Preparation method of yolk-shell structure molybdenum disulfide@ carbon electrode material

A molybdenum disulfide and carbon electrode technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of difficult to control the size of voids, loss of electrode volume energy density/power density, and particle density reduction, etc. Uniform size, outstanding rate performance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

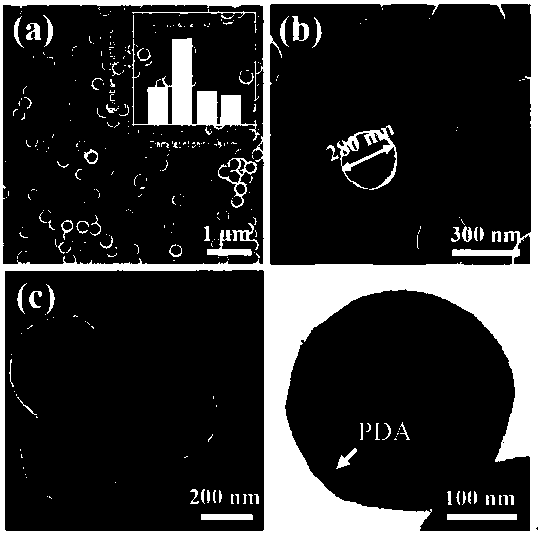

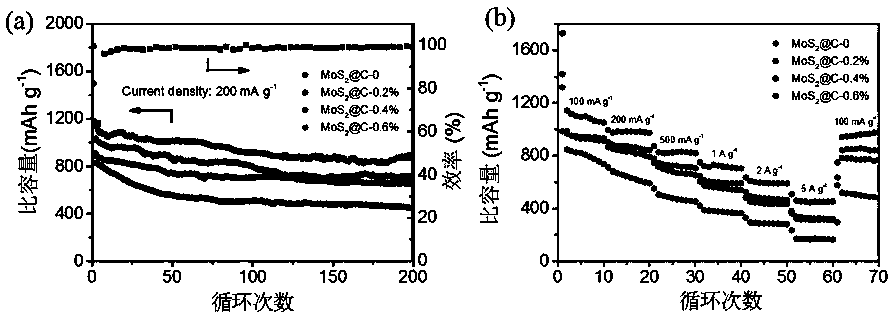

[0020] 1) Add 12 mmol of elemental sulfur and 5 mmol of molybdenum trioxide to 300 ml of ethylene glycol solution, and sonicate in a water bath for 10 minutes to form a homogeneous solution. Then transfer the above solution to a 500 ml polytetrafluoroethylene autoclave and put it in an oven at a temperature of 200°C for 12 hours to obtain molybdenum disulfide nanospheres.

[0021] 2) Disperse 800 mg of the above-mentioned molybdenum disulfide nanospheres in 200 ml of Tris buffer (10 mM, pH = 8.5), add 200 mg of dopamine and stir slowly for 12 h to obtain molybdenum disulfide@polydopamine. Put molybdenum disulfide@polydopamine into a tube furnace at a heating rate of 5 ℃ / min and a protective gas of N 2 、Carbonized at 800℃ for 2 h to obtain core-shell structure molybdenum disulfide@carbon (named MoS 2 @C-0%,).

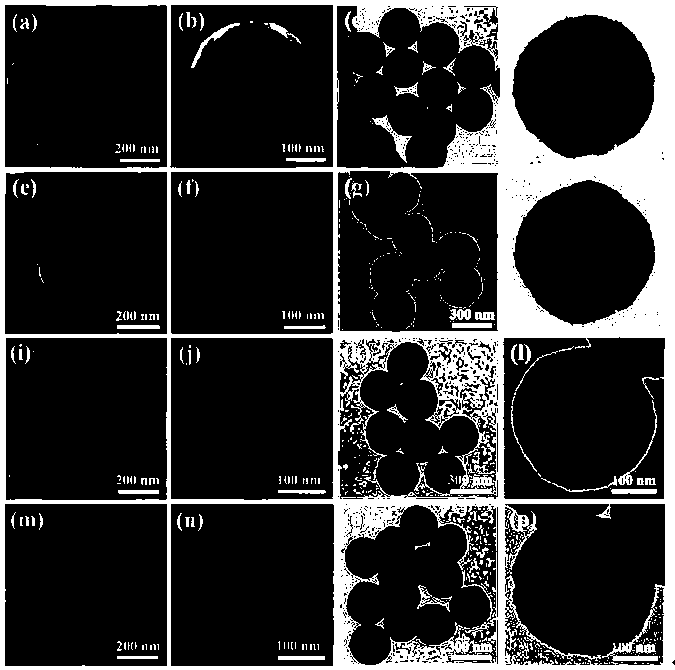

[0022] 3) Prepare a hydrogen peroxide solution with a concentration of 0.2 vol %, and then add 200 mg of the core-shell structure molybdenum disulfide@carbon, and stir vigoro...

Embodiment 2

[0025] 1) Add 12 mmol of elemental sulfur and 5 mmol of molybdenum trioxide to 300 ml of ethylene glycol solution, and sonicate in a water bath for 10 minutes to form a homogeneous solution. Then transfer the above solution to a 500 ml polytetrafluoroethylene autoclave and put it in an oven at a temperature of 200°C for 12 hours to obtain molybdenum disulfide nanospheres.

[0026] 2) Disperse 800 mg of the above-mentioned molybdenum disulfide nanospheres in 200 ml of Tris buffer (10 mM, pH = 8.5), add 200 mg of dopamine and stir slowly for 12 h to obtain molybdenum disulfide@polydopamine. Put molybdenum disulfide@polydopamine into a tube furnace at a heating rate of 5 ℃ / min and a protective gas of N 2 、Carbonized at 800℃ for 2 h to obtain core-shell structure molybdenum disulfide@carbon (named MoS 2 @C-0%,).

[0027] 3) Prepare a hydrogen peroxide solution with a concentration of 0.4 vol %, and then add 200 mg of the above core-shell structure molybdenum disulfide@carbon and stir v...

Embodiment 3

[0030] 1) Add 12 mmol of elemental sulfur and 5 mmol of molybdenum trioxide to 300 ml of ethylene glycol solution, and sonicate in a water bath for 10 minutes to form a homogeneous solution. Then transfer the above solution to a 500 ml polytetrafluoroethylene autoclave and put it in an oven at a temperature of 200 ℃ for 12 h to obtain molybdenum disulfide nanospheres.

[0031] 2) Disperse 800 mg of the above-mentioned molybdenum disulfide nanospheres in 200 ml of Tris buffer (10 mM, pH = 8.5), add 200 mg of dopamine and stir slowly for 12 h to obtain molybdenum disulfide@polydopamine. Put molybdenum disulfide@polydopamine into a tube furnace at a heating rate of 5 ℃ / min and a protective gas of N 2 、Carbonized at 800℃ for 2 h to obtain core-shell structure molybdenum disulfide@carbon (named MoS 2 @C-0%,).

[0032] 3) Prepare a hydrogen peroxide solution with a concentration of 0.6 vol %, then add 200 mg of the above core-shell structure molybdenum disulfide@carbon, and stir vigorous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com