Wear-resistant inflatable swimming pool

A technology for swimming pools and fumed white carbon black, applied in the field of polymer materials, can solve the problems affecting the appearance and service life of inflatable swimming pools, swimming pool bumps and frictions, health hazards of consumers, etc., to increase thickness, avoid falls and wear strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

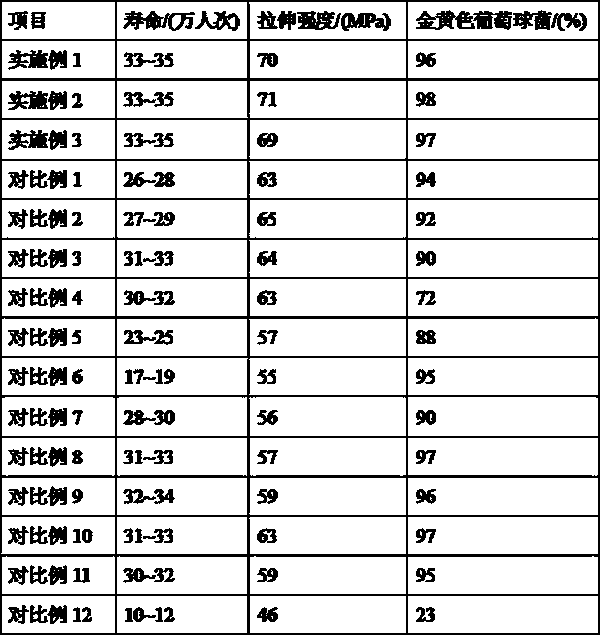

Examples

Embodiment 1

[0018] A wear-resistant inflatable swimming pool, made of the following raw materials in parts by weight: PVC resin 120, chlorinated paraffin 2, fumed white carbon black 1, nano-titanium dioxide 1, zinc oxide 1, antibacterial sepiolite 1, stabilizer 0.7, poly Methyl methacrylate 0.7, aminophylline 0.3.

[0019] The fumed white carbon black is hydrophobic fumed white carbon black.

[0020] For the antibacterial sepiolite, after mixing nano-silver and sepiolite powder, add water in an amount 90 times the weight of sepiolite powder, heat and boil until there is no obvious moisture, then place it at 800°C for 15 minutes and then cool it down to 400°C. After keeping warm for 30 minutes, take it out and crush it to 60~70nm to get antibacterial sepiolite.

[0021] Described nanometer silver, weight is 10% of sepiolite weight.

[0022] Described stabilizer is graphene.

[0023] A method for preparing a wear-resistant inflatable swimming pool, comprising the following steps:

[002...

Embodiment 2

[0029] A wear-resistant inflatable swimming pool is made of the following raw materials in parts by weight: PVC resin 125, chlorinated paraffin 2.5, fumed white carbon black 1.5, nano titanium dioxide 1.5, zinc oxide 1.5, antibacterial sepiolite 1.5, stabilizer 0.8, poly Methyl methacrylate 0.8, aminophylline 0.4.

[0030] The fumed white carbon black is hydrophobic fumed white carbon black.

[0031] For the antibacterial sepiolite, after mixing nano-silver and sepiolite powder, add water 95 times the weight of sepiolite powder, heat and boil until there is no obvious moisture, then place it at 850°C for 18 minutes, and cool it down to 450°C. After keeping warm for 35 minutes, take it out and crush it to 60~70nm to get antibacterial sepiolite.

[0032] Described nanometer silver, weight is 11% of sepiolite weight.

[0033] Described stabilizer is graphene.

[0034] A method for preparing a wear-resistant inflatable swimming pool, comprising the following steps:

[0035] (1...

Embodiment 3

[0040] A wear-resistant inflatable swimming pool, made of the following raw materials in parts by weight: PVC resin 130, chlorinated paraffin 3, fumed white carbon black 2, nano titanium dioxide 2, zinc oxide 2, antibacterial sepiolite 2, stabilizer 0.9, poly Methyl methacrylate 0.9, aminophylline 0.5.

[0041] The fumed white carbon black is hydrophobic fumed white carbon black.

[0042] For the antibacterial sepiolite, after mixing nano-silver and sepiolite powder, add water 100 times the weight of sepiolite powder, heat and boil until there is no obvious moisture, then place it at 900 ° C for 20 minutes, and cool it down to 500 ° C. After keeping warm for 40 minutes, take it out and crush it to 60~70nm to get antibacterial sepiolite.

[0043] Described nano silver, weight is 12% of sepiolite weight.

[0044] Described stabilizer is graphene.

[0045] A method for preparing a wear-resistant inflatable swimming pool, comprising the following steps:

[0046] (1) Mix PVC re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com