Preparation method of high-intensity heat-proof long glass fiber/nylon 6/nylon 66 composite material

A composite material and long glass fiber technology, applied in the field of preparation of a high-strength and heat-resistant long glass fiber/nylon 6/nylon 66 composite material, can solve the problems of low dimensional stability, poor thermal stability, limited nylon, etc. Improve mechanical properties, improve heat resistance, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

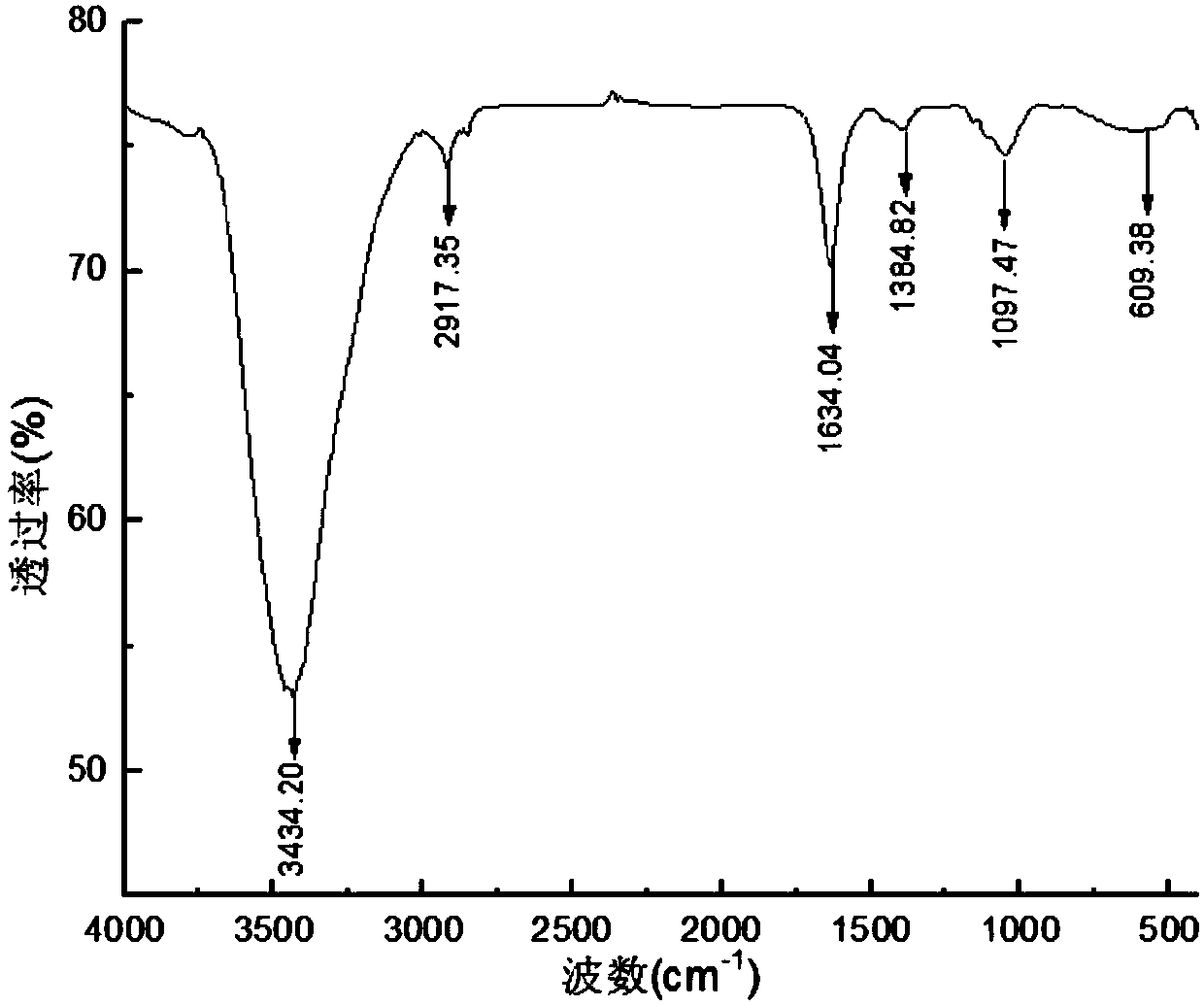

Image

Examples

Embodiment 1

[0033] A preparation method of high-strength heat-resistant long glass fiber / nylon 6 / nylon 66 composite material, comprising the following steps:

[0034] a. Raw material pretreatment, batching and mixing:

[0035] Take raw materials nylon 6 (abbreviated as PA6) and nylon 66 (abbreviated as PA66), dry at 95°C for 8 hours; take alkali-free long glass fiber (abbreviated as LGF);

[0036] Take 50 parts by weight of nylon 6 (abbreviated as PA6) after drying, 18.7 parts by weight of nylon 66 (abbreviated as PA66), 1.0 parts by weight of PP-g-MAH, and 0.3 parts by weight of high temperature resistant thermal oxygen stabilizer, and mix them uniformly to obtain a mixture Get the long glass fiber (being called for short LGF, long glass fiber) of 30 weight parts, standby;

[0037] b. The mixture is melted, extruded, and dried: pour the mixture into a high-speed (preferably 100r / min) mixer, (high-speed) stir and mix for 5 minutes, so that nylon 6 and nylon 66 are evenly dispersed in oth...

Embodiment 2

[0044] A preparation method of high-strength heat-resistant long glass fiber / nylon 6 / nylon 66 composite material, comprising the following steps:

[0045] a. Raw material pretreatment, batching and mixing:

[0046] Take raw materials nylon 6 (abbreviated as PA6) and nylon 66 (abbreviated as PA66), dry at 95°C for 8 hours; take alkali-free long glass fiber (abbreviated as LGF);

[0047] Get dried raw material nylon-6 (abbreviated as PA6) 44 parts by weight, nylon-66 (abbreviated as PA66) 14.1 parts by weight, PP-g-MAH 1.5 parts by weight, HQW thermal oxygen stabilizer 0.4 parts by weight, mix uniformly, get mixed Material; Get the long glass fiber of 40 weight parts, standby;

[0048] b. The mixture is melted, extruded, and dried: pour the mixture into a high-speed (preferably 100r / min) mixer, (high-speed) stir and mix for 5 minutes, so that nylon 6 and nylon 66 are evenly dispersed in other In the raw materials, the mixture is added to the feeding funnel of the twin-screw ex...

Embodiment 3

[0055] A preparation method of high-strength heat-resistant long glass fiber / nylon 6 / nylon 66 composite material, comprising the following steps:

[0056] a. Raw material pretreatment, batching and mixing:

[0057] Take raw materials nylon 6 (abbreviated as PA6) and nylon 66 (abbreviated as PA66), dry at 95°C for 8 hours; take alkali-free long glass fiber (abbreviated as LGF);

[0058] Get dried raw material nylon-6 (abbreviated as PA6) 47 parts by weight, nylon-66 (abbreviated as PA66) 14 parts by weight, 3.0 parts by weight of PP-g-MAH, 0.4 parts by weight of HQW thermal oxygen stabilizer, anhydrous calcium chloride 0.6 parts by weight, uniformly mixed, to obtain a compound; get 35 parts by weight of long glass fiber, for subsequent use;

[0059] b. The mixture is melted, extruded, and dried: pour the mixture into a high-speed (preferably 100r / min) mixer, (high-speed) stir and mix for 5 minutes, so that nylon 6 and nylon 66 are evenly dispersed in other In the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com