Rubber sleeve for mandrel of cold rolling coiler

A technology for rubber sleeves and shafts, applied in the field of cold-rolled coilers, can solve problems such as short service life, structural failure, and reduced production efficiency, and achieve the effects of large friction coefficient, good rebound, and reduced head marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

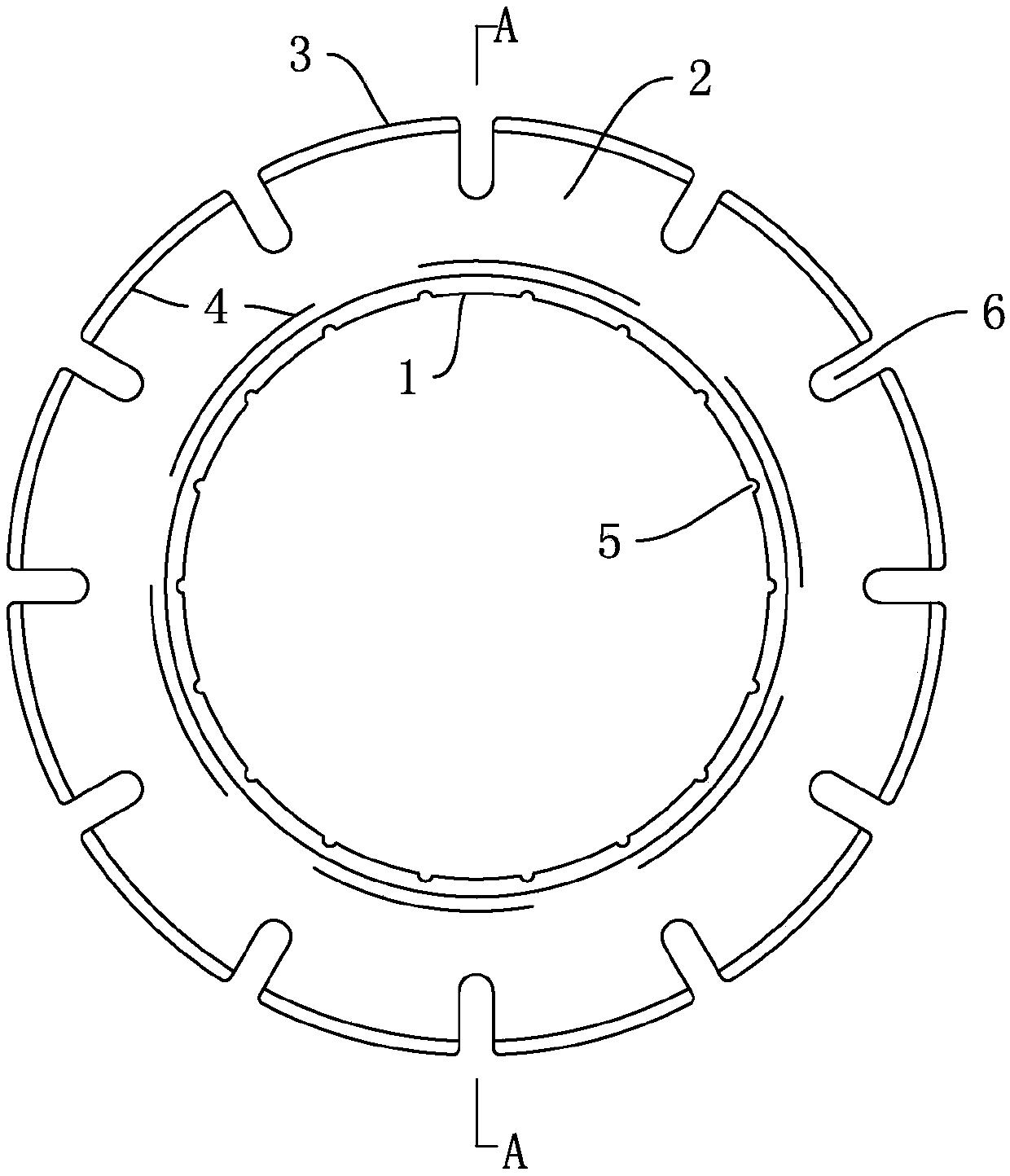

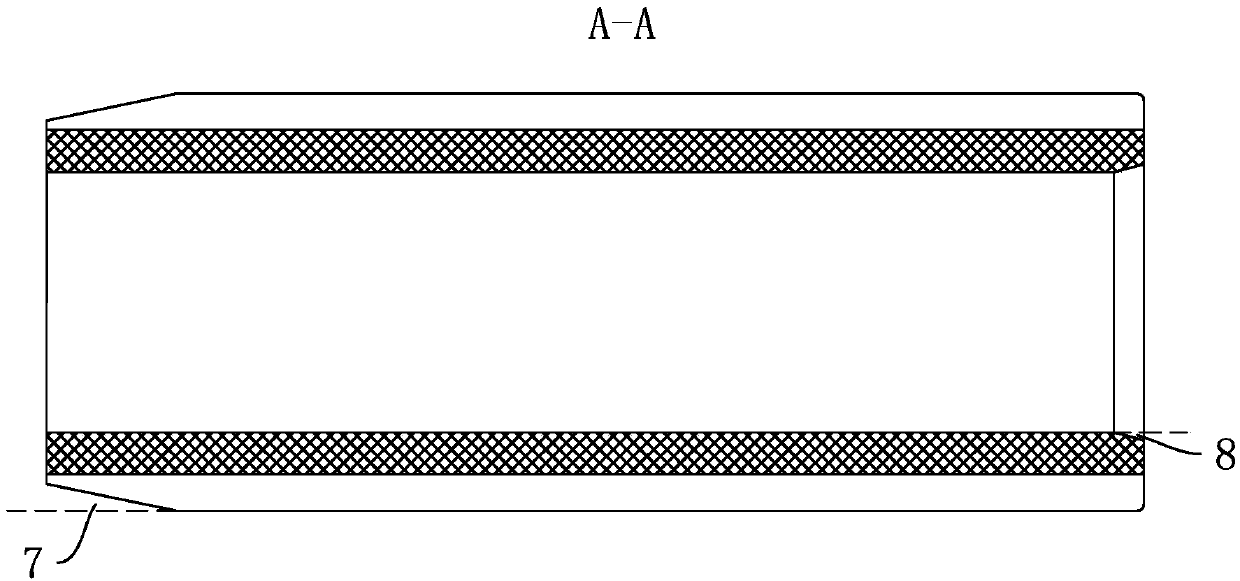

[0033] Such as Figure 1-2 As shown, a rubber sleeve for the mandrel of a cold-rolling and coiling machine is an integral layered composite structure, from the inside to the outside, there are an oil-resistant inner layer 1, a high resilience middle layer 2 and a cut-off head printing outer layer 3 in sequence. The hardness of the oil-resistant inner layer 1, the high resilience middle layer 2 and the cut-off head printing outer layer 3 is the high resilience middle layer 2> Oil resistant inner layer 1> Cut the outer layer of the leading printing 3.

[0034] The adhesive transition layer 4 is used between the oil-resistant inner layer 1 and the high-resilience middle layer 2, and between the high-resilience middle layer 2 and the outer layer 3 of the cutting head printing. The oil-resistant inner layer 1, the high resilience middle layer 2 and the cut-off head printing outer layer 3 are bonded and vulcanized through the adhesive transition layer 4 to form an integral one-time mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com