Normal temperature water reducing agent with high water reducing rate and excellent dispersibility and preparation method thereof

A water-reducing agent and dispersibility technology, which is applied in the field of normal-temperature water-reducing agent and its preparation, can solve the problems of excessive concrete slump loss, difficulty in realizing the effect of water-reducing agent, and difficulty in controlling the heating temperature, and reduce shrinkage. The effect of cracking rate, increasing water-reducing function and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

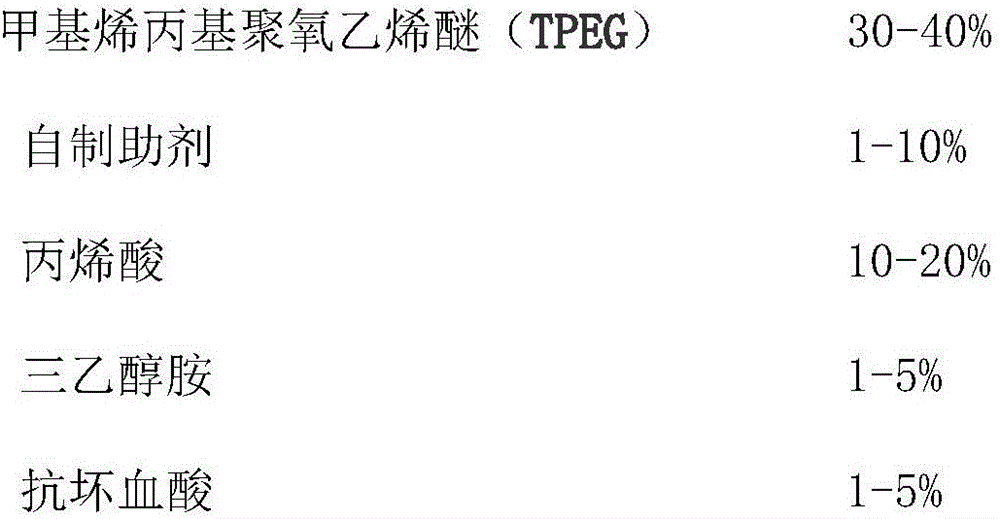

[0026] Raw material ratio:

[0027] Methallyl polyoxyethylene ether (TPEG) 30%, self-made additives 5%, acrylic acid 10%, triethanolamine 3%, ascorbic acid 3%, caustic soda 4%, water 45%.

[0028] Homemade Auxiliaries: Acrylic acid: 10%, Ammonium persulfate: 10%, Water: 80%.

[0029] The preparation steps include: put half of the formula ratio of water, methallyl polyoxyethylene ether and self-made additives in a reaction vessel without stirring, add acrylic acid, triethanolamine, ascorbic acid after standing for 3 hours, and the other half of the formula ratio of water , The addition process of the above materials needs to be completed within 30 minutes; after stirring the obtained mixture for 2 hours, add caustic soda, and stir evenly to obtain a room temperature water reducer with high water reducing rate and excellent dispersibility.

Embodiment 2

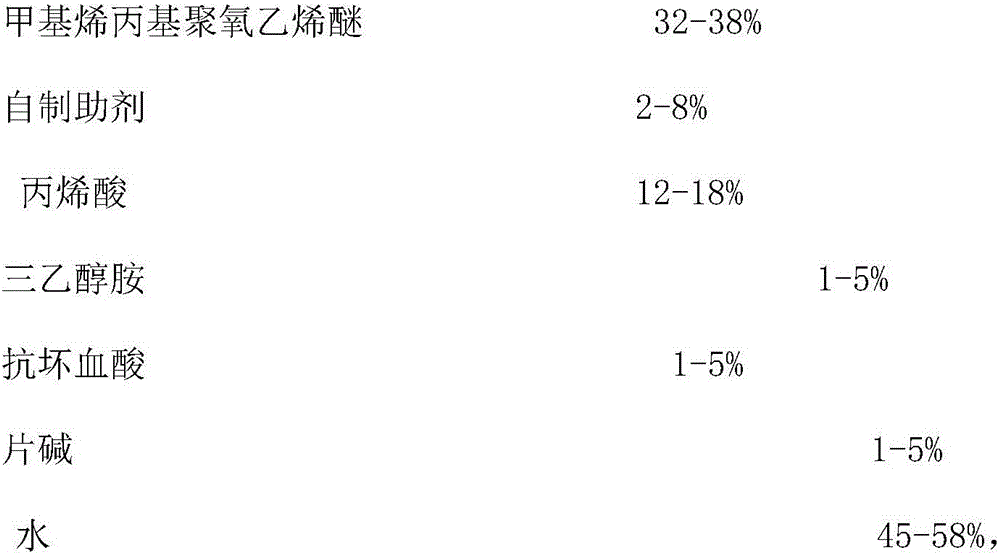

[0031] Raw material ratio:

[0032] Methallyl polyoxyethylene ether (TPEG) 35%, self-made additives 2%, acrylic acid 12%, triethanolamine 2%, ascorbic acid 2%, caustic soda 2%, water 45%.

[0033] Homemade additives: acrylic acid 15%, ammonium persulfate: 8%, water 77%.

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0036] Methallyl polyoxyethylene ether (TPEG) 40%, self-made additives 1%, acrylic acid 15%, triethanolamine 2%, ascorbic acid 1%, caustic soda 1%, water 40%.

[0037] Homemade additives: acrylic acid 20%, ammonium persulfate: 10%, water 70%.

[0038] The preparation method is the same as in Example 1.

[0039] Performance testing of the prepared water reducer

[0040] Concrete slump retention capacity

[0041] Taking c30 concrete as an example, the mix ratio is shown in Table 1:

[0042] Table 1

[0043]

[0044] The dispersibility and slump retention ability are shown in Table 2:

[0045] Table 2

[0046]

[0047] Samples 1-3 are water reducing agents + Examples 1-3 (sample 1 corresponds to Example 1, wherein the amount of water reducing agent added is 0.2%, and the water reducing agent of the present invention replaces 15% of the water reducing agent); comparative example It is a simple water reducer (commercially available conventional polycarboxylate water red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com