Lithium metal negative pole preparation method, lithium metal negative pole and lithium battery

A technology for metal lithium and lithium batteries, which is applied in the preparation and application of stable metal lithium negative electrodes, can solve problems such as uneven deposition of lithium and uneven distribution of surface potential, and achieves the advantages of simple and easy method, excellent cycle performance and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of a stable metal lithium negative electrode:

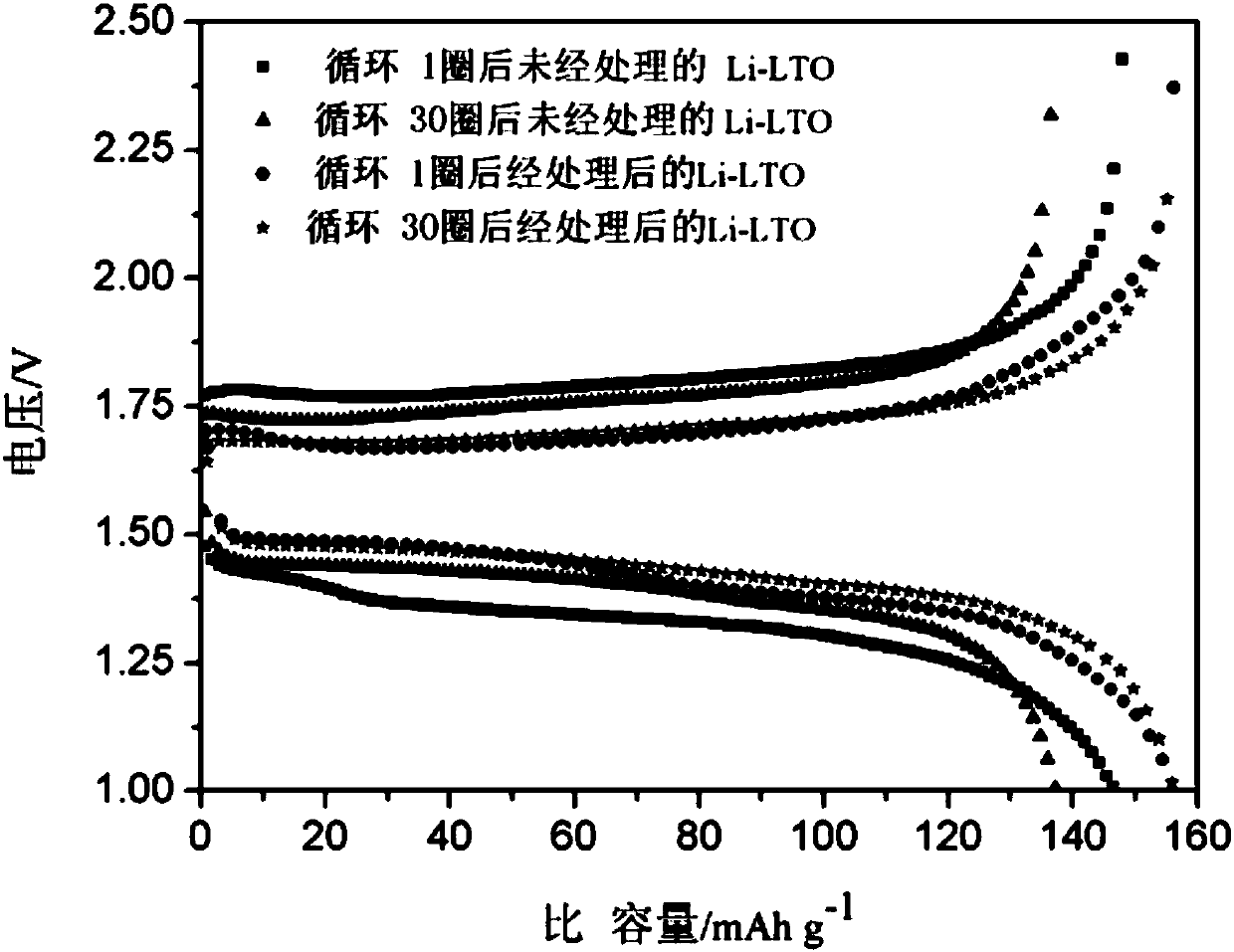

[0030] Accurately weigh 0.1g of polyvinylidene fluoride (PVDF) and fully dissolve in 3.4g of solvent N-methylpyrrolidone (NMP). After mixing evenly, add 0.1g of conductive carbon black and mix evenly. Add 0.8g of carbon fluoride and mix evenly. Stir Evenly coated on the copper foil current collector after overnight, punched and cut into 18mm pole piece; after drying, put the metal lithium piece and the carbon fluoride pole piece in sequence in the CR2016 button battery case, and add an appropriate amount of electrolyte LiPF 6 (EC:DMC 3:7), disassembled after standing for 24h, and obtained lithium metal sheet after processing, such as figure 1 After the treatment shown, there is a layer of gray substance on the surface of the metal lithium sheet, which may be the protective layer of lithium fluoride after the reaction. The metal lithium sheet after the treatment can be used as a stable metal lithium negativ...

