Multi-dielectric barrier discharge basic unit, reactor and waste gas treatment method

A basic unit and reactor technology, applied in the field of discharge basic units and reactors, can solve the problems of small discharge space, difficulty in uniform discharge, long gas residence time, etc., and achieve the effect of preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

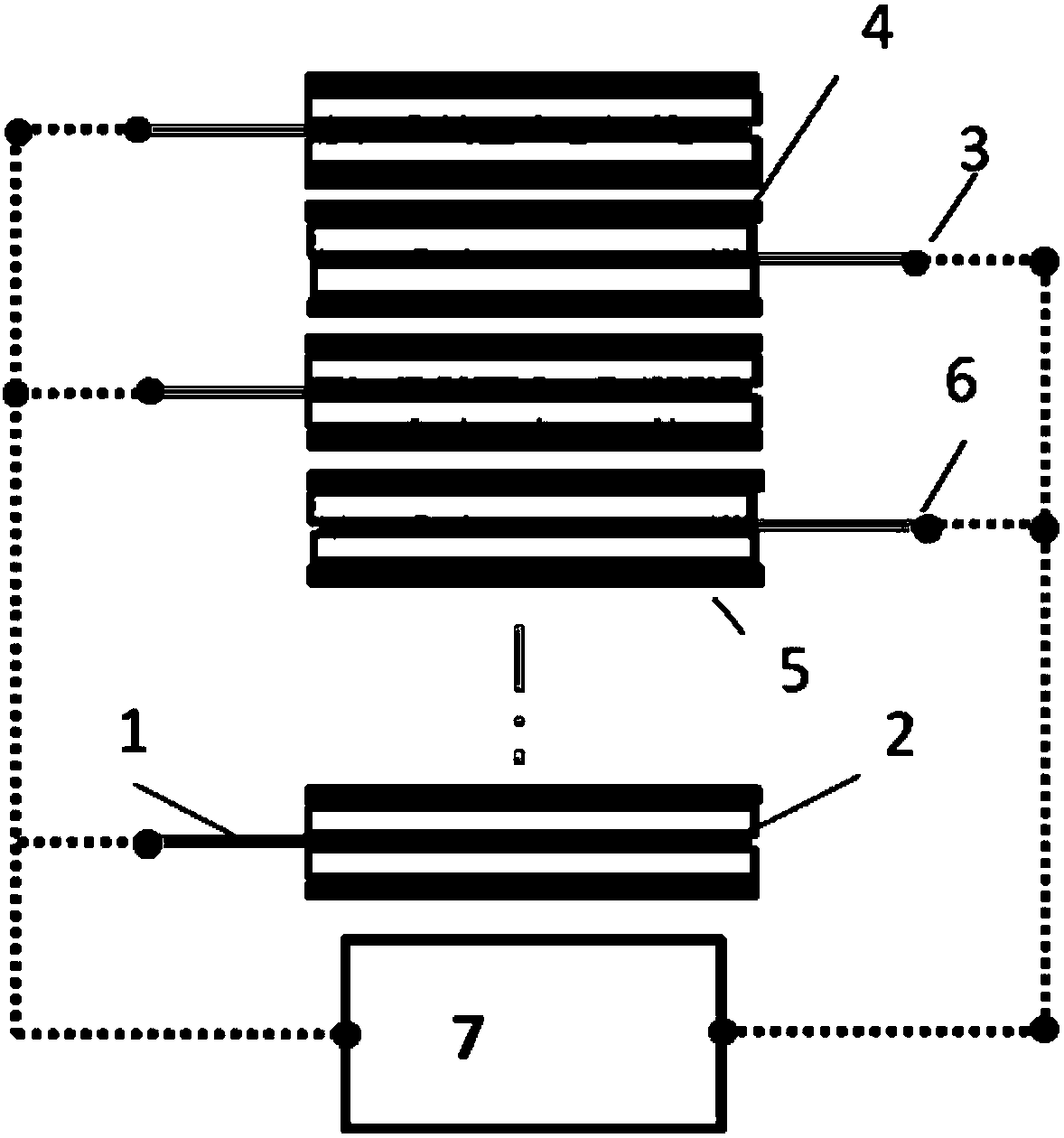

[0048] Such as image 3 In the flat-type multimedia barrier discharge reactor shown, the flat-type multimedia barrier discharge basic units are arranged in parallel, the electrodes are stainless steel, the first non-metallic medium is glue, the second non-metallic medium is porous aluminum oxide film, and the electrodes and electrodes The distance between them is 30mm, the power supply is a pulse power supply, the voltage is 25kV, and the frequency is 1000Hz. The thickness of the first non-metallic medium is 2mm, the thickness of the second non-metallic medium is 10 microns, the gas residence time is 10ms, the inlet of the discharge reactor is equipped with a defogging tower, and the outlet is equipped with an absorption tower with a circulating liquid pH value of 12 .

[0049] The experimental results in a harmless treatment plant show that the discharge is uniform when the gas in the discharge space is a dusty and odorous gas, and the corrosion of the dielectric barrier dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com