Pulley device and rotary drilling rig and long spiral drilling machine using pulley device

A pulley and wheel hub technology is applied in the field of pulley devices to facilitate maintenance, improve connection reliability, and simplify replacement steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0039] Embodiment of the pulley device: the pulley device belongs to the heavy-duty pulley and is mainly used in engineering machinery and related mechanisms.

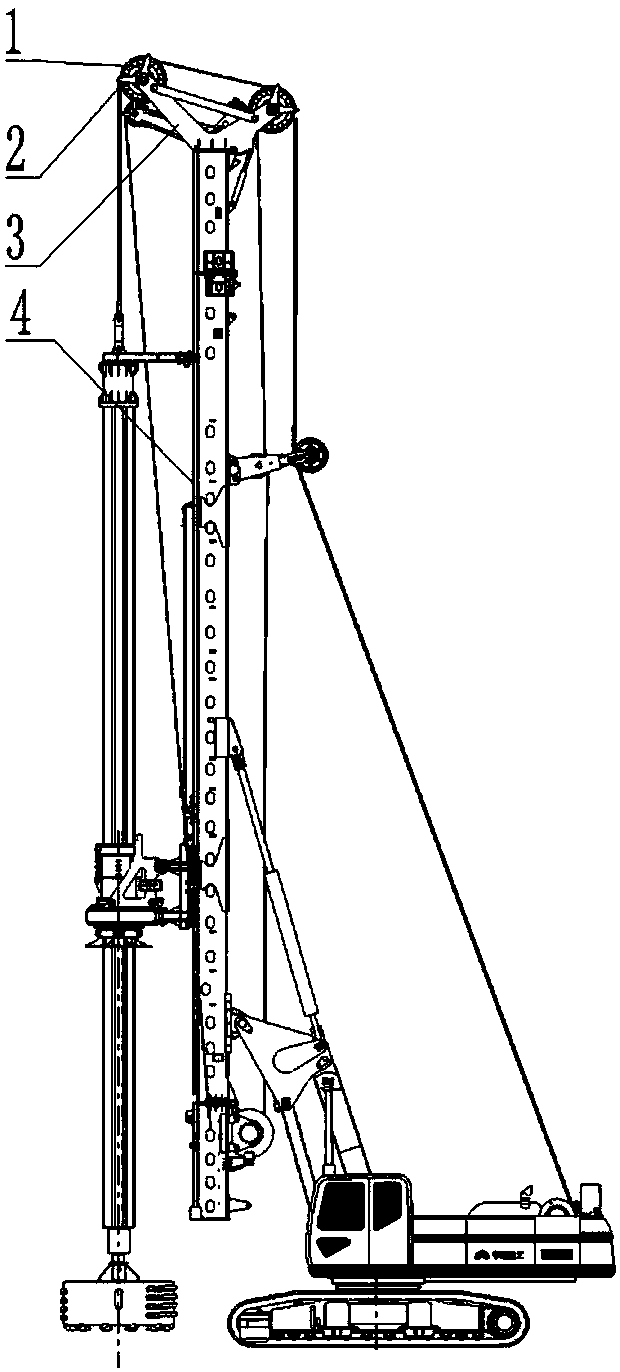

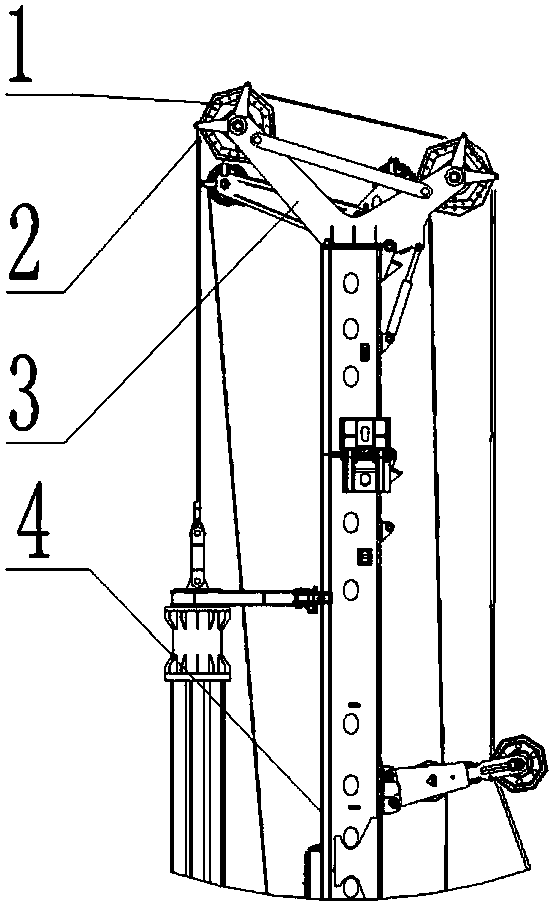

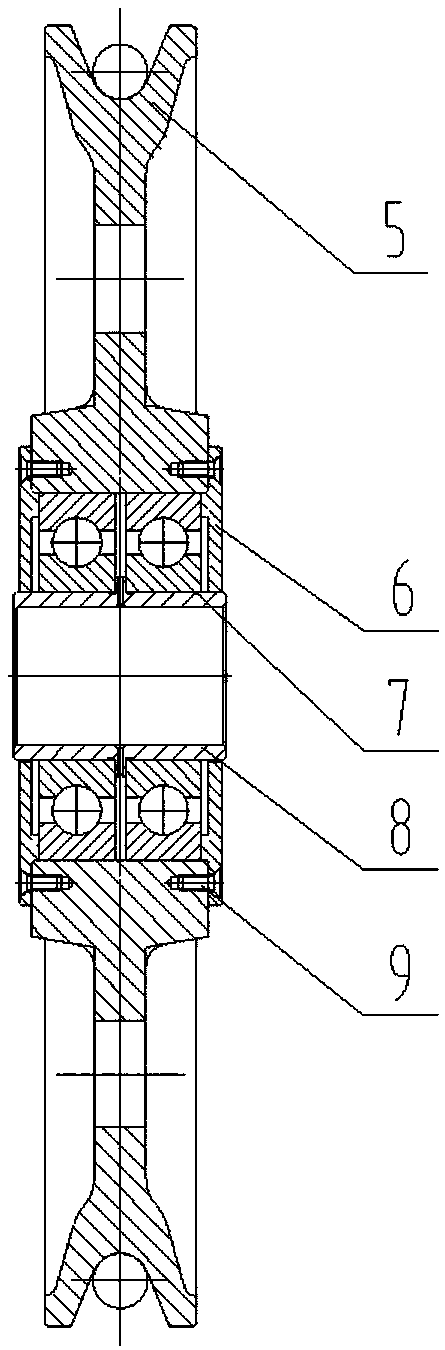

[0040] Such as Figure 1 to Figure 4 As shown, the pulley device is mainly composed of structural components, functional components and connecting components.

[0041] The structural components include: a shaft sleeve 101 , a bearing 102 , a hub 103 and a rim 104 .

[0042] The shaft sleeve 101 is a circular sleeve, and the center of the shaft sleeve 101 is provided with a flange protruding from the outer peripheral surface.

[0043]Bearing 102 has two, and two bearings 102 all adopt deep groove ball bearing 102. Of course, since the deep g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com