Chemical leakage detection device

A leak detection device and detection device technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of unqualified pipeline materials, leakage, and failure to consider preventive design, etc., to prevent personnel Effects of injury or mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

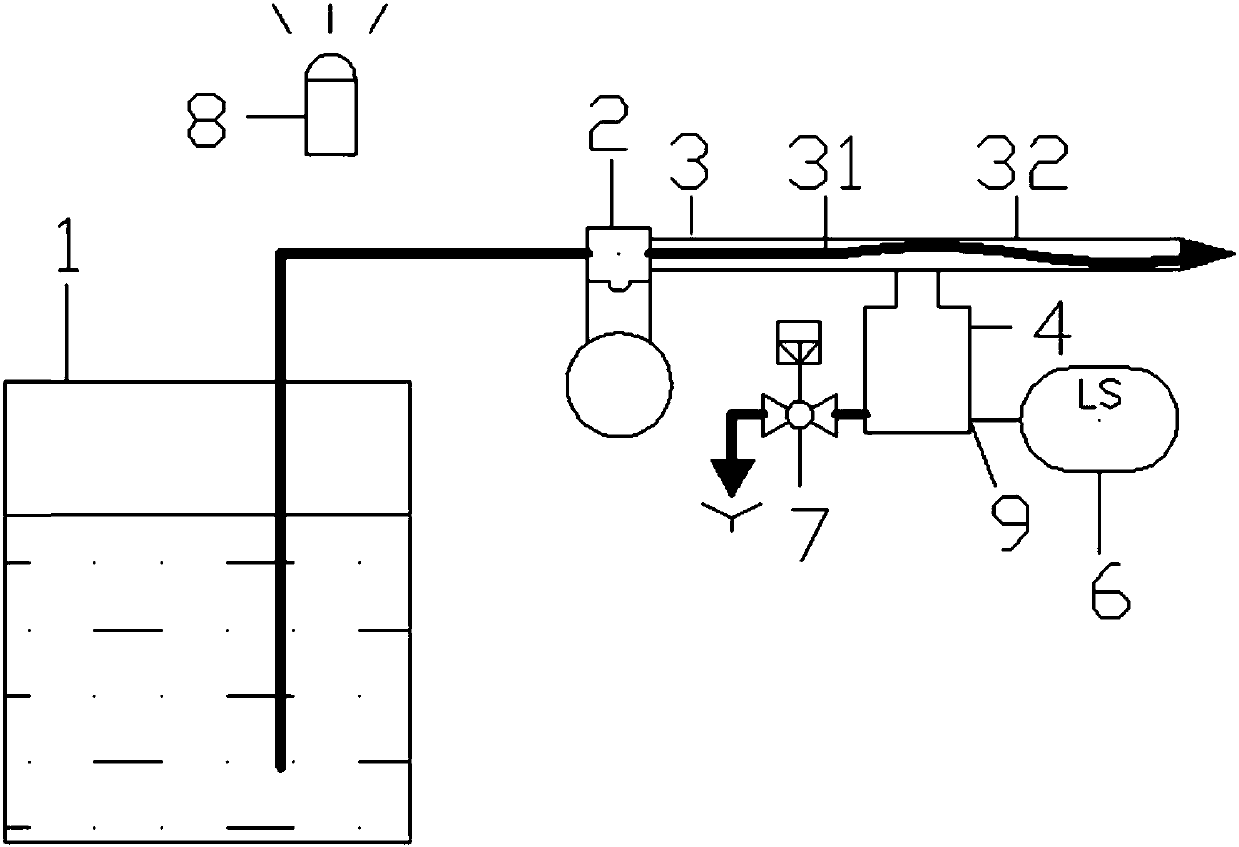

[0042] as attached figure 1 As shown in , the first embodiment of the present invention provides a chemical leakage detection device 100, including a tank 1 for containing chemicals, a pipeline 3 connected to the tank 1 for transporting chemicals, and a 3, the addition pump 2 on the delivery path of 3, the pipeline 3 is also connected with the first leakage collection container 4 for collecting the chemicals leaked from the pipeline 3, the pipeline 3 includes mutually isolated inner tubes 31 and sleeved on the inner tubes The outer outer pipe 32 is the outer pipe 31 , and the chemicals are transported in the inner pipe 31 , and the first leaked liquid collection container 4 communicates with the outer pipe 32 .

[0043] Preferably, the inner tube 31 is made of soft material, and the outer tube 32 is made of hard material. More specifically, the inner tube is made of PVC or PFA hose, and the material of the hose is mainly selected according to the chemical composition. Compare...

