Device and method for hydraulically controlling continuously variable transmission for vehicle

A continuously variable transmission, oil pressure control technology, applied in control devices, vehicle gearboxes, transmissions, etc., can solve problems such as pipeline pressure drop, fuel consumption rate deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

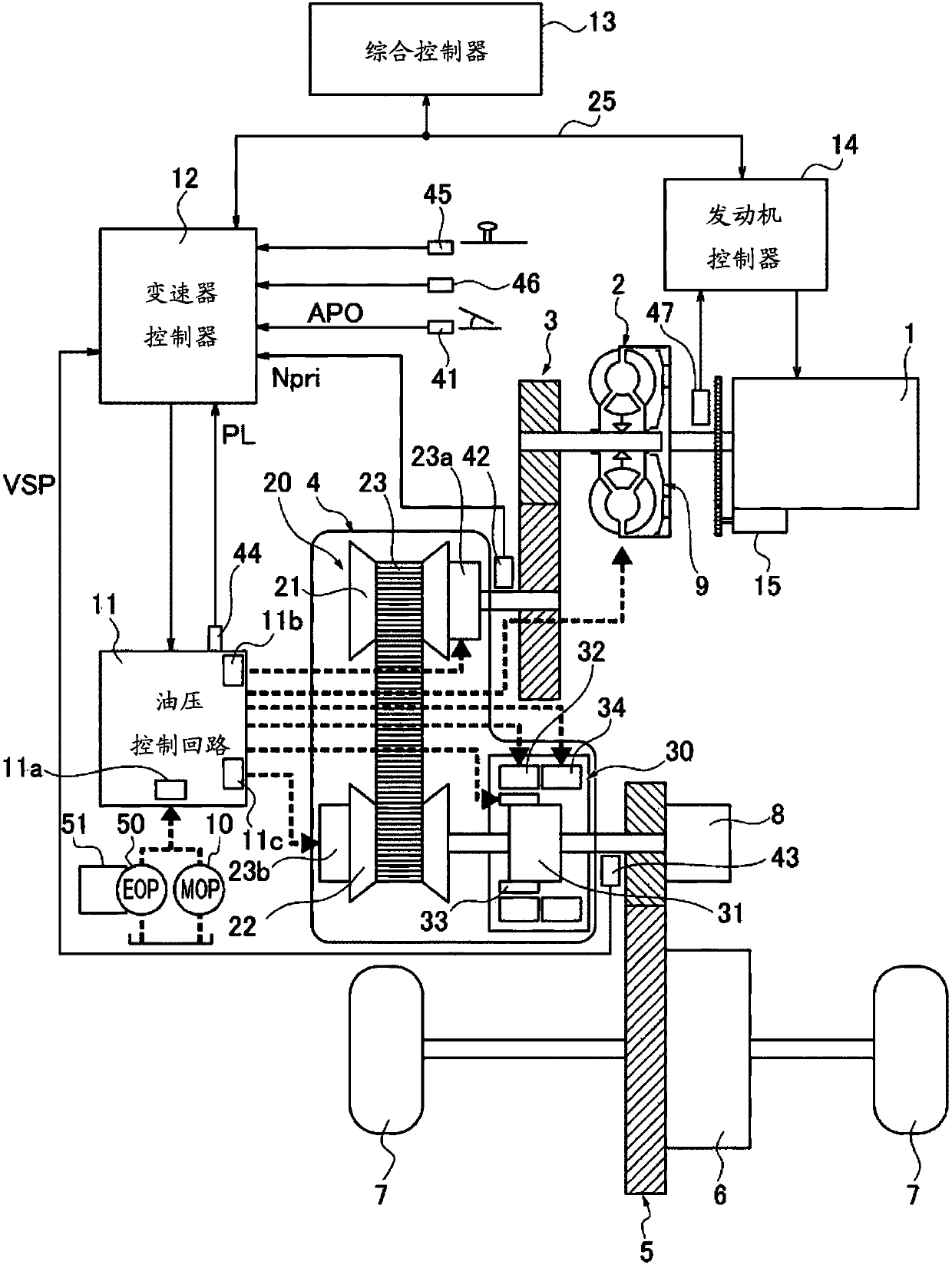

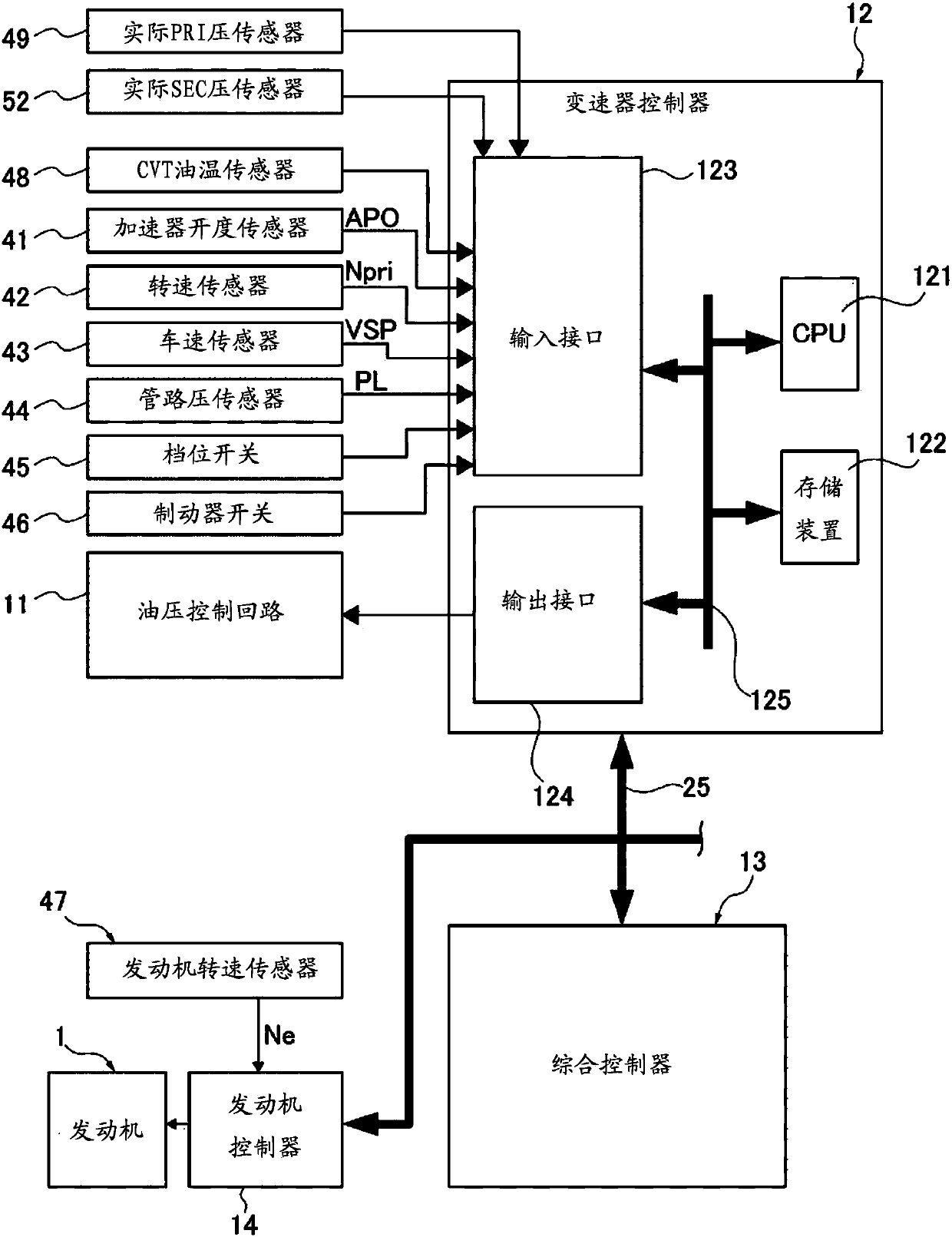

[0029] Hereinafter, the best mode for realizing the hydraulic control device for a continuously variable transmission for a vehicle according to the present invention will be described based on the embodiments shown in the drawings.

[0030] First, the configuration will be described.

