Blue light-proof protective film

A technology of anti-blue light and protective film, applied in the direction of film/sheet adhesive, ion implantation plating, coating, etc., can solve the problem of poor anti-blue light effect, etc., and achieve the effect of good anti-ultraviolet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

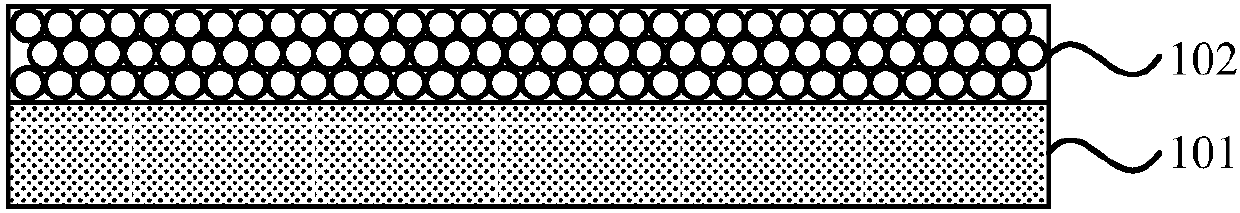

[0050] An anti-blue light protective film such as figure 1 As shown, it includes a transparent substrate 101 and an anti-blue light layer 102 disposed on one side of the transparent substrate 101;

[0051] The transparent substrate 101 is a PET film with a thickness of 200 μm; the anti-blue light layer 102 is composed of nano-sized tungsten oxide particles with a particle size of 25-150 nm and a thickness of 100 nm.

[0052] The anti-blue light layer 102 is plated on the surface of the transparent substrate 101 by magnetron sputtering.

Embodiment 2

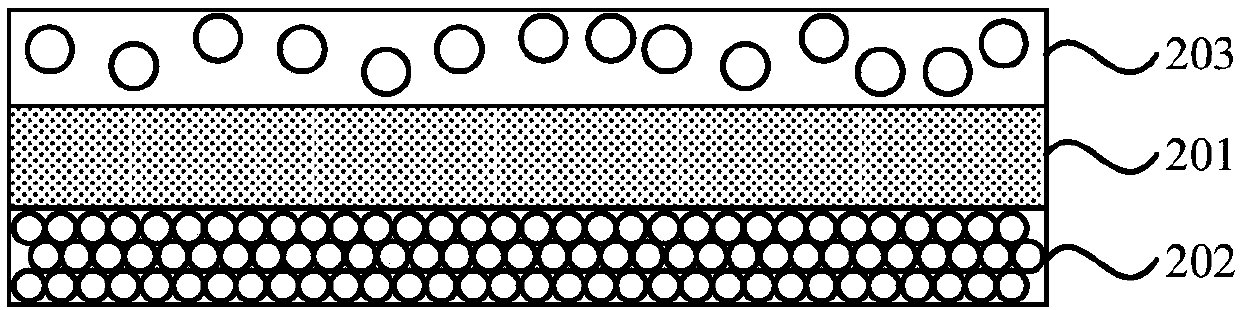

[0054] An anti-blue light protective film such as figure 2 As shown, it includes a transparent substrate 201, an anti-blue light layer 202 disposed on one side of the transparent substrate 201, and an anti-glare layer 203 disposed on the other side of the transparent substrate 201;

[0055] The transparent substrate 201 is a PC film containing an ultraviolet absorber, with a thickness of 150 μm; the anti-blue light layer 202 is composed of nano-titanium dioxide particles with a particle size of 25-150 nm, and the thickness is 200 nm; the anti-glare layer 203 is composed of organic silicon particles with a particle size of 50 nm-10 μm It is composed of polyurethane acrylate in a mass ratio of 1:5, and the thickness is 20 μm.

[0056] The anti-blue light layer 202 is plated on the surface of the transparent substrate 201 by magnetron sputtering.

Embodiment 3

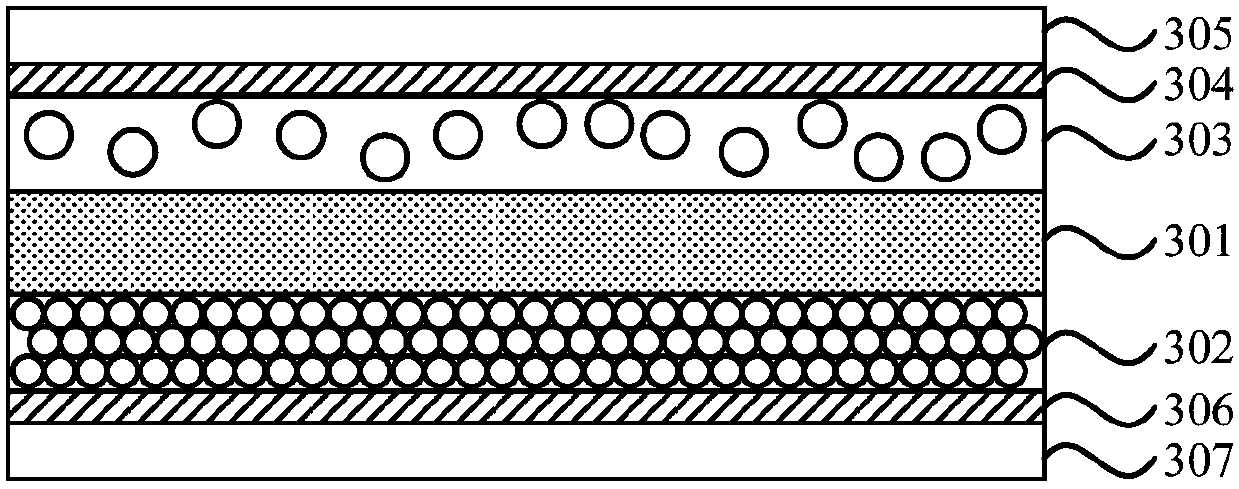

[0058] An anti-blue light protective film such as image 3 As shown, from top to bottom, it includes a protective layer 305, a first adhesive layer 304, an anti-glare layer 303, a transparent substrate 301, an anti-blue light layer 302, a second adhesive layer 306 and a release film 307;

[0059] Among them, the transparent substrate 301 is a TAC film containing an ultraviolet absorber, with a thickness of 50 μm; the anti-blue light layer 302 is composed of nano-silica particles with a particle size of 25-150 nm, and a thickness of 500 nm; the anti-glare layer 303 is made of 50 nm-10 μm Acrylic particles and polyester acrylate are composed at a mass ratio of 1:15, and the thickness is 15 μm; the first adhesive layer 304 and the second adhesive layer 306 are formed by acrylic adhesive; the protective layer 305 is a PET film, and the thickness is 5 μm .

[0060] The anti-blue light layer 302 is plated on the surface of the transparent substrate 301 by magnetron sputtering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com