Superabsorbent polymer preparation method, and superabsorbent polymer

A superabsorbent, polymer technology, applied in the field of superabsorbent polymers, can solve the problems of weakening the internal cross-linked structure, reducing the basic absorption properties of superabsorbent polymers, and reducing the physical properties of water-absorbent polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

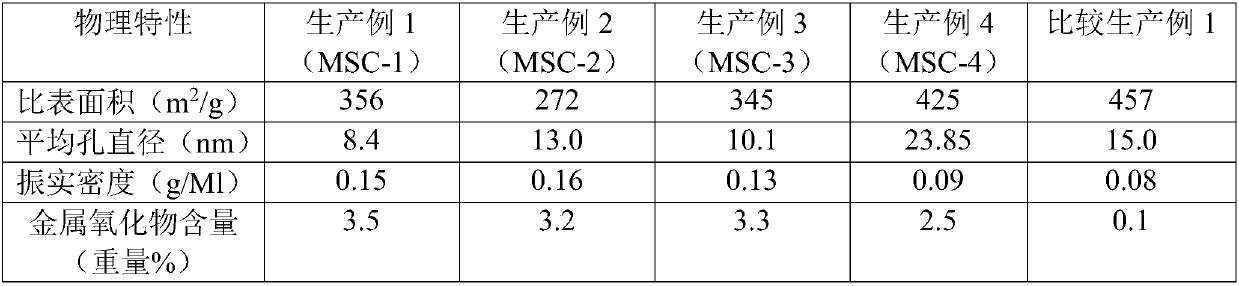

Image

Examples

Embodiment 1

[0139] Example 1: Production of superabsorbent polymer

[0140] Make the composite airgel of 0.1g production example 1 and 1.25g sodium bicarbonate (NaHCO 3 ) mixed to prepare a foaming composition. The foaming composition was mixed with 100 g of acrylic acid, 0.34 g of polyethylene glycol diacrylate (Mw=598) as a crosslinking agent, 121.5 g of 32% caustic soda (NaOH), 0.008 g of diphenyl (2 , 4,6-trimethylbenzoyl)-phosphine oxide, 0.200 g of sodium persulfate, and 36.6 g of water were mixed to produce a monomer composition with a monomer concentration of 47% by weight.

[0141]Subsequently, the monomer composition was introduced through a feeder of a polymerization reactor equipped with a continuously moving conveyor belt. Irradiate ultraviolet rays with ultraviolet irradiation device (irradiation amount 2mW / cm 2 ) for UV polymerization for 2 minutes to produce a hydrogel polymer.

[0142] The hydrogel polymer was transferred to a cutter and cut to 0.2 cm size. At this t...

Embodiment 2

[0144] Example 2: Production of superabsorbent polymer

[0145] A superabsorbent polymer was produced in the same manner as in Example 1 except that a foaming composition containing 1 g of the composite airgel of Production Example 1 and 1 g of sodium bicarbonate was used.

Embodiment 3

[0146] Example 3: Production of superabsorbent polymer

[0147] A superabsorbent polymer was produced in the same manner as in Example 1 except that a foaming composition containing 0.3 g of the composite airgel of Production Example 2 and 1 g of sodium bicarbonate was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com