Anti-cavitation laser cladding construction method for water pump turbines suitable for power station sites

A water pump turbine, laser cladding technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of expanding application, small size, and easy on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 cladding Ni60+WC composite coating on martensitic stainless steel

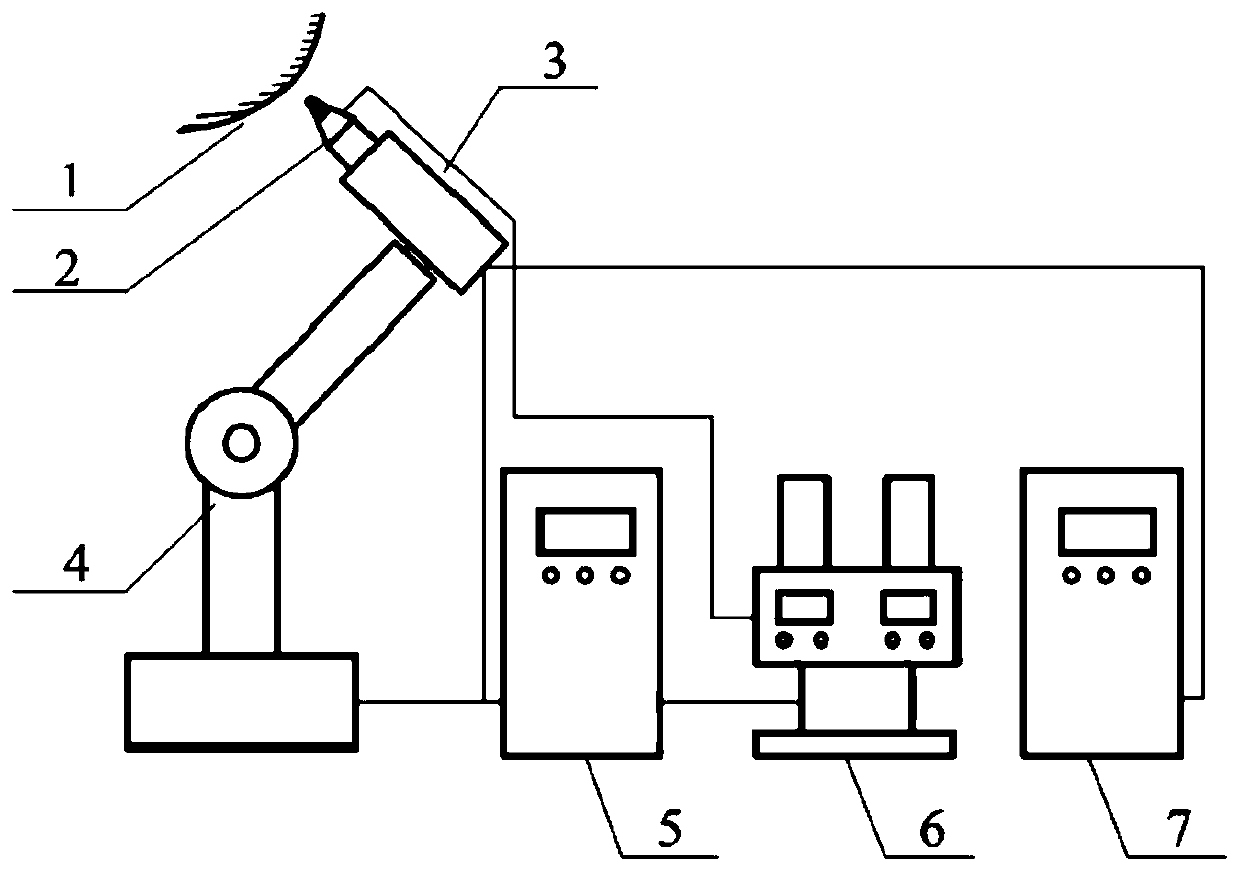

[0058] 1) Preliminary preparation: see figure 1 Install and debug the cladding system.

[0059] In this example, the substrate sample is 12mm thick wire-cut to a size of 100×60mm, ultrasonically cleaned with absolute ethanol for 10 minutes, sand blasted and then ultrasonically cleaned with acetone for 10 minutes before use. In this example, the cladding surface is at the 100° orientation in the vertical plane, the horizontal direction is 0°, and the counterclockwise direction is the positive direction. A programmable robot is used to align the laser and the powder feeding head on the cladding surface. Cause damage, the laser and the powder feeding head are in the 70° orientation, adjust the distance between the powder feeder and the substrate to ensure that the laser defocus is positive defocus 13mm. Choose laser power 700W, cladding speed 250mm / min, overlap rate 40%, and cladding area 80...

Embodiment 2

[0062] Embodiment 2 Cladding Ni60 coating on martensitic stainless steel

[0063] 1) Preliminary preparation: see figure 1 Install and debug the cladding system. In this example, the substrate sample is 12mm thick wire-cut to a size of 100×60mm, ultrasonically cleaned with absolute ethanol for 10 minutes, sand blasted and then ultrasonically cleaned with acetone for 10 minutes before use. In this example, the cladding surface is at the 100° orientation in the vertical plane, the horizontal direction is 0°, and the counterclockwise direction is the positive direction. Use the robot to align the laser and the powder feeding head on the cladding surface, in order to prevent the laser reflection from causing damage to the laser , the laser and the powder feeding head are in a 70° orientation, and the distance between the laser and the substrate is adjusted to ensure that the laser defocus is positive defocus of 13mm. Choose laser power 700W, cladding speed 250mm / min, overlap rat...

Embodiment 3

[0065] Example 3 Cladding Ni60+WC Composite Coating on Martensitic Stainless Steel

[0066] 1) Preliminary preparation: see figure 1 Install and debug the cladding system. In this example, the substrate sample is 12mm thick wire-cut to a size of 100×60mm, ultrasonically cleaned with absolute ethanol for 10 minutes, sand blasted and then ultrasonically cleaned with acetone for 10 minutes before use. In this example, the cladding surface is at the 100° orientation in the vertical plane, the horizontal direction is 0°, and the counterclockwise direction is the positive direction. Use the robot to align the laser and the powder feeding head on the cladding surface, in order to prevent the laser reflection from causing damage to the laser , the laser and the powder feeding head are in a 70° orientation, and the distance between the laser and the substrate is adjusted to ensure that the laser defocus is positive defocus of 13mm. Choose laser power 700W, cladding speed 250mm / min, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com