Material feeding and taking device of tube furnace, tube furnace and gasification method

A technology of tube furnace and feeding material, applied in the direction of furnace, furnace type, furnace components, etc., can solve the problems of material property change, inability to be green and environmentally friendly, toxic exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

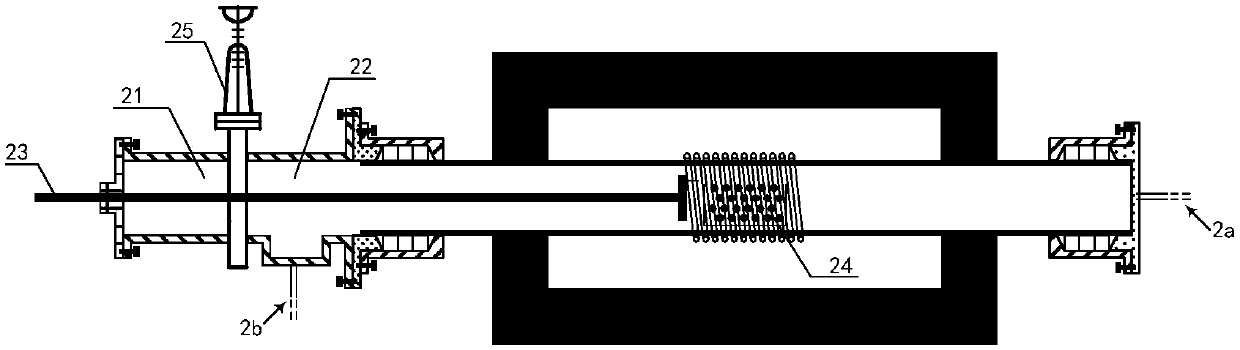

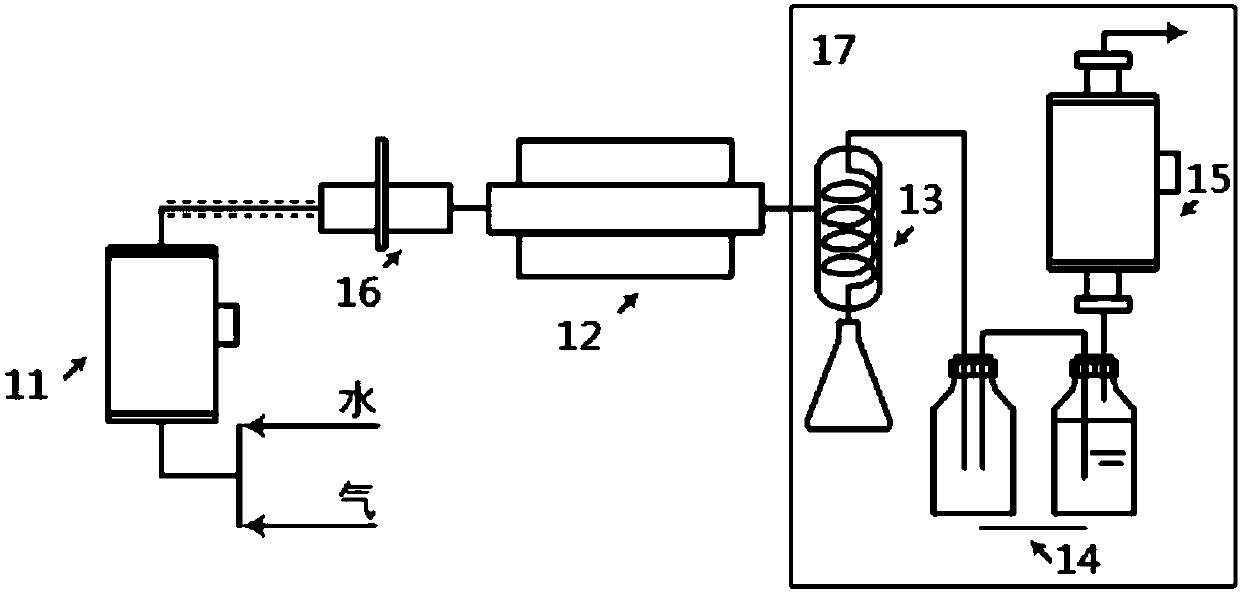

[0073] This embodiment adopts as figure 2 The tube furnace shown is carried out, and the structure of the material feeding and feeding device in the tube furnace is as follows figure 1 As shown, and the material rod of the material feeding and feeding device is as image 3 shown. specifically:

[0074]First, place the silo 24 filled with materials in the material preparation room 21, and at this time the partition 25 is closed; when the tube furnace is heated to the preheating temperature (1600°C), the partition 25 is opened, and the material The bin 24 is pushed into the determined position of the corundum tube furnace body, and then the material rod 23 is drawn back into the material preparation room 21, and the partition 25 is closed.

[0075] Then, feed water and nitrogen (the volume ratio at normal temperature and pressure is 1:40, the same below), water and nitrogen are preheated to 600°C by the water-gas preheating unit 11, and then enter the furnace body from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com