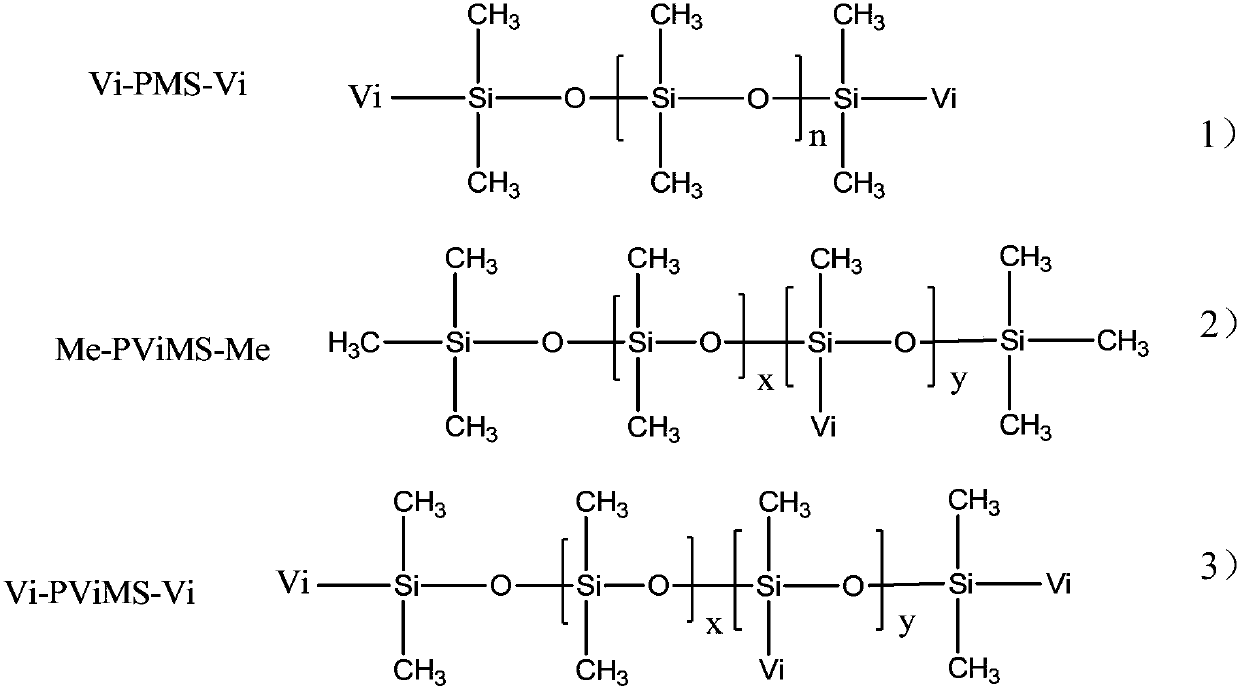

Vinyl polysiloxane as well as preparation method and application thereof

A technology of vinyl polysiloxane and base cyclosiloxane, applied in directions without pigment coating, etc., can solve problems such as affecting the yield of vinyl polysiloxane, achieve molecular weight and easy control, low production cost, Highly reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of vinyl polysiloxane, comprising the following steps:

[0038]Put 19.6g of DMC (Hubei New Sihai Chemical Co., Ltd.) and 5.2g of tetramethyltetravinylcyclotetrasiloxane (Bailingwei) in a reaction vessel, raise the temperature to 80°C, stir and evacuate to -0.09MPa, and dehydrate for 1h , to obtain a dehydrated monomer mixture; add 1.82g of divinyltetramethyldisiloxane to the dehydrated monomer mixture, and heat up to 100°C; add 0.49g of temporary catalyst tetramethylammonium hydroxide, and heat up to 110°C, Heat preservation reaction for 1 hour; raise the temperature to 120°C, heat preservation reaction for 3 hours; heat up to 130°C, heat preservation reaction for 1 hour to obtain the reaction product; heat the reaction product to 180°C to decompose the catalyst, vacuum -0.09MPa nitrogen, until there is no fraction distillation Go out, obtain colorless and transparent product vinyl polysiloxane. The conversion rate of the monomer in this example is...

Embodiment 2

[0040] A preparation method of vinyl polysiloxane, comprising the following steps:

[0041] Put 27g of DMC (Hubei New Sihai Chemical Co., Ltd.) and 6.2g of tetramethyltetravinylcyclotetrasiloxane in a three-necked flask, raise the temperature to 80°C, stir and evacuate to -0.09MPa, and dehydrate for 1h to obtain a dehydrated single monomer mixture; add 3.6g of divinyltetramethyldisiloxane to the dehydrated monomer mixture, and heat up to 100°C; add 0.56g of temporary catalyst tetramethylammonium hydroxide, heat up to 110°C, and keep warm for 1h; Raise the temperature to 120°C, heat-retain for 3 hours; raise the temperature to 130°C, heat-retain for 1 hour, and obtain the reaction product; heat the reaction product to 180°C, decompose the catalyst, vacuumize -0.09MPa and blow nitrogen until no fraction distills out to obtain Colorless transparent product vinyl polysiloxane. The conversion rate of the monomer in this example is 91.2%.

Embodiment 3

[0043] A preparation method of vinyl polysiloxane, comprising the following steps:

[0044] Put 19.6g of DMC (Hubei New Sihai Chemical Co., Ltd.) and 5.2g of tetramethyltetravinyl cyclotetrasiloxane in a three-necked flask, raise the temperature to 80°C, stir and evacuate to -0.09MPa, and dehydrate for 1 hour to obtain dehydrated Monomer mixture; add 1.82g of divinyltetramethyldisiloxane to the dehydrated monomer mixture, heat up to 90°C; add 0.49g of temporary catalyst tetramethylammonium hydroxide, heat up to 110°C, keep warm for 1h Raise the temperature to 120°C and keep it warm for 3 hours; raise the temperature to 130°C and keep it warm for 1 hour to obtain the reaction product; raise the temperature of the reaction product to 180°C to decompose the catalyst, vacuumize -0.09MPa and blow nitrogen until no fraction distills out. A colorless and transparent product vinyl polysiloxane was obtained. The conversion rate of the monomer in this example is 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com