no. 2 example

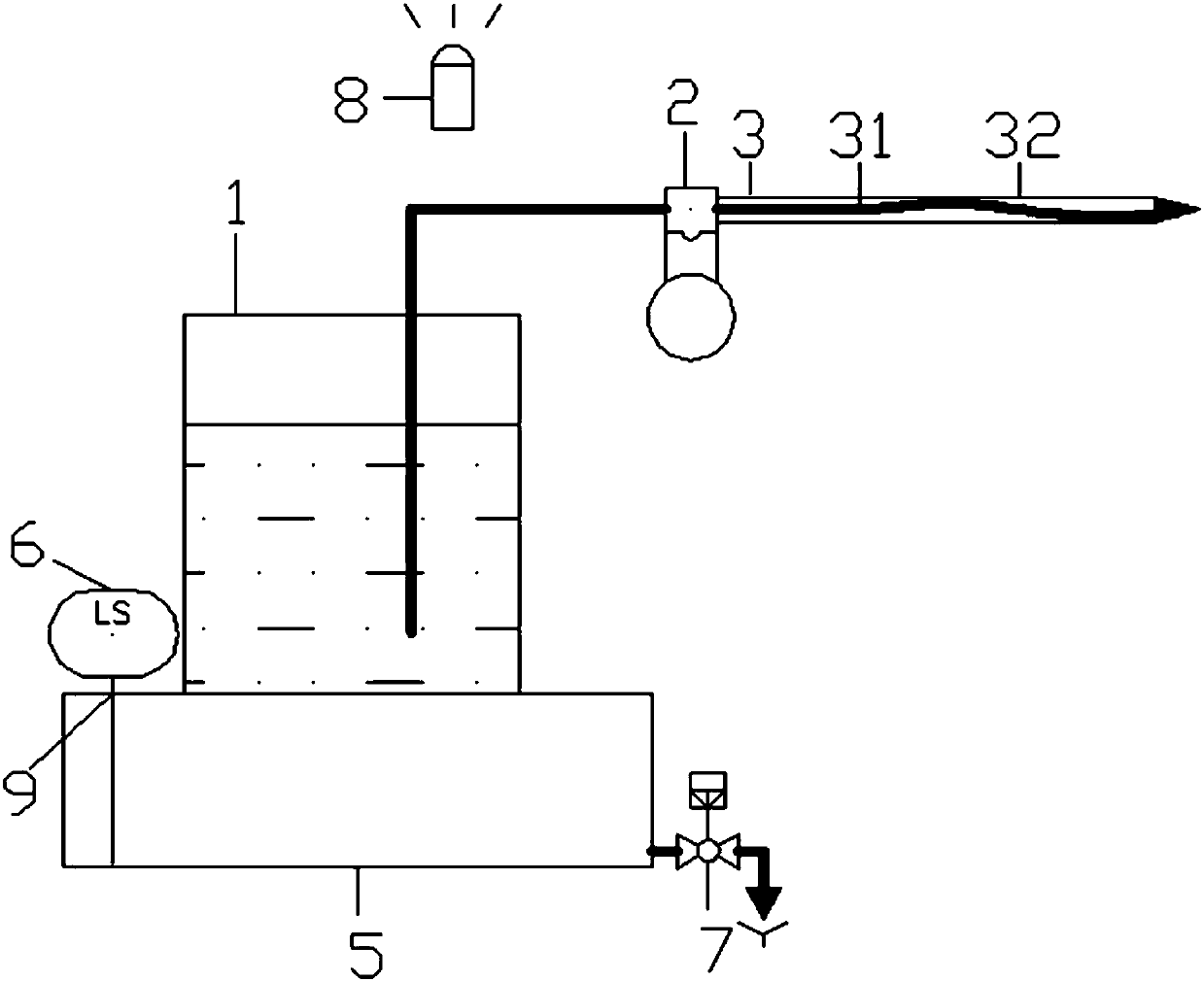

[0051] as attached figure 2 As shown in , the second embodiment of the present invention provides a chemical leakage detection device 100, which includes a barrel 1 for holding chemicals, a pipeline 3 connected to the barrel 1 for transporting chemicals, and a Adding pump 2 on the delivery path of 3, barrel body 1 is connected with the second leakage collection container 5 for collecting chemicals leaked from barrel body 1, and pipeline 3 includes mutually isolated inner tubes 31 and sleeved on the inner side Outer tube 32 on the outside of the tube, chemicals are delivered in inner tube 31 .

[0052] The second leakage collection container 5 of this embodiment is connected to the barrel body 1, which is beneficial to directly intercept and collect the chemicals leaked from the barrel body 1, and avoid personal injury and mechanical damage caused by chemical leakage.

[0053] Preferably, the inner tube 31 is made of soft material, and the outer tube 32 is made of hard materi...

no. 3 example

[0061] as attached image 3 As shown in , the third embodiment of the present invention provides a chemical leakage detection device 100, which includes a barrel 1 for containing chemicals, a pipeline 3 connected to the barrel 1 for transporting chemicals, and a Adding pump 2 on the delivery path of 3, the pipeline 3 is connected with the first leakage collection container 4 for collecting the chemicals leaked from the pipeline 3, and the barrel 1 is connected with the chemical leaking container 4 for collecting the chemicals leaked from the barrel 1. The second liquid leakage collection container 5 of the product, the pipeline 3 includes an inner pipe 31 isolated from each other and an outer pipe 32 sleeved outside the inner pipe, the chemicals are transported in the inner pipe 31, the first liquid leakage collection container 4 is connected to the outer pipe 32 connected.

[0062] Preferably, the inner tube 31 is made of soft material, and the outer tube 32 is made of hard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com