Method for simultaneously reducing municipal sludge and producing hydrogen, and municipal sludge treatment device

A municipal sludge and sludge technology, which is applied in the direction of electrochemical sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of low resource utilization efficiency, cumbersome production process, limited treatment capacity, etc. , achieve high sludge digestion and hydrogen production efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The sludge used in this example is excess sludge from municipal sewage treatment plants. After dehydration and drying, the volatile solid content is 15703 mg / L, accounting for 74% of the total sludge (dry basis).

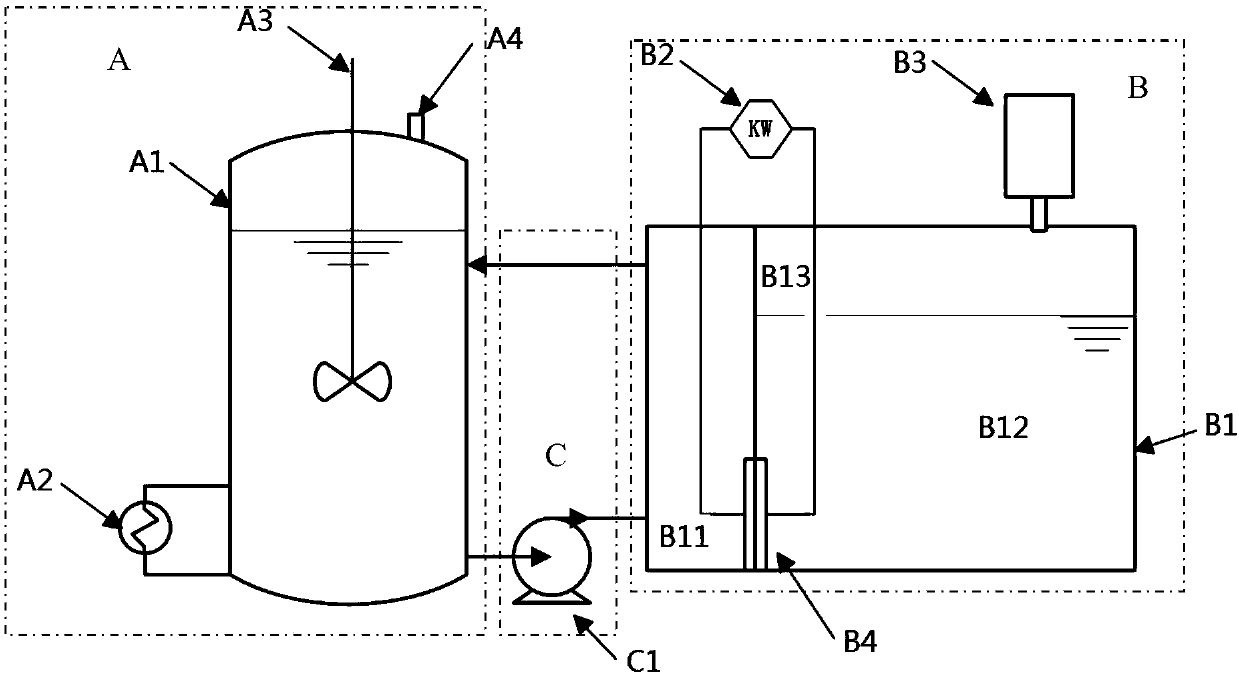

[0075] This embodiment adopts figure 1 The device shown is processed according to the following process, wherein the volume of the mixing pool and the cathode pool are both 500mL, the volume of the anode pool is 50mL, the catholyte used in the cathode pool is 1mol / L phosphoric acid aqueous solution, and the anode is a carbon cloth electrode , the cathode is a platinum carbon electrode (the content of platinum is 0.5mg / cm 2 ).

[0076] Pass water into the mixing tank, then add phosphomolybdic acid, start the stirring paddle for stirring, dissolve phosphomolybdic acid in water to form an aqueous solution with a concentration of 0.3mol / L. The temperature of this aqueous solution was heated to 80°C. Then, with stirring, excess sludge was added to the mixing ta...

Embodiment 2

[0088] The remaining sludge is treated in the same way as in Example 1, the difference is that during the electrolysis process, the voltage of the applied direct current is adjusted to control the current density to 0.1A / cm 2 .

[0089] The experimental results are listed in Table 1.

Embodiment 3

[0091] The remaining sludge is treated in the same way as in Example 1. The difference is that during the electrolysis process, the voltage of the applied direct current is adjusted to control the current density to 0.05A / cm 2 .

[0092] The experimental results are listed in Table 1.

[0093] Table 1

[0094] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com