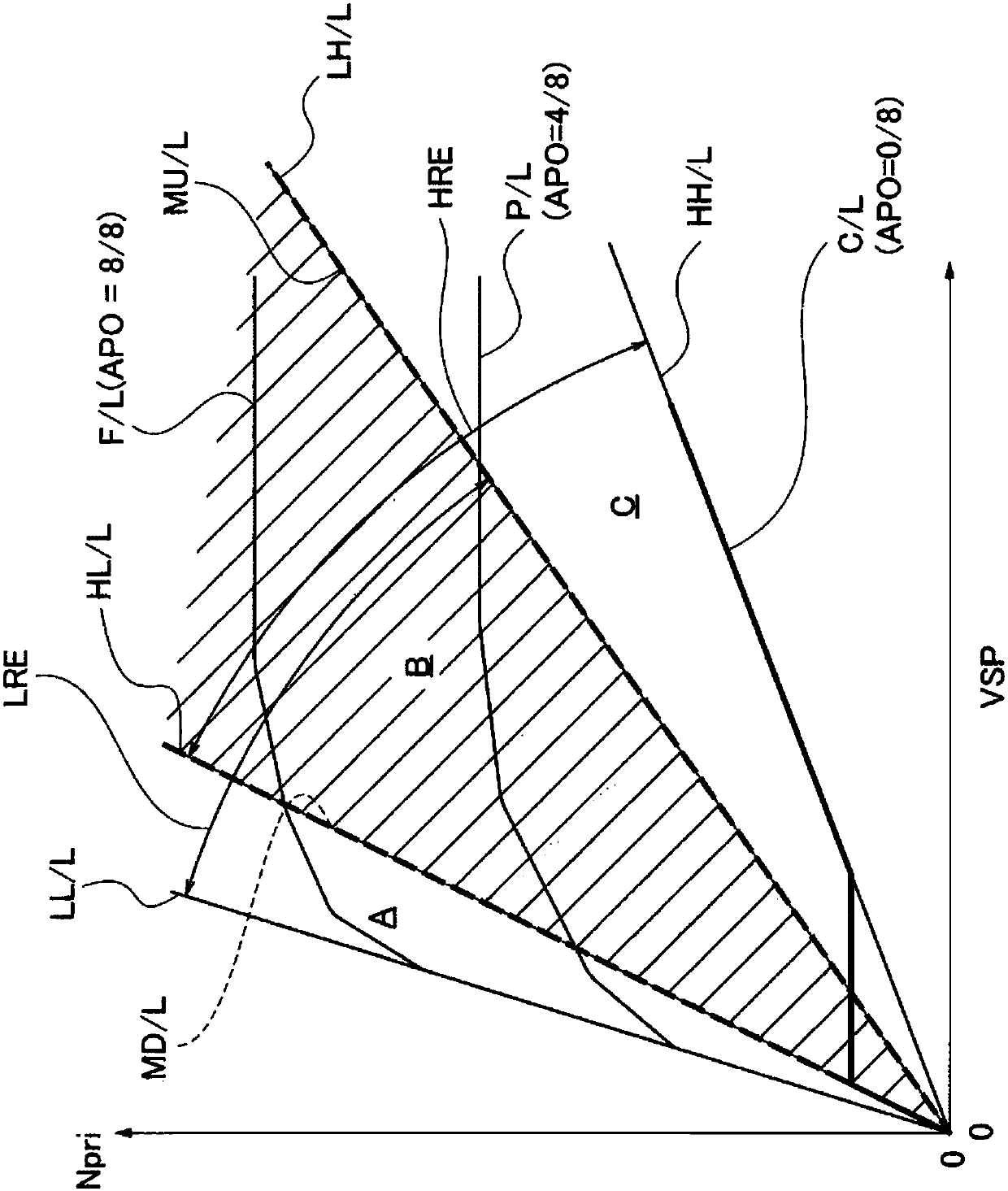

[0031] The hydraulic control device of the embodiment is applied to an engine vehicle equipped with a transmission called a continuously variable transmission with auxiliary transmission. Hereinafter, the configuration of the oil pressure control device of the engine-driven continuously variable transmission in the embodiment is divided into "overall system configuration", "shift control configuration based on shift map", and "line pressure control processing configuration at the time of oil shock detection" Be explained.

[0032] [Overall System Configuration]

[0033] figure 1 Shows the overall configuration of an engine car equipped with a continuously variable transmission with an auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com