Combined ultrasonic whirl and disintegration process for surplus sludge

A technology of excess sludge and ultrasound, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of increased organic matter content in sludge, and reduce moisture content, The effect of solving disposal and processing problems, safe and reliable operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

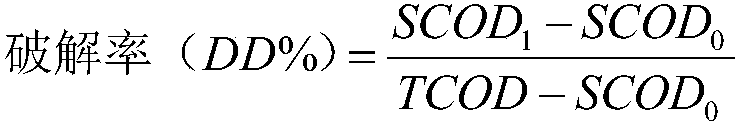

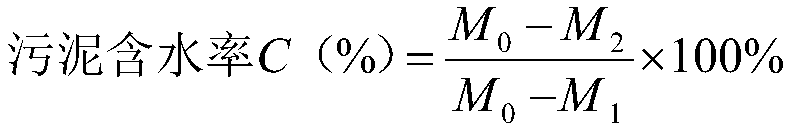

[0046] (1) After the excess sludge produced in the secondary sedimentation tank of the urban domestic sewage treatment plant is concentrated by gravity sedimentation, the moisture content of the sludge is 93.70%, the pH is 7.5, and the total solid content MLSS in the excess sludge is determined to be 1238mg / L , TCOD is 1478mg / L, of which soluble COD is 330mg / L, TN is 5.2mg / L, and TP is 0.22mg / L.

[0047] (2) Take 5L of residual sludge after gravity sedimentation concentration pretreatment and put it into the water inlet tank, use the cyclone alone to crack the residual sludge, and set the cyclone operating pressure of the inlet pressure gauge 5 to 0.1MPa and The cycle cracking time is 5min. After cracking, the residual sludge SCOD is 524mg / L, TN is 13.7mg / L, TP is 0.65mg / L, the sludge cracking rate is 16.89%, and the sludge moisture content is 92.78%.

Embodiment 2

[0049] (1) After the excess sludge produced in the secondary sedimentation tank of the urban domestic sewage treatment plant is concentrated by gravity sedimentation, the moisture content of the sludge is 93.70%, the pH is 7.5, and the total solid content MLSS in the excess sludge is determined to be 1238mg / L , TCOD is 1478mg / L, of which soluble COD is 330mg / L, TN is 5.2mg / L, and TP is 0.22mg / L.

[0050] (2) Take 5L of excess sludge that has been pretreated by gravity sedimentation and concentration and put it into an ultrasonic container, use ultrasonic waves alone to crack the excess sludge, and set the frequency of ultrasonic waves to 40kHz, power density to 0.07W / mL, and cavitation The time is 10min. At this time, the SCOD of the remaining sludge is 472mg / L, the TN is 8.1mg / L, the TP is 0.79mg / L, the sludge breakdown rate is 12.37%, and the sludge moisture content is 91.98%.

Embodiment 3

[0052] (1) After the excess sludge produced in the secondary sedimentation tank of the urban domestic sewage treatment plant is concentrated by gravity sedimentation, the moisture content of the sludge is 93.70%, the pH is 7.5, and the total solid content MLSS in the excess sludge is determined to be 1238mg / L , TCOD is 1478mg / L, of which soluble COD is 330mg / L, TN is 5.2mg / L, and TP is 0.22mg / L.

[0053] (2) Take 5L of the remaining sludge after gravity sedimentation concentration pretreatment and put it into the water inlet tank, set the swirl operating pressure of the inlet pressure gauge 5 to 0.1MPa, the ultrasonic frequency to 40kHz, and the power density to 0.07W / mL , after 5 minutes of circulating shear cracking by the hydrocyclone, the SCOD of the remaining sludge was 524mg / L, the TN was 13.7mg / L, the TP was 0.65mg / L, the sludge cracking rate was 16.89%, and the sludge moisture content was 92.78 %; Start the ultrasonic cavitation treatment again for 10 minutes. At this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com