A concrete slump retaining agent

A slump-retaining agent and concrete technology, applied in the field of concrete slump-retaining agent, can solve the problems of affecting the setting time of cement, difficult to control the amount of water reducing agent, affecting the quality of the project, etc., so as to improve the slump retention capacity and the coating capacity. , The slump protection effect is obvious, and the effect of reducing the loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

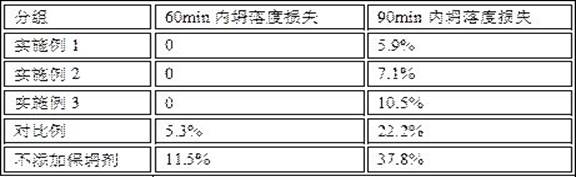

Examples

Embodiment 1

[0014] A concrete slump-retaining agent is prepared from the following raw materials in parts by weight: 13 parts of polyglutamic acid / oligochitosan hydrogel, 8 parts of maleic anhydride, 6 parts of polyethylene oxide, ethylenediaminetetramethylenephosphine 7 parts of sodium bicarbonate, 5 parts of hydroxyethylamine, 4 parts of diethanol monoisopropanolamine, 8 parts of ethylenediamine, and 45 parts of water.

[0015] The polyglutamic acid / chitooligosaccharide hydrogel is prepared by the following method: adding polyglutamic acid, hyaluronic acid and chitooligosaccharide to water, heating to 85°C to dissolve, cooling to 30°C, Add N-hydroxysuccinimide to cross-link for 40 minutes to obtain polyglutamic acid / chitooligosaccharide hydrogel.

[0016] Said, the weight ratio of polyglutamic acid, hyaluronic acid, chitosan oligosaccharide and water is 5.5:4.5:5.5:100.

[0017] As mentioned, the weight ratio of N-hydroxysuccinimide to water is 3:100.

Embodiment 2

[0019] A concrete slump-retaining agent is prepared from the following raw materials in parts by weight: 10 parts of polyglutamic acid / oligochitosan hydrogel, 5 parts of maleic anhydride, 8 parts of polyethylene oxide, ethylenediaminetetramethylenephosphine 8 parts of sodium bicarbonate, 3 parts of hydroxyethylamine, 5 parts of diethanol monoisopropanolamine, 10 parts of ethylenediamine, and 40 parts of water.

[0020] The polyglutamic acid / chitooligosaccharide hydrogel is prepared by the following method: adding polyglutamic acid, hyaluronic acid and chitooligosaccharide to water, heating to 80°C to dissolve, cooling to 32°C, Add N-hydroxysuccinimide to cross-link for 50 minutes to obtain polyglutamic acid / chitooligosaccharide hydrogel.

[0021] Said, the weight ratio of polyglutamic acid, hyaluronic acid, chitosan oligosaccharide and water is 5:5:5:100.

[0022] As mentioned, the weight ratio of N-hydroxysuccinimide to water is 3.5:100.

Embodiment 3

[0024] A concrete slump-retaining agent is prepared from the following raw materials in parts by weight: 15 parts of polyglutamic acid / oligochitosan hydrogel, 10 parts of maleic anhydride, 4 parts of polyethylene oxide, ethylenediaminetetramethylenephosphine 6 parts of sodium bicarbonate, 8 parts of hydroxyethylamine, 3 parts of diethanol monoisopropanolamine, 6 parts of ethylenediamine, and 50 parts of water.

[0025] As described, the polyglutamic acid / oligochitosan hydrogel is prepared by the following method: adding polyglutamic acid, hyaluronic acid and oligochitosan to water, heating to 90°C to dissolve, cooling to 28°C, Add N-hydroxysuccinimide to cross-link for 30 minutes to obtain polyglutamic acid / chitooligosaccharide hydrogel.

[0026] Said, the weight ratio of polyglutamic acid, hyaluronic acid, chitosan oligosaccharide and water is 6:4:6:100.

[0027] As mentioned, the weight ratio of N-hydroxysuccinimide to water is 2.5:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com