A method for calibrating a coherence factor of an excimer lithographic lighting system

A kind of technology of excimer laser and illumination system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

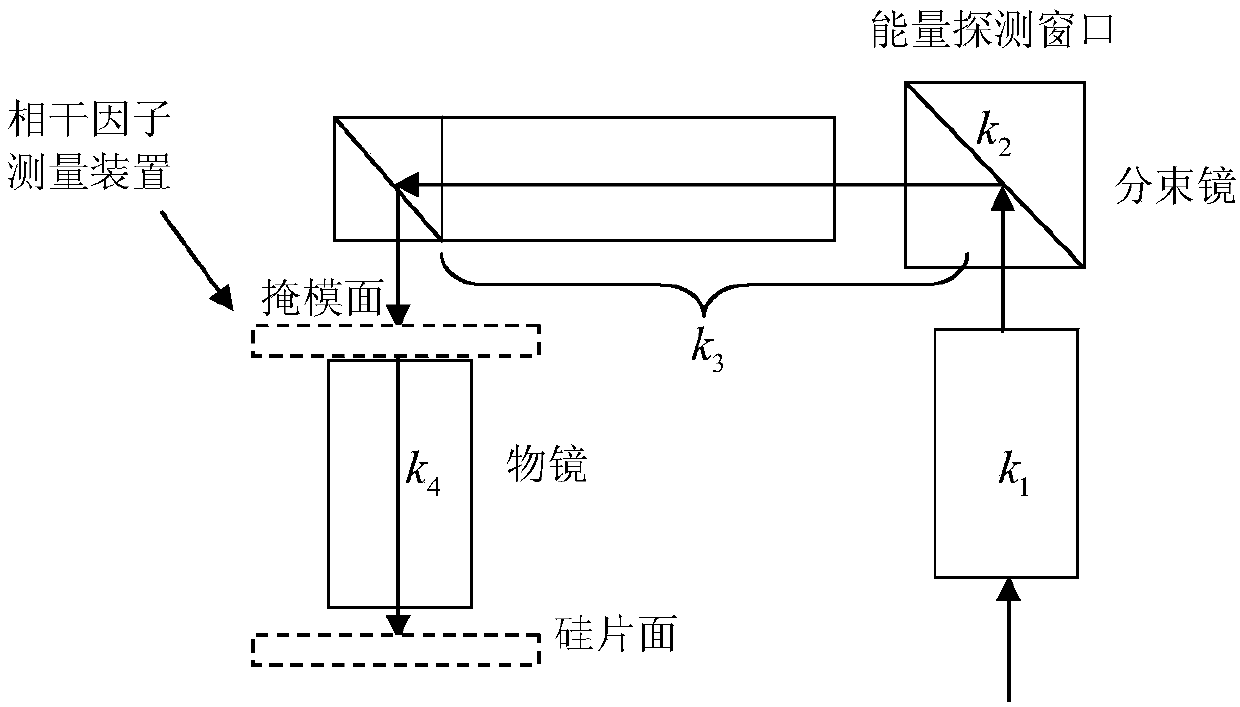

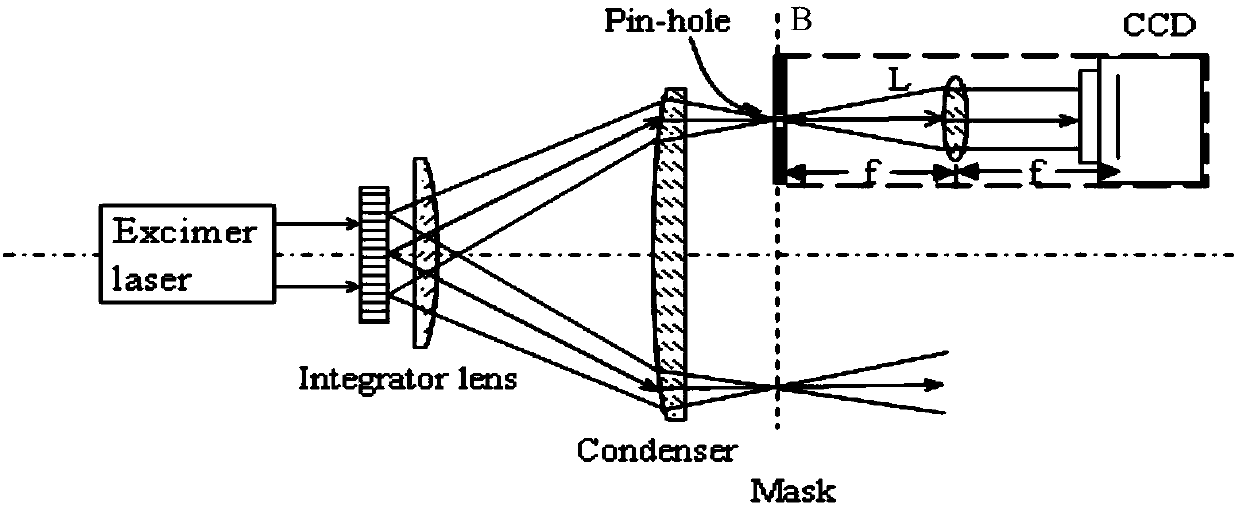

Method used

Image

Examples

Embodiment Construction

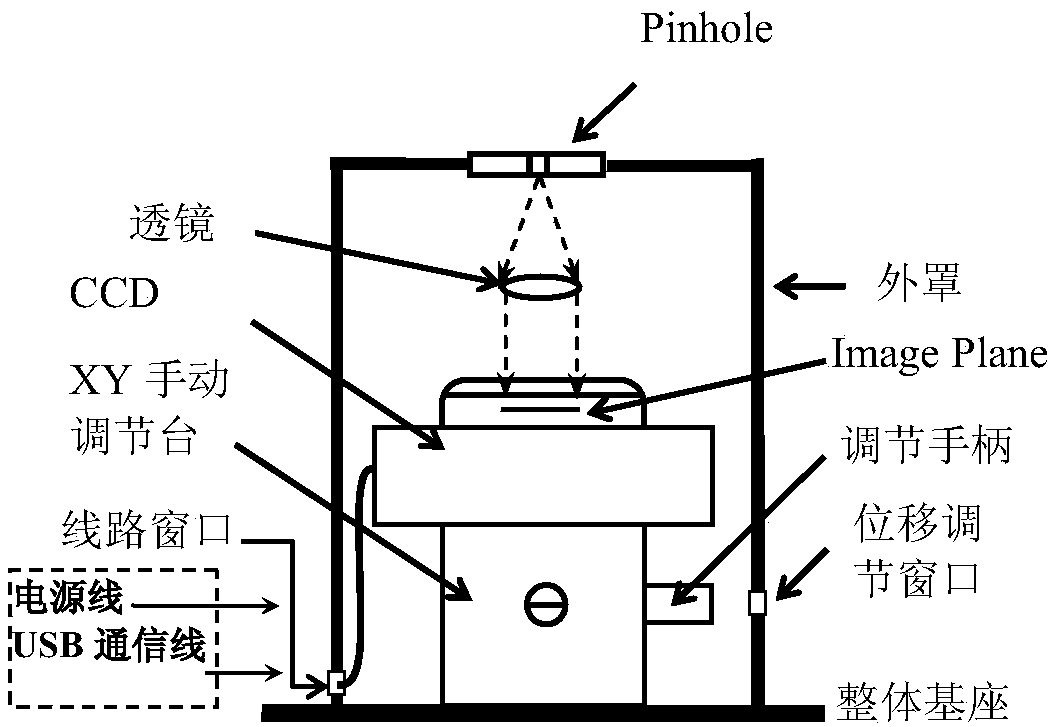

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and implementation methods.

[0020] exist Figure 4 In , after the pinhole and the lens group are fixed, a coordinate system is established on the lens , is the direction of the optical axis of the lens. Establish a coordinate system on the photosensitive surface of the CCD , Located in the photosensitive surface of CCD, is its normal direction, such as Figure 5 As shown, the corresponding unit vector . When the CCD photosensitive surface around shaft rotation angle, rotate around the Ym axis angle, coordinate system and The transformation matrix between is:

[0021] (1)

[0022] After rotation, the normal direction of the CCD photosensitive surface relative to the lens coordinates is,

[0023] (2)

[0024] for Figure 6 , there is a certain angle between the CCD photosensitive surface and the focal plane o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com