Medical hydrocolloid dressing and preparation method thereof

A technology of hydrocolloid and hydrocolloid layer, applied in dressings, viscous dressings, medical science, etc., can solve problems such as unreachable, no anti-adhesion antibacterial effect, and inability to use exudate, so as to avoid secondary damage and prevent scarring The effect of strong proliferation and exudative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The invention provides a kind of preparation method of medical hydrocolloid dressing, comprising:

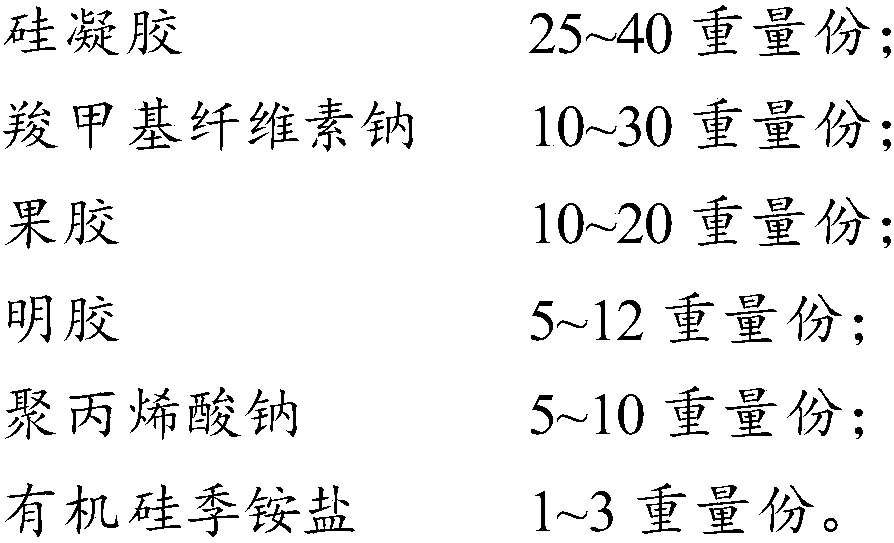

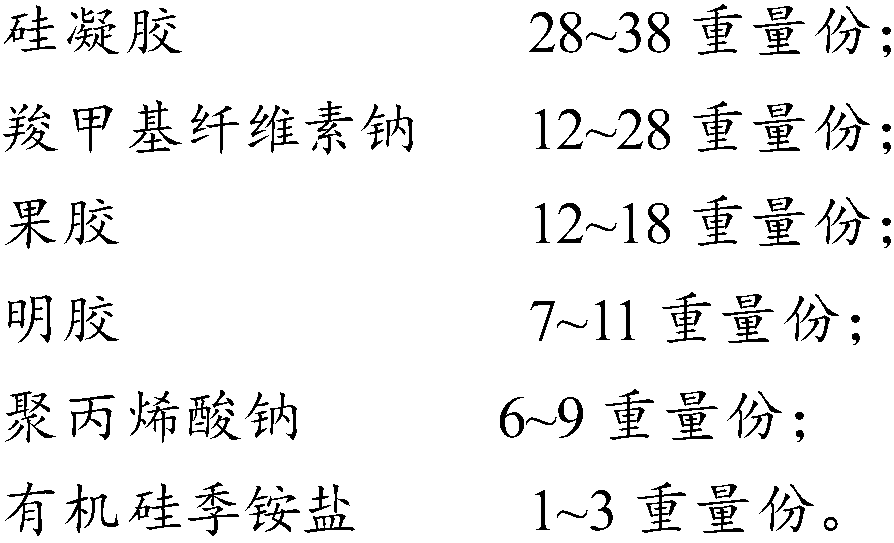

[0060] A) mixing silica gel, sodium carboxymethylcellulose, pectin, gelatin, sodium polyacrylate and organic silicon quaternary ammonium salt, and stirring to obtain a reaction solution;

[0061] B) transferring the reaction solution into a mold provided with a waterproof membrane, solidified to obtain a semi-finished product;

[0062] C) adhering the semi-finished product to a barrier film to obtain a medical hydrocolloid dressing.

[0063] According to the preparation method of the medical hydrocolloid dressing provided by the invention, silica gel, sodium carboxymethyl cellulose, pectin, gelatin, sodium polyacrylate and organic silicon quaternary ammonium salt are mixed and stirred to obtain a reaction solution.

[0064] The silicone gel of the present invention is well known to those skilled in the art, and is divided into silicone gel A and silicone gel B. When in u...

Embodiment 1

[0077] A preparation method of medical hydrocolloid dressing, comprising the following steps

[0078] Step A: Cut the silicone mold to the size of the mold, put it into the forming groove mold, which is coated with a layer of Teflon.

[0079] Step B: Mix 15g of silicone gel A and 15g of silicone gel B, and stir for 5 minutes. After mixing evenly, add 10g of sodium carboxymethylcellulose, 10g of pectin, 5g of gelatin, and 5g of sodium polyacrylate in sequence, and stir After 20 minutes, 1 g of organosilicon quaternary ammonium salt was finally added, and the stirring was continued for 15 minutes. All the stirring was carried out under normal temperature and vacuum.

[0080] Step C: Pour the reaction solution in step B into the mold in step A, let it stand at room temperature for 15 minutes, put it in an oven at 90°C, and let it solidify for 3 hours. After it is completely cured, take out the sample

[0081] Step D: Paste the sticky side of the sample in step C with a barrier f...

Embodiment 2

[0083] Step A: Cut the PU film to the size of the mold, put it into the forming groove mold, where the mold is coated with a layer of Teflon.

[0084] Step B: Mix silicone gel 20gA and silicone gel 18gB, stir for 3 minutes, add 20g sodium carboxymethylcellulose, 15g pectin, 8g gelatin, 8g sodium polyacrylate in sequence after mixing evenly, and stir for 15 minutes, Finally, 2 g of organosilicon quaternary ammonium salts were added, and the stirring was continued for 20 min, and all the stirring was carried out under normal temperature and vacuum.

[0085] Step C: Pour the reaction solution in step B into the mold in step A, let it stand at room temperature for 10 minutes, put it in an oven at 100°C, and let it solidify for 2 hours. After it is completely cured, take out the sample

[0086] Step D: Paste the sticky side of the sample in step C with a barrier film, align with the sample and paste to obtain a medical hydrocolloid dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com