Metal pipe fitting surface electroplating equipment

A technology of electroplating equipment and metal pipe fittings, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of incomplete electroplating, inconvenient electroplating of metal pipes of different lengths, and easy generation of air bubbles in metal pipes, so as to avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

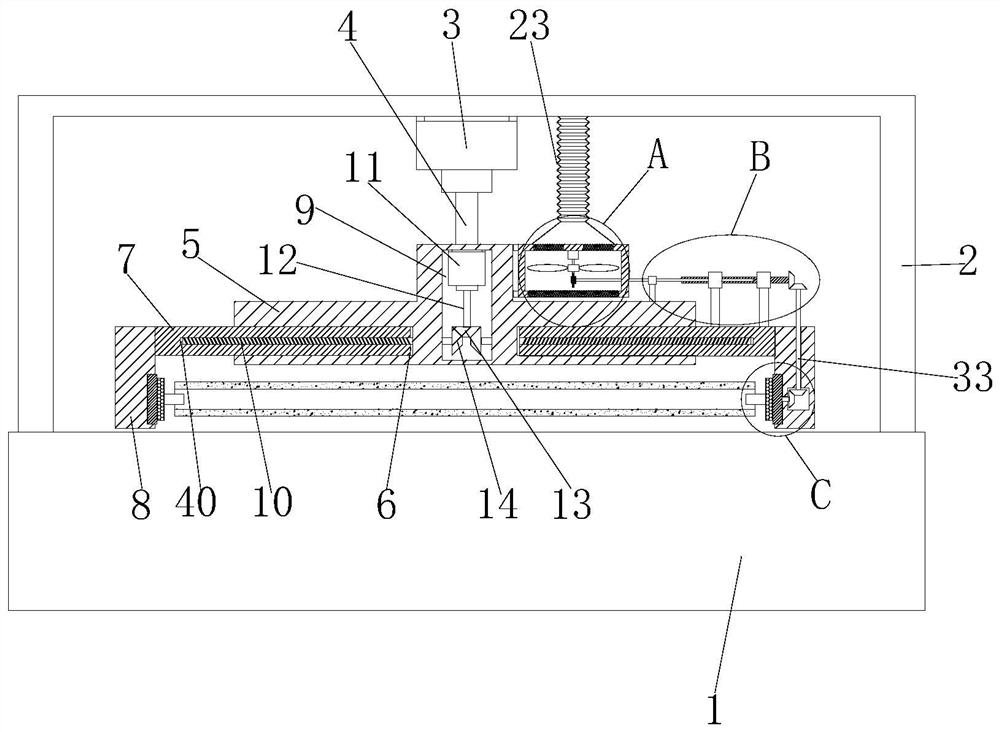

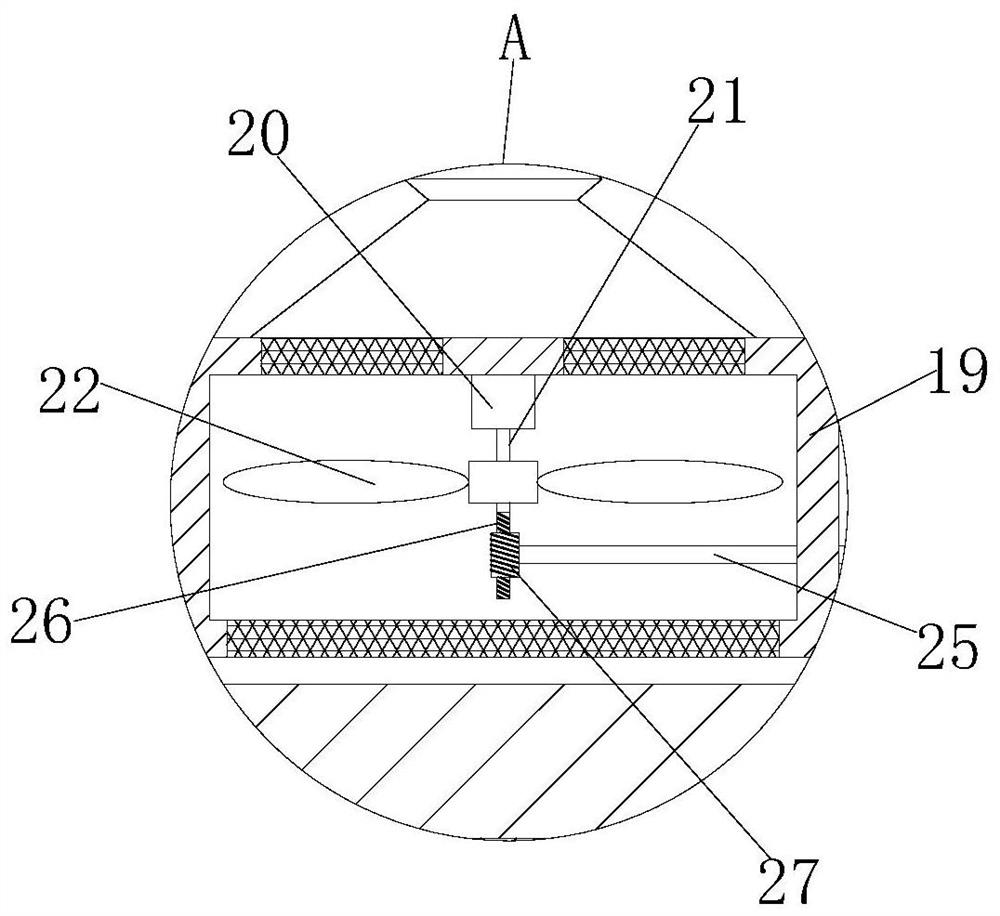

[0029] refer to Figure 1-5 , a surface electroplating equipment for metal pipe fittings, comprising an electroplating pool 1, a mounting frame 2 is fixedly installed on the top of the electroplating pool 1, a hydraulic cylinder 3 is fixedly mounted on the mounting frame 2, and a hydraulic telescopic rod is welded on the output shaft of the hydraulic cylinder 3 4. The bottom end of the hydraulic telescopic rod 4 is fixedly connected with a cross bar 5, and both ends of the cross bar 5 are provided with a first rectangular chute 6, and a telescopic mechanism is slidably installed in the two first rectangular chute 6, and the telescopic mechanism The sides close to each other are all provided with a sealing clamping mechanism, and the top of the cross bar 5 is provided with an exhaust mechanism, and the exhaust mechanism cooperates with the sealing clamping mechanism.

[0030] In this embodiment, the telescopic mechanism includes a first rectangular rod 7 and a connecting plate ...

Embodiment 2

[0040] refer to Figure 1-5 , a surface electroplating equipment for metal pipe fittings, comprising an electroplating pool 1, a mounting frame 2 is fixedly installed on the top of the electroplating pool 1 by welding, a hydraulic cylinder 3 is fixedly installed on the mounting frame 2 by bolts, and the output shaft of the hydraulic cylinder 3 is welded There is a hydraulic telescopic rod 4, and the bottom end of the hydraulic telescopic rod 4 is fixedly connected with a crossbar 5 by welding, and both ends of the crossbar 5 are provided with a first rectangular chute 6, and the two first rectangular chute 6 are slidingly installed There is a telescopic mechanism, and the side close to each other of the telescopic mechanisms is provided with a sealing clamping mechanism, and the top of the cross bar 5 is provided with an exhaust mechanism, and the exhaust mechanism cooperates with the sealing clamping mechanism.

[0041] In this embodiment, the telescopic mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com