Embodiment 2

[0037] The reaction time for preparing the stable metal lithium negative electrode is different, which is to stand still for 12 hours, and the rest are the same as in Example 1.

Embodiment 3

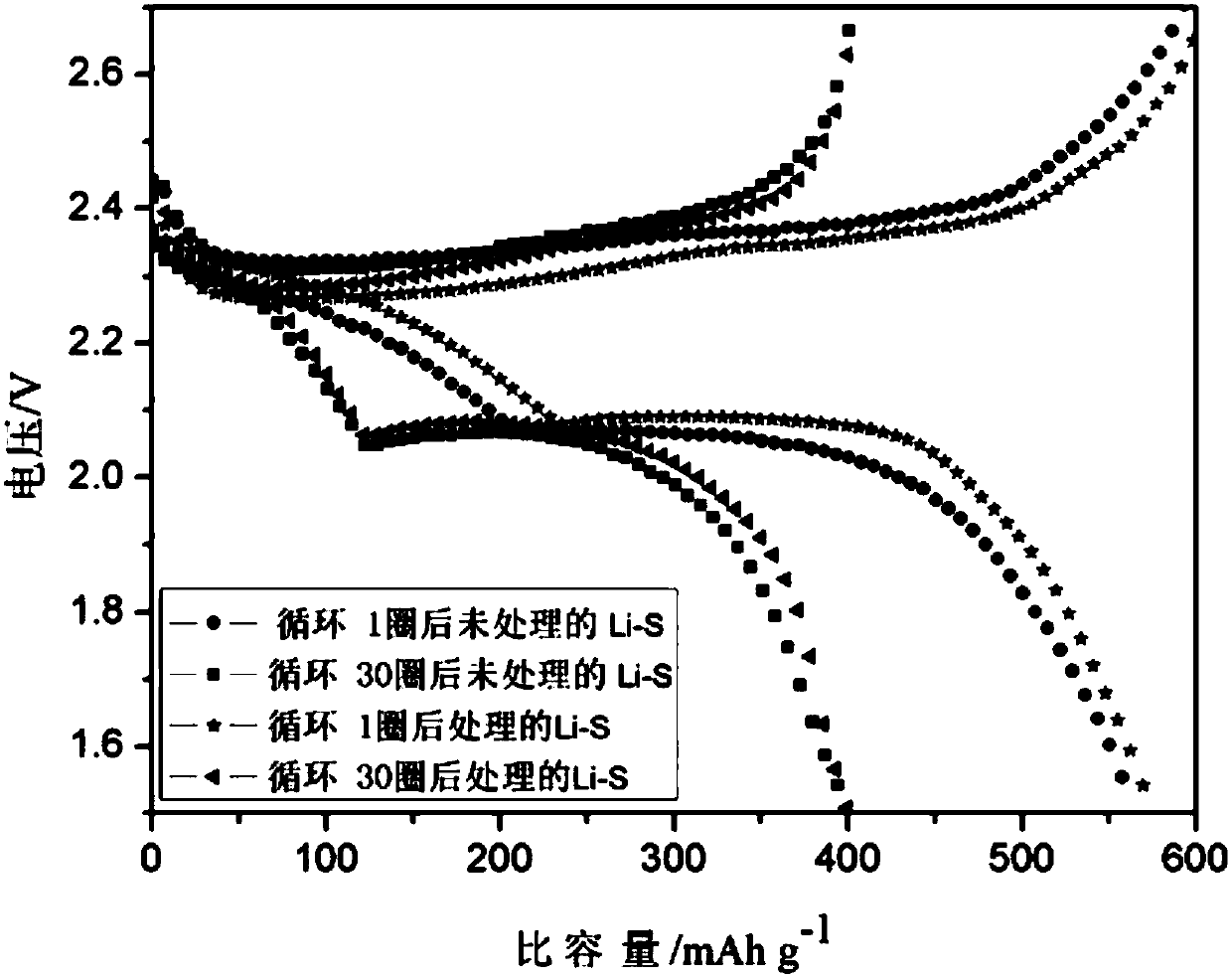

[0039] (1) Preparation of a stable metal lithium negative electrode:

[0040] Accurately weigh 0.1g PVDF and fully dissolve in 3.4g NMP, mix evenly, add 0.1g conductive carbon black, mix evenly, add 0.8g carbon fluoride, mix evenly, stir overnight and spread evenly on the copper foil current collector, die-cut into a 18mm pole piece; after drying, put the lithium metal sheet and the carbon fluoride pole piece in the CR2016 button battery case in sequence, and add an appropriate amount of electrolyte bistrifluoromethanesulfonamide lithium LiTFSI (ethylene glycol di Dimethyl ether (DME) / 1,3-dioxolane (DOL)), after standing for 24 hours, take it apart for use.

[0041] (2) Assemble metal lithium-sulfur battery (Li-S):

[0042] In the CR2016 button battery shell, put the processed metal lithium sheet, diaphragm and sulfur carbon pole piece in sequence, add an appropriate amount of electrolyte LiTFSI (DME / DOL), and compact it to obtain a stable metal lithium-sulfur battery.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com