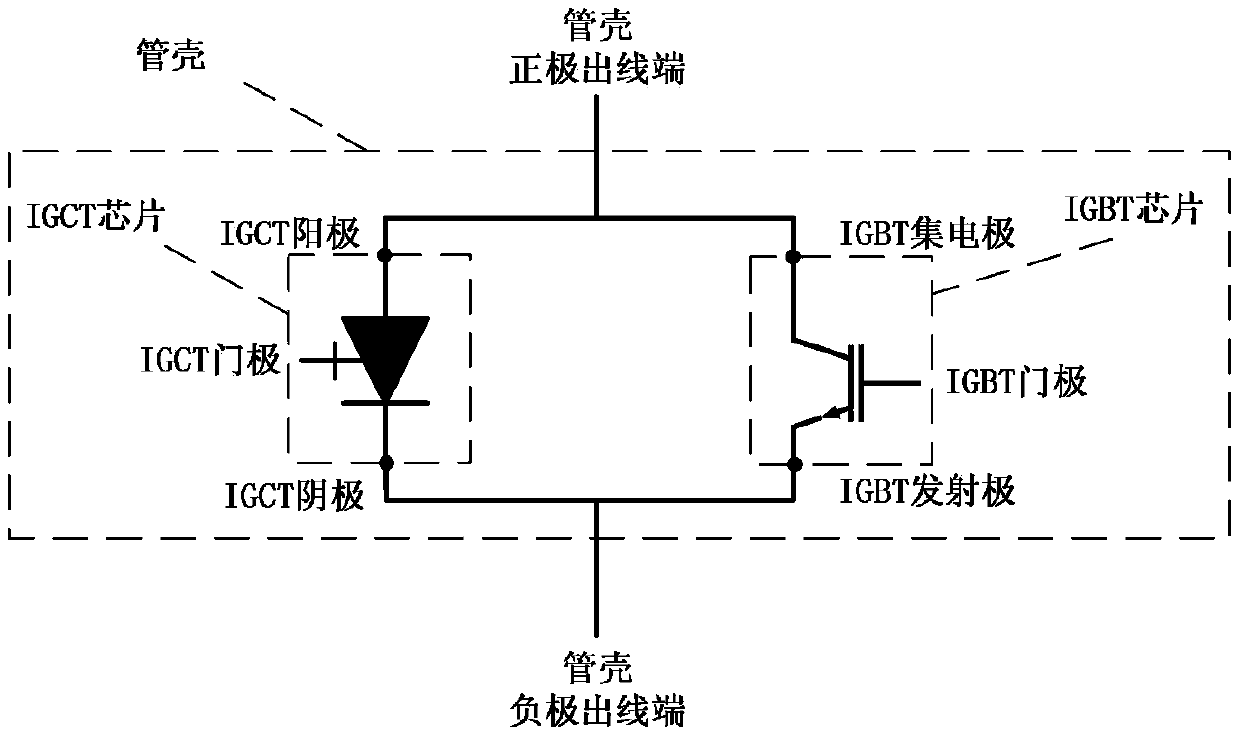

[0042] The high power electronic device applied to MMC of the present invention, such as figure 1 Shown, including an insulated gate bipolar transistor IGBT device and an integrated gate commutated thyristor IGCT device. The IGBT device is connected in parallel with the IGCT device, and the voltage level of the IGBT device and the IGCT device are the same, and the current level is proportional. Among them, the collector of the IGBT device is connected in parallel with the anode of the IGCT device to lead to the positive terminal; the emitter of the IGBT device is connected in parallel to the cathode of the IGCT device to lead to the negative terminal; figure 1 As shown, this kind of power electronic device generates stray inductance 1-4 at the collector and emitter of the IGBT device and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com