Efficient electroplating device capable of achieving complete plating layer

An electroplating device and comprehensive technology, applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems affecting the electroplating quality of metal workpieces, the difference in electrolyte concentration, and the incomplete electroplating of metal workpieces, etc. Electroplating effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

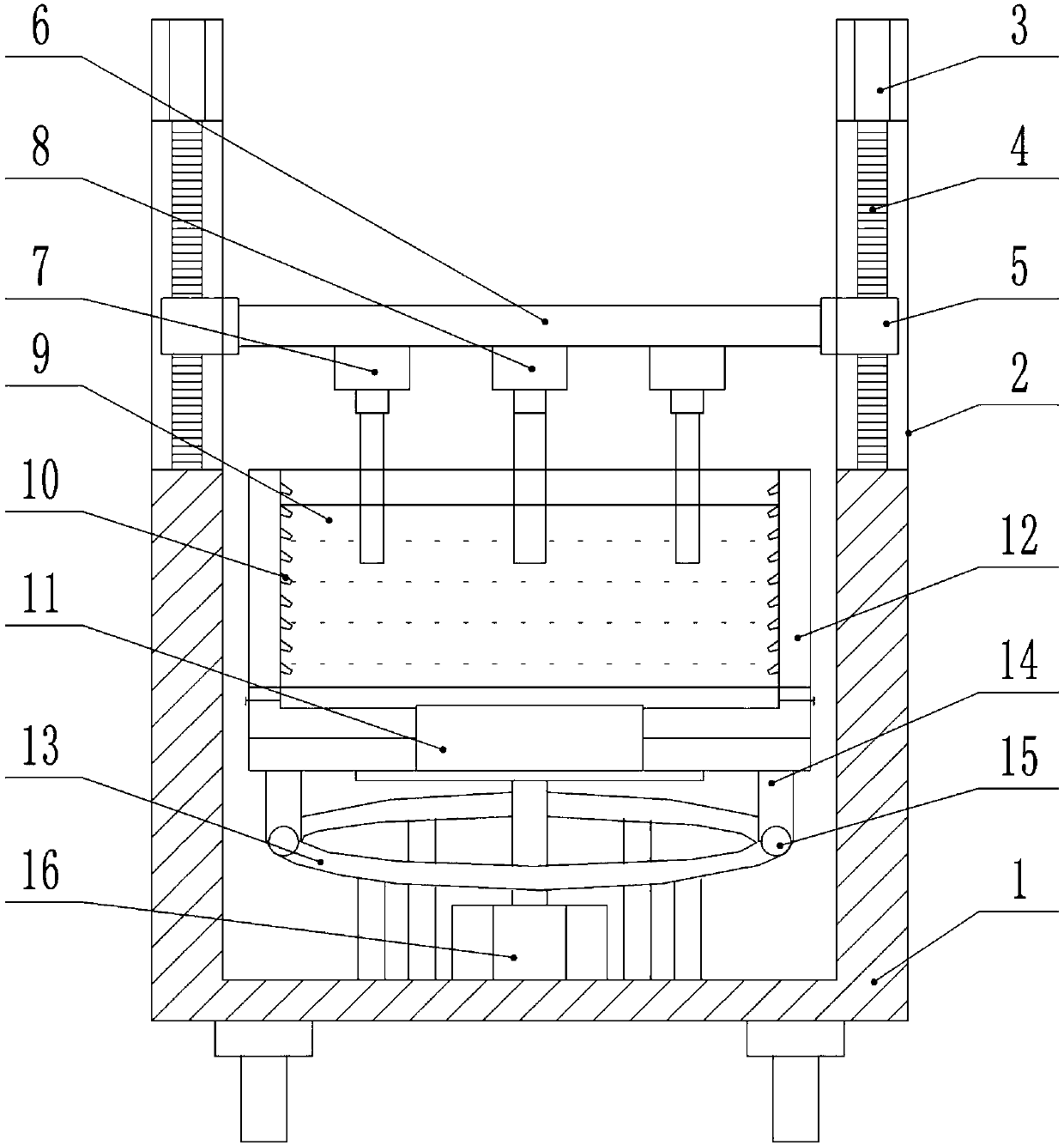

[0016] like figure 1 As shown, a comprehensive and efficient electroplating device for coating comprises a frame 1, and is characterized in that the bottom of the frame 1 is horizontally provided with an annular track 13, and the bottom of the annular track 13 is installed on the Above the bottom of the frame 1, the central axis of the annular track 13 coincides with the central axis of the frame 1, and an electroplating tank 9 is arranged above the annular track 13, and the electroplating tank 9 has a hollow cylindrical structure Set, the electroplating tank 9 is provided with electroplating solution, and the outside of the bottom of the electroplating tank 9 is vertically connected with several legs 14, and the bottom of the legs 14 is installed in the track of the circular track 13 by rollers 15, The roller 15 is adapted to the track of the circular track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com