Manual positioning and compressing self-locking mechanism for track trolley

A trolley and track technology, which is applied in the field of manual positioning and pressing self-locking mechanism of track trolley, can solve the problems of insufficient pressing force, cluttered pipelines, and large space occupation, so as to achieve improved stability, convenient operation, and convenient walking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

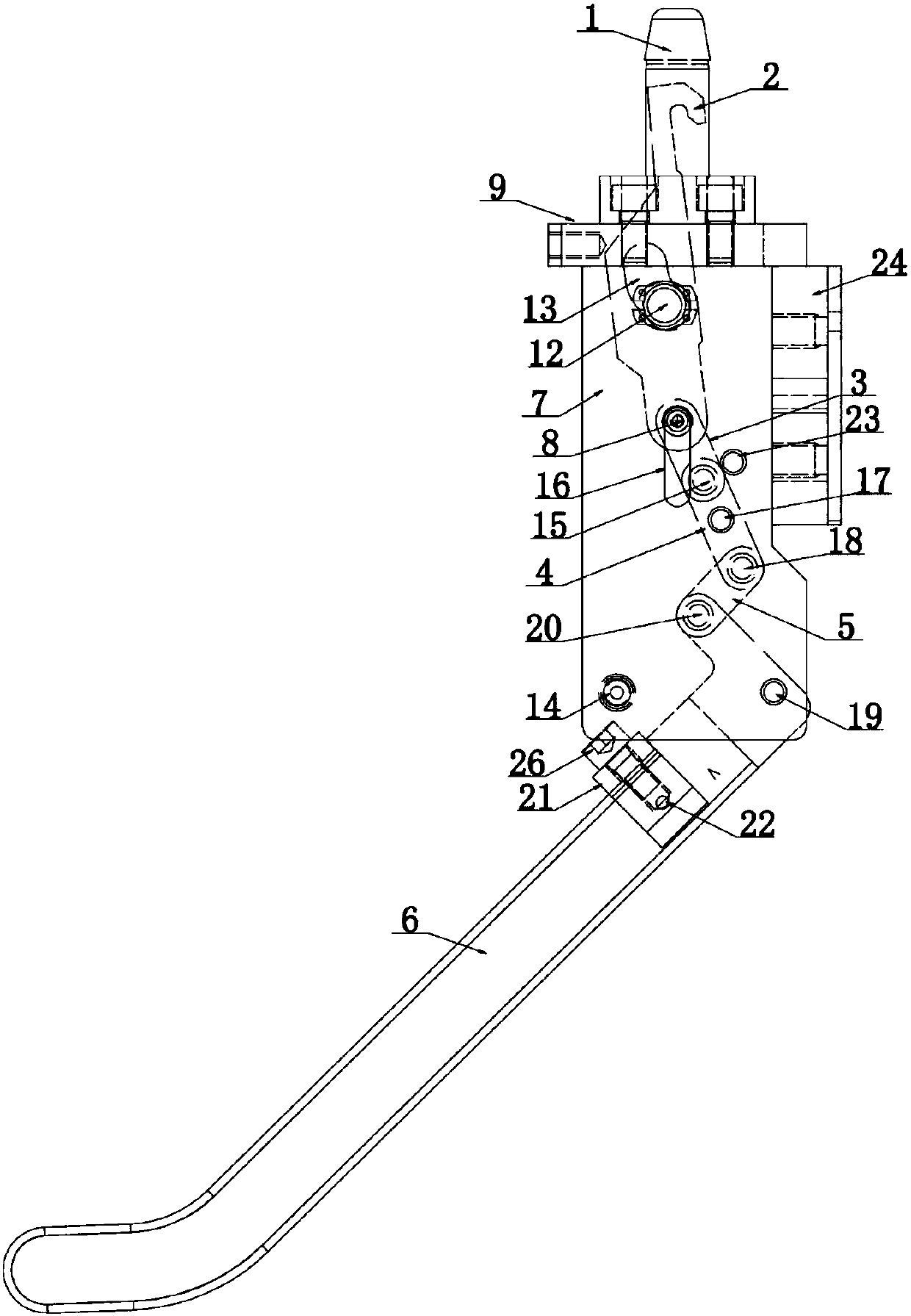

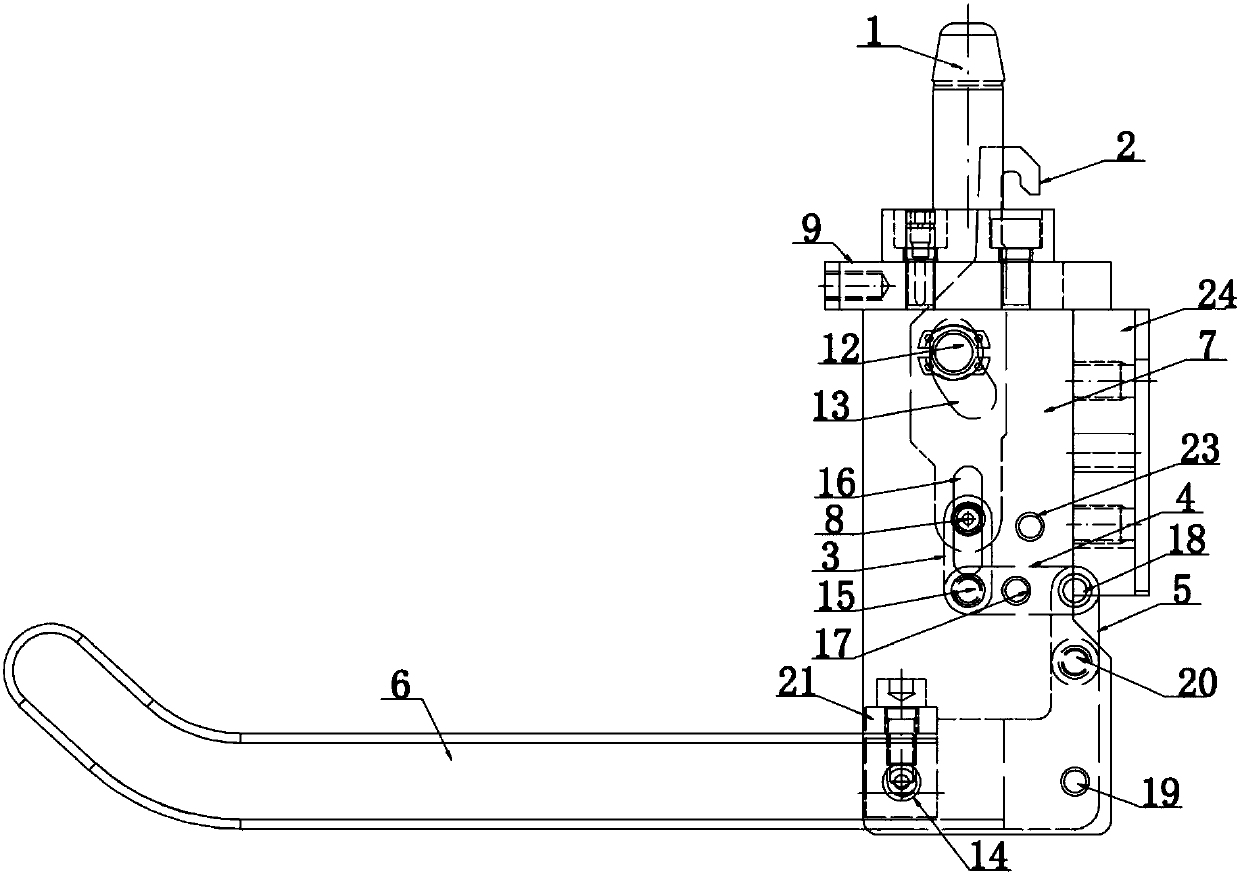

[0030] Example 1, such as Figure 1-Figure 4 As shown, a manual self-locking mechanism for vehicle body positioning includes a pair of support plates 7, a connecting plate 9, a hollow positioning pin 1, a pressing hook 2 and a connecting rod drive mechanism for driving the action of the pressing hook, and the connecting plate It is arranged on the top of a pair of said supporting plates, and said connecting plate is provided with a connecting plate groove 10 for said pressing hook to move, and said hollow positioning pin is arranged on the top of said connecting plate, and said hollow positioning pin There is a positioning pin groove 11 for the movement of the pressing hook inside, and the pressing hook is hinged with a pair of the support plates through the pressing hook pin shaft 12. The pressing hook through hole 13 matched with the hook pin shaft;

[0031] The connecting rod driving mechanism comprises a first connecting rod 3, a second connecting rod 4, a third connectin...

Embodiment 2

[0037] Example 2, such as Figure 5 and Figure 6 As shown, the pair of support plates are installed on the rail trolley through the rail trolley mounting seat 25, and the rail trolley mounting seat is provided with an adjusting bolt 27 for limiting the rocker. The mechanism can be installed on the rail trolley through the rail car mounting seat. When the rocker moves up, the elastic ball head snaps into the groove on the rocker to form a self-locking state. However, if the force is too large, there may be an over-position situation. In order to avoid excessive upward movement of the rocker and affect the self-locking effect, an adjustment bolt is set to adjust the extension length of the adjustment bolt so that the rocker shaft and the third hinge The three points of the axis and the second hinge axis are collinear, forming a mechanical dead point, and the pressing hook is pressed to achieve a self-locking state. The rocker located inside the support plate is blocked by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com