Amine curing agent for seam beauty agent and preparation method thereof and epoxy resin composition for seam beauty agent including amine curing agent

A technology of amine curing agent and epoxy resin, which is applied in the direction of epoxy resin glue, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve problems such as difficult mixing of thixotropic agents, high viscosity of curing agents, and inconvenient downstream construction. , to achieve the effect of simple preparation process, good moisture absorption resistance and convenient gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

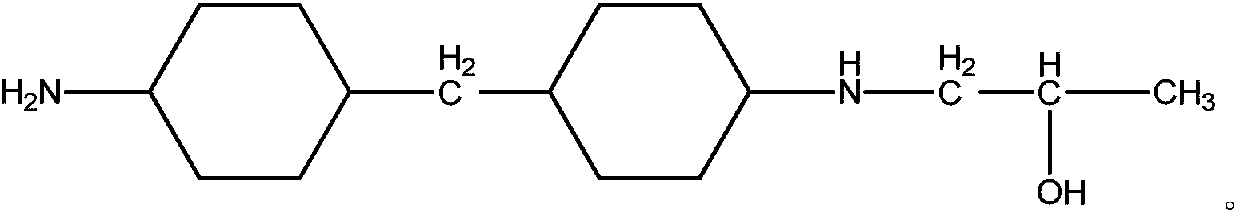

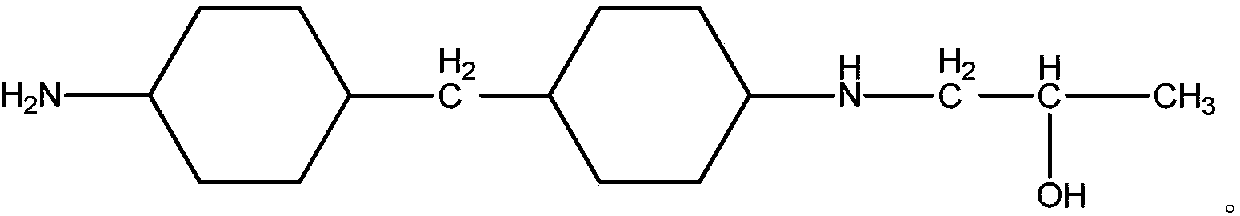

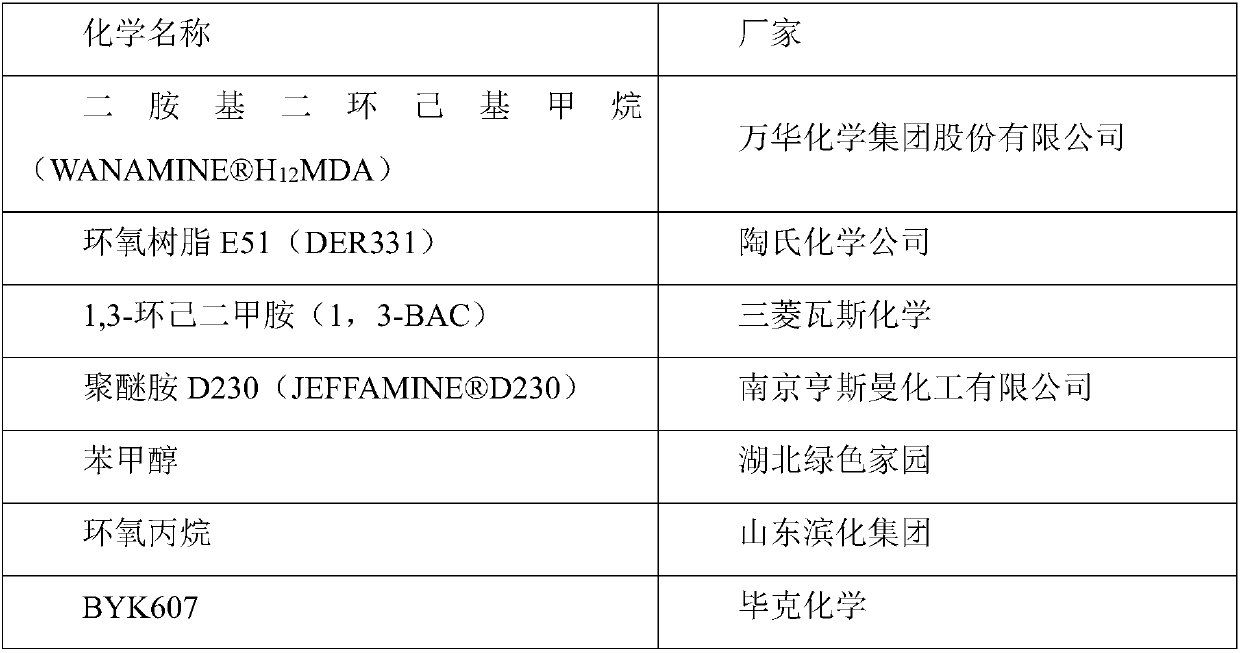

[0062] (1) Preparation of propylene oxide modified diaminodicyclohexylmethane and epoxy curing agent

[0063] 1) Under the protection of nitrogen, control the reaction temperature at 140°C and the reaction pressure at 1MPA, add 0.25 mol of propylene oxide dropwise to 1 mol of HMDA, keep the reaction for 4 hours after the addition is completed, and remove the residual monomers to obtain the ring Propylene oxide modified HMDA.

[0064] 2) Mix 20 parts of modified HMDA, 25 parts of polyetheramine D230, 30 parts of epoxy resin E51, and 25 parts of benzyl alcohol to obtain an epoxy curing agent.

[0065] (2) Preparation of epoxy resin composition

[0066] Preparation of component A: Mix 85g of epoxy resin E51, 10g of diluent benzyl alcohol and 5g of thixotropic agent BYK607, and let stand.

[0067] Preparation of component B: mix 100g of epoxy curing agent with 5g of thixotropic agent BYK607, and let stand.

[0068] After testing, the epoxy curing agent viscosity: 1100cps, surfa...

Embodiment 2

[0070] (1) Preparation of propylene oxide modified diaminodicyclohexylmethane and epoxy curing agent

