Self-avoidance device and method for cantilever rail to pass through narrow deep cavity members

A cantilever and rail technology, applied in maintenance and safety parts, metal processing machinery parts, large fixed members, etc., can solve the problems of cumbersome use of traversing devices, difficult to automate, insufficient rigidity of cantilever rails, etc., to achieve the realization of numerical control and automation, Achieve fully automated, increased stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

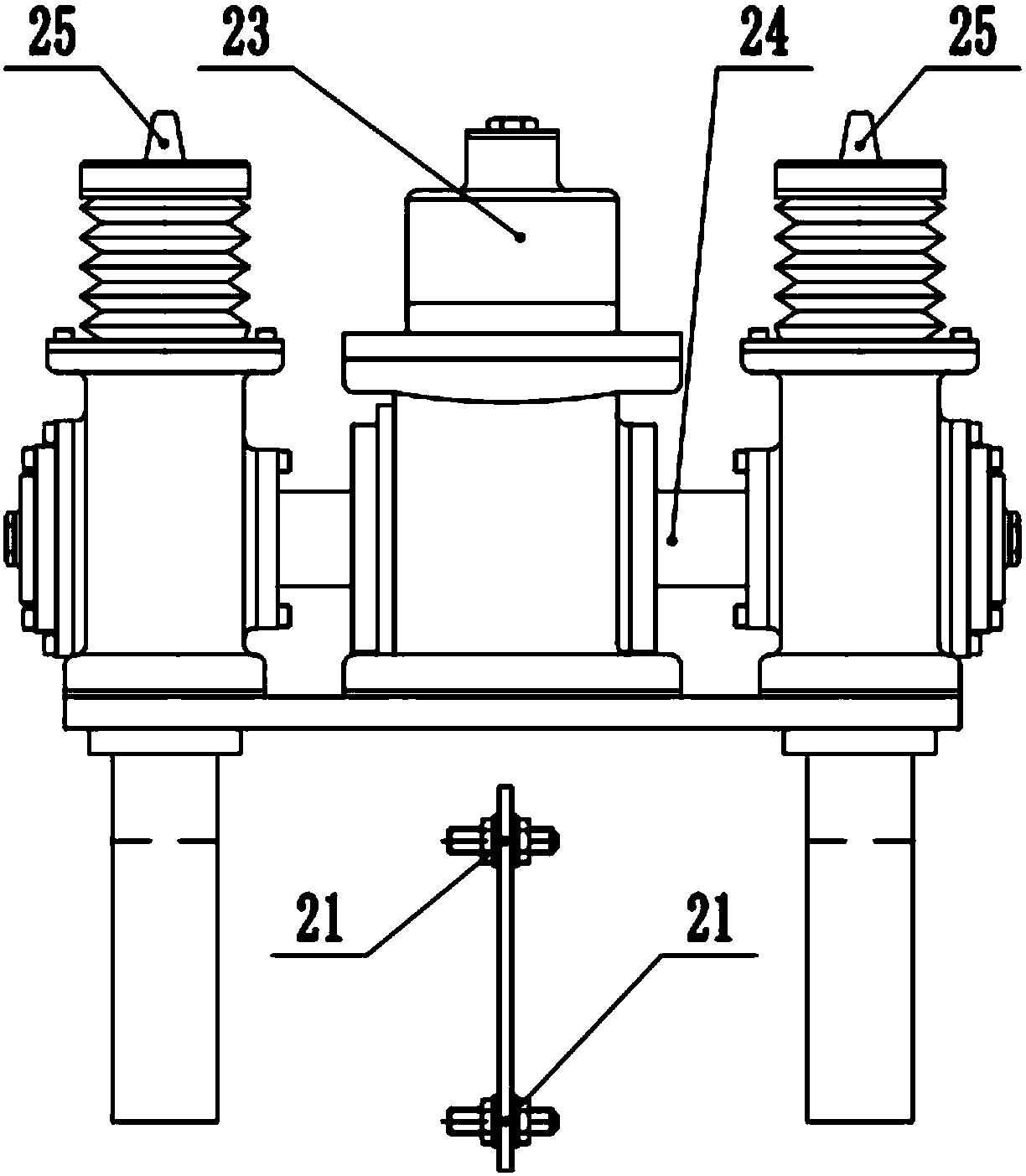

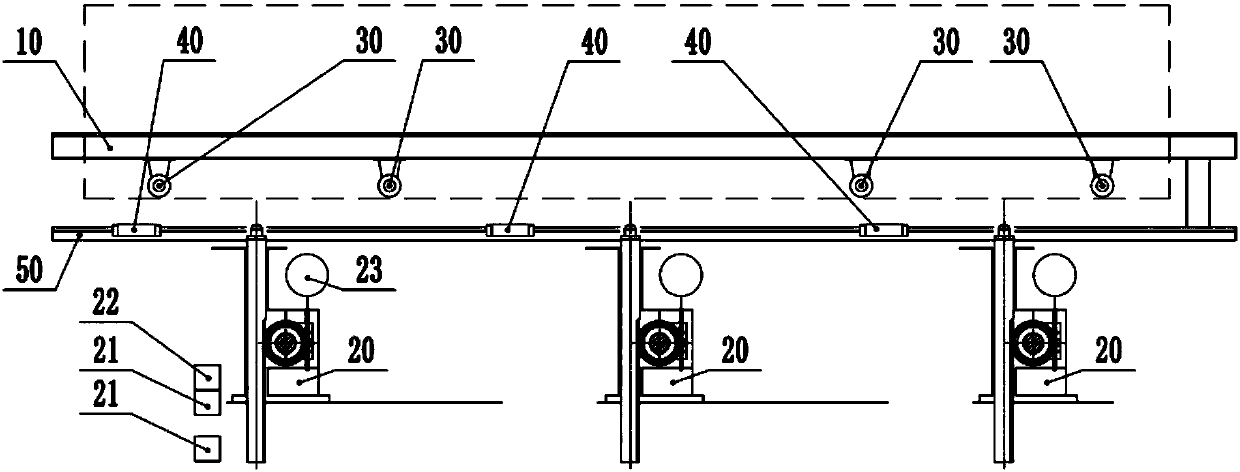

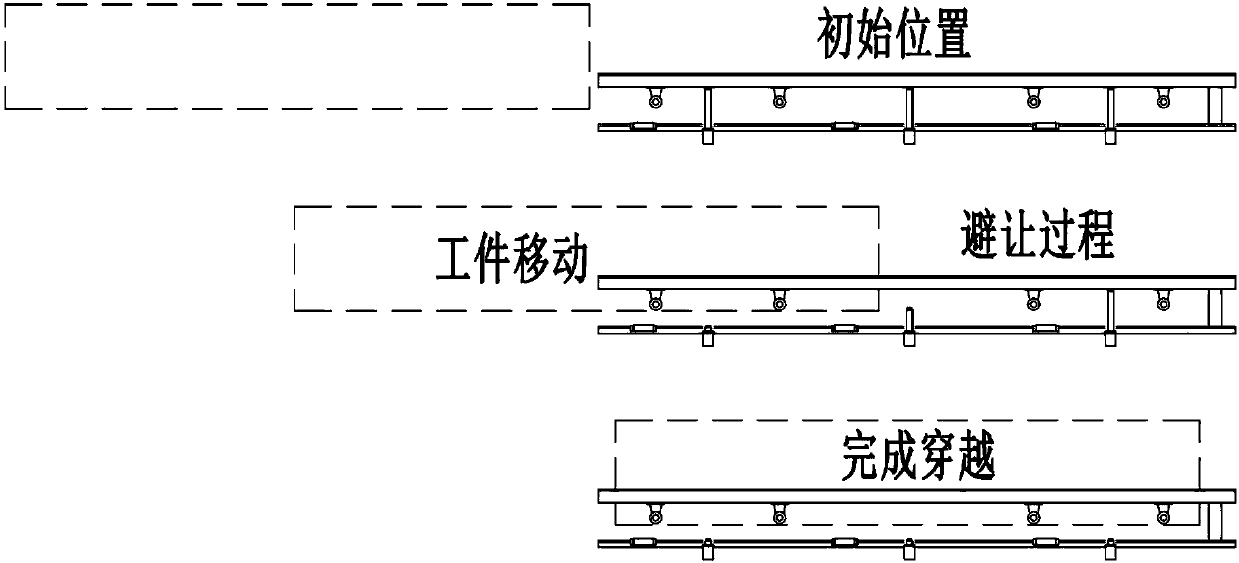

[0030] Such as Figure 1-4 As shown, the self-avoiding device for the cantilever track passing through the narrow and long deep cavity components includes: the cantilever guide rail 10, the self-avoiding alternate support mechanism group 20, the auxiliary support wheel group 30, the position sensor group 40, and the equipment base 50; the position sensor group 40 Installed on the equipment base 50; the auxiliary support wheel set 30 is installed on the bottom of the cantilever track 10; the position sensor group 40 includes a plurality of identical sensors (this embodiment includes 3 sensors), which are respectively installed in sequence on the equipment On different positions of the base 50; the self-avoiding support mechanism group 20 includes a plurality of self-avoiding support units (this embodiment includes 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com