Cladding tube internal pressure bursting test device and method

A blasting test and cladding tube technology, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of low heating furnace heating temperature, failure to meet the test parameter requirements of accident-tolerant fuel cladding tubes, and inability to achieve internal pressure blasting. , to achieve the effect of controllable boost speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

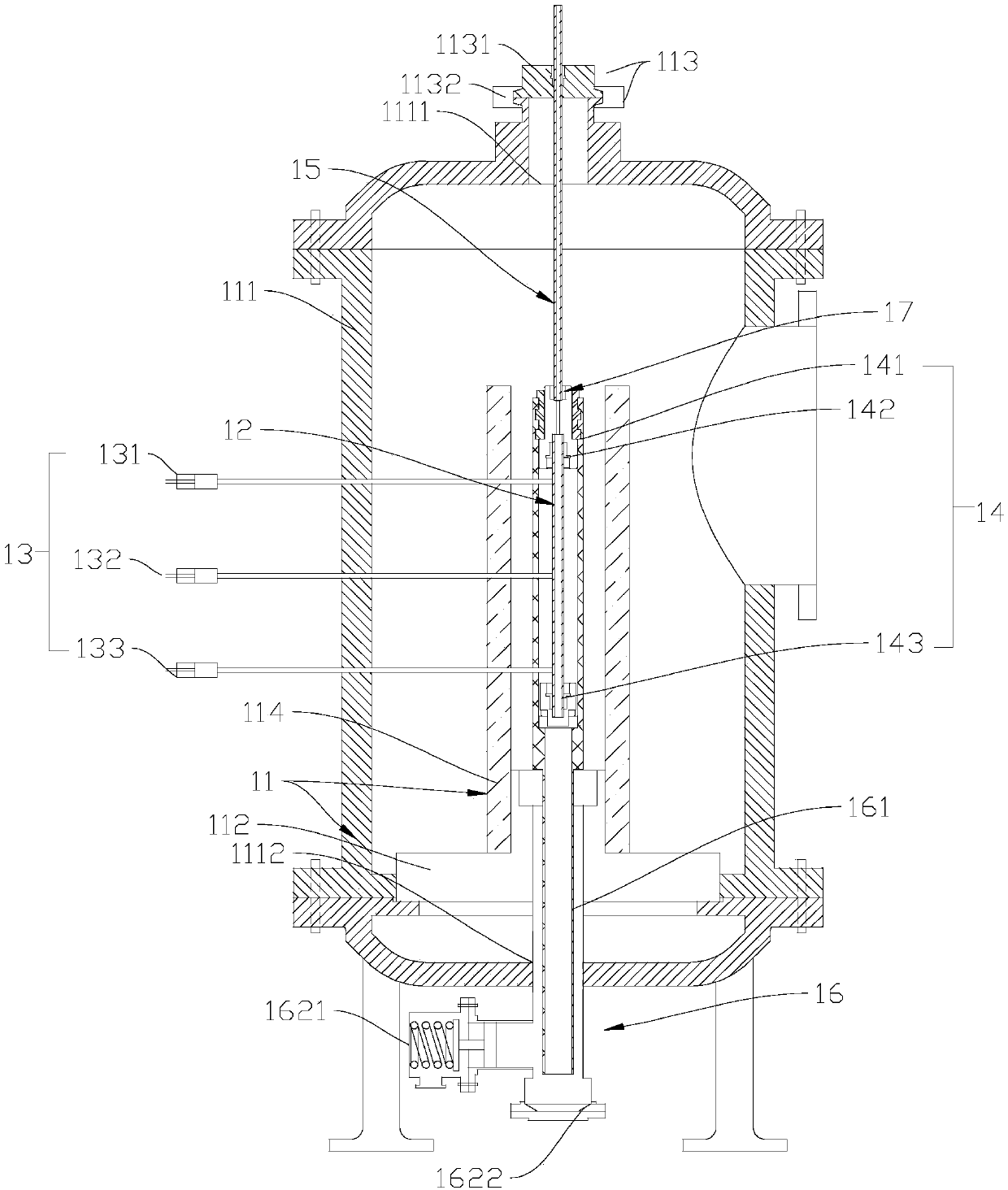

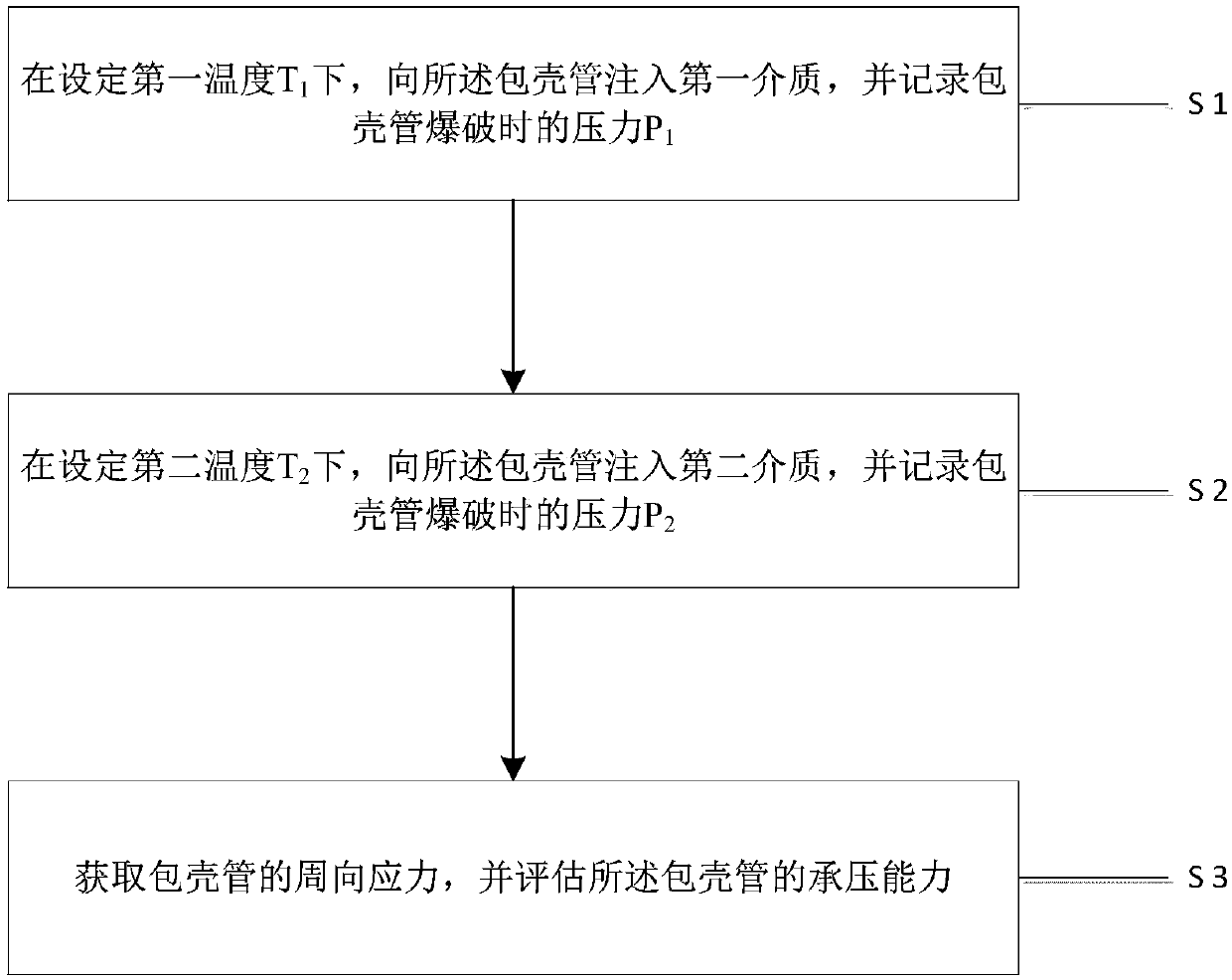

[0058] figure 1 A preferred embodiment of the cladding tube internal pressure burst test device of the present invention is shown,

[0059] The cladding tube internal pressure blasting test device is a kind of internal pressure blasting test device that can realize high temperature, high vacuum, and controllable boosting speed. The pressure bearing capacity in the environment provides an important data reference for the safety performance evaluation of the fault-tolerant cladding tube under accident conditions.

[0060] The cladding tube internal pressure burst test device includes a first medium source, a second medium source, a vacuum heating device 11, a cladding tube 12 arranged in the vacuum heating device 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com