[0071] 1) Under the protection of nitrogen, control the reaction temperature at 150°C and the reaction pressure at 0.8 MPA, add 0.5 mol of propylene oxide dropwise to 1 mol of HMDA, keep the reaction for 3 hours after the addition is completed, and remove the residual monomers to obtain Propylene oxide modified HMDA.

[0072] 2) Mix 22 parts of modified HMDA, 20 parts of polyetheramine D230, 25 parts of epoxy resin E51, and 30 parts of benzyl alcohol to obtain an epoxy curing agent.

[0073] (2) Preparation of epoxy resin composition

[0074] Preparation of component A: Mix 90g of epoxy resin E51, 5g of diluent benzyl alcohol and 5g of thixotropic agent BYK607, and let stand.

[0075] Preparation of component B: Mix 100g of epoxy curing agent and 10g of thixotropic agent BYK607 evenly, and let stand.

[0076] After testing, the epoxy curing agent viscosity: 1250cps, surfac...

Embodiment 3

[0078] (1) Preparation of propylene oxide modified diaminodicyclohexylmethane and epoxy curing agent

[0079] 1) Under the protection of nitrogen, control the reaction temperature at 160°C and the reaction pressure at 0.8MPA, add 0.75mol of propylene oxide dropwise to 1mol of HMDA, keep the reaction for 3.5h after the addition is completed, and remove the residual monomers. Propylene oxide modified HMDA was obtained.

[0080] 2) Mix 20 parts of modified HMDA, 30 parts of polyetheramine D230, 30 parts of epoxy resin E51, and 20 parts of benzyl alcohol to obtain an epoxy curing agent.

[0081] (2) Preparation of epoxy resin composition

[0082] Preparation of component A: Mix 90g of epoxy resin E51, 5g of diluent benzyl alcohol and 5g of thixotropic agent BYK607, and let stand.

[0083] Preparation of component B: Mix 100g of epoxy curing agent and 10g of thixotropic agent BYK607 evenly, and let stand.

[0084] After testing, the viscosity of the epoxy curing agent: 2200cps, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com