A low leakage connector

A connector and low-leakage technology, which is applied in the field of integrated circuit testing, can solve the problems of low-leakage test module connection, testing, and test efficiency drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

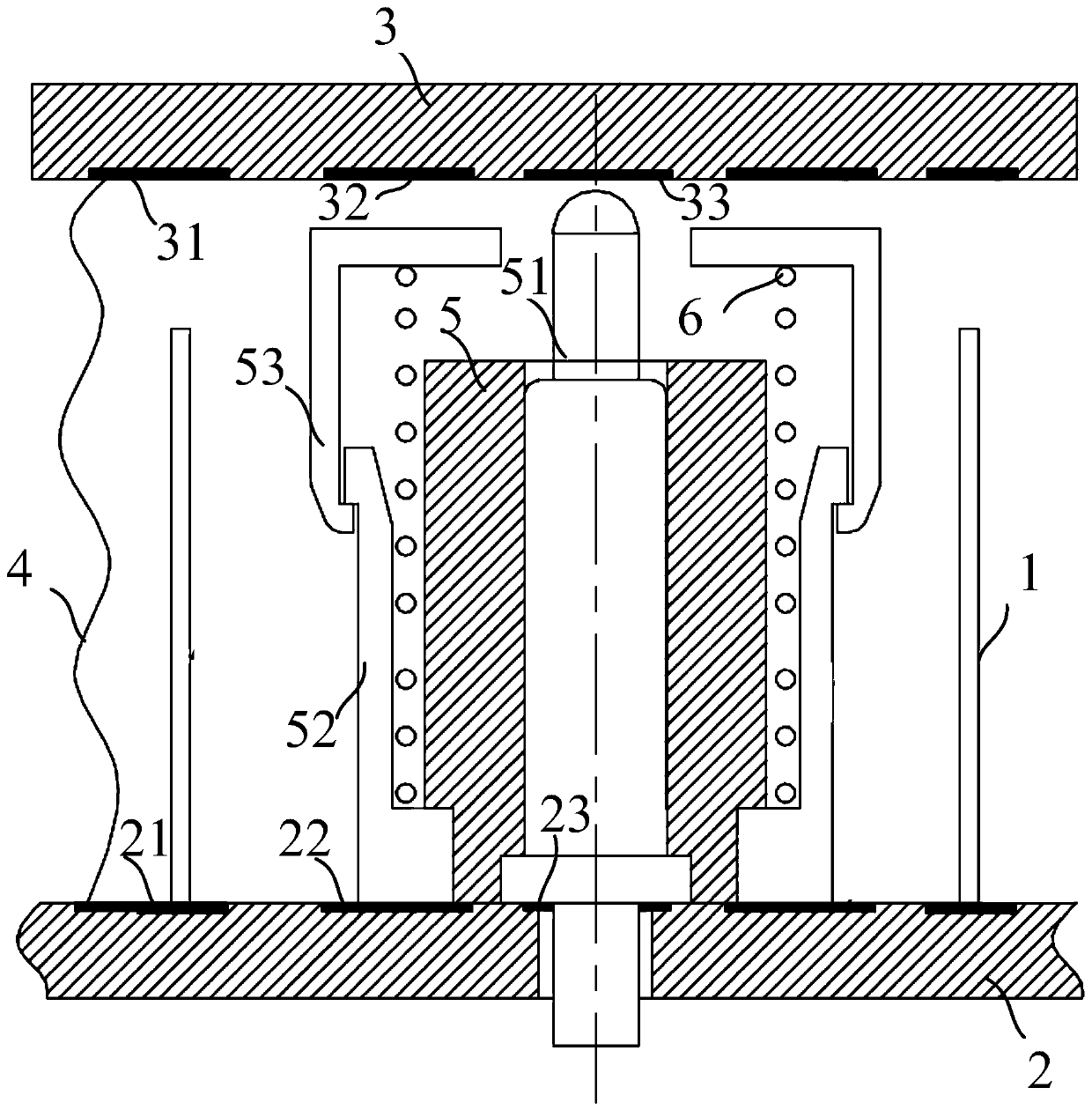

[0034] This embodiment provides a low leakage connector, such as figure 1 As shown, the low leakage connector includes: a plurality of retractable connection mechanisms, at least ground shielding mechanism 1; wherein,

[0035] One end of a plurality of said stretchable connection mechanisms is respectively connected to the first signal electrode 23 and the first equipotential electrode 22 of the first test substrate 2; the other end of said stretchable connection mechanism is respectively connected to the second test The second signal electrode 33 of the substrate 3 is connected to the second equipotential electrode 32; the ground shielding mechanism 1 is installed on the ground electrode 21 of the first test substrate 2 or on the ground electrode 31 of the second test substrate 3, for A plurality of said retractable mechanisms perform ground shielding. The ground shielding mechanism 1 is used to shield the retractable connection mechanism and eliminate the influence of exter...

Embodiment 2

[0056] In practical applications, the number of low-leakage connectors can be determined according to the number of PIN pins to be tested on the test substrate. The low-leakage connector provided in Embodiment 1 performs a connection test on each PIN pin, and the specific implementation is as follows:

[0057] The low-leakage connector includes 6 (because the first test substrate 2 and the second test substrate 3 are divided into 6 test cavities), the ground shielding mechanism 1; wherein,

[0058] see figure 1 , one end of the telescopic connection mechanism is connected to the first signal electrode 23 and the first equipotential electrode 22 of the first test substrate 2 respectively; the other end of the telescopic connection mechanism is respectively connected to the second test substrate The second signal electrode 33 of 3 is connected to the second equipotential electrode 32; the ground shielding mechanism 1 is installed on the ground electrode 21 of the first test sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com