PVC synthetic leather for automotive interior

A technology for automotive interior and synthetic leather, applied in the field of leather, can solve the problems of poor anti-aging performance, can not be used as automotive interior material, poor wear resistance of PVC, achieve good wear resistance and scratch resistance, and improve anti-ultraviolet performance. , Improve the effect of anti-aging function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

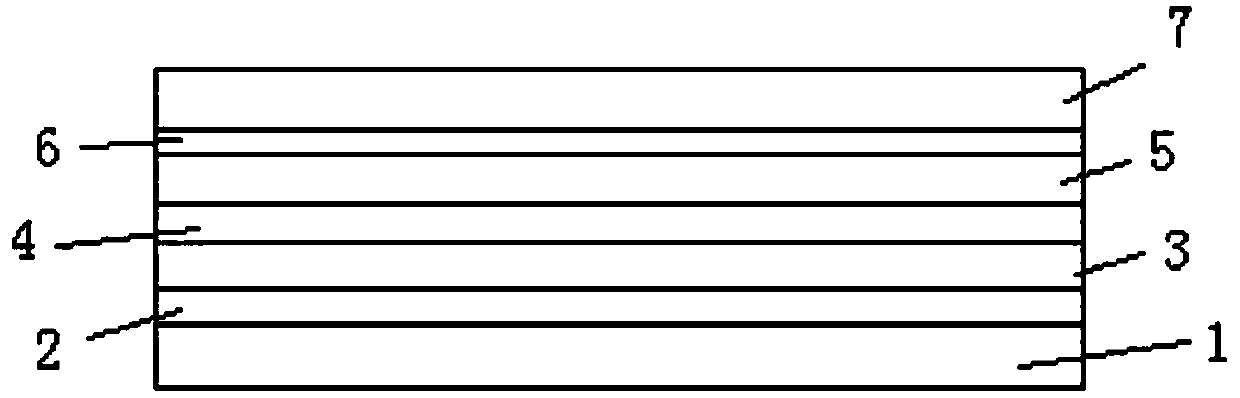

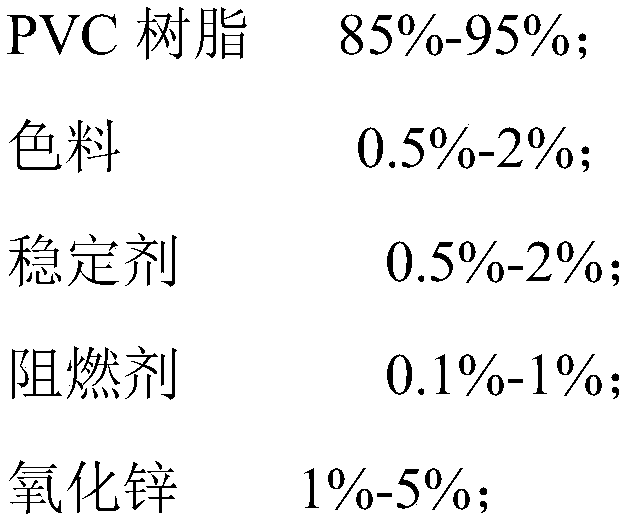

[0033] like figure 1 As shown in the figure, the present invention provides a kind of PVC synthetic leather for automobile interior, which is characterized in that: from bottom to top, the structure of the PVC synthetic leather sequentially includes a PVC base layer 1, a first adhesive layer 2, an antibacterial layer 3, a second adhesive layer The composite layer 4, the anti-ultraviolet layer 5, the third adhesive layer 6 and the wear-resistant layer 7, by weight, the antibacterial layer 3 includes the following components:

[0034] PVC resin 92.5%;

[0035] Chitosan 4%;

[0036] Nano silver antibacterial agent 3.5%;

[0037] The degree of deacetylation of chitosan is 90%, and the molecular weight of chitosan is 150,000.

[0038] By weight, the composition of nano-silver antibacterial agent is:

[0039] 42 nuclear alkyne silver cluster compound [Ag 42 {Eu(W 5 O 18 ) 2}( t BuC≡C) 28 Cl 4 ]OH xH 2 O 30%;

[0040] Silver-loaded zeolite 70%.

[0041] In parts by weig...

Embodiment 2

[0050] like figure 1 As shown in the figure, the present invention provides a kind of PVC synthetic leather for automobile interior, which is characterized in that: from bottom to top, the structure of the PVC synthetic leather sequentially includes a PVC base layer 1, a first adhesive layer 2, an antibacterial layer 3, a second adhesive layer The composite layer 4, the anti-ultraviolet layer 5, the third adhesive layer 6 and the wear-resistant layer 7, by weight, the antibacterial layer 3 includes the following components:

[0051] PVC resin 96.5%;

[0052] Chitosan 1%;

[0053] Nano silver antibacterial agent 2.5%;

[0054] The deacetylation degree of the chitosan is 92%, and the molecular weight of the chitosan is 180,000.

[0055]By weight, the composition of the nano-silver antibacterial agent is:

[0056] 42 nuclear alkyne silver cluster compound [Ag 42 {Eu(W 5 O 18 ) 2}( t BuC≡C) 28 Cl 4 ]OH xH 2 O 25%;

[0057] Silver-loaded zeolite 75%.

[0058] In parts...

Embodiment 3

[0068] like figure 1 As shown in the figure, the present invention provides a kind of PVC synthetic leather for automobile interior, which is characterized in that: from bottom to top, the structure of the PVC synthetic leather sequentially includes a PVC base layer 1, a first adhesive layer 2, an antibacterial layer 3, a second adhesive layer The composite layer 4, the anti-ultraviolet layer 5, the third adhesive layer 6 and the wear-resistant layer 7, by weight, the antibacterial layer 3 includes the following components:

[0069] PVC resin 98%;

[0070] Chitosan 1.5%;

[0071] Nano silver antibacterial agent 0.5%;

[0072] The deacetylation degree of the chitosan is 88%, and the molecular weight of the chitosan is 120,000.

[0073] By weight, the composition of the nano-silver antibacterial agent is:

[0074] 42 nuclear alkyne silver cluster compound [Ag 42 {Eu(W 5 O 18 ) 2}( t BuC≡C) 28 Cl 4 ]OH xH 2 O 35%;

[0075] Silver-loaded zeolite 65%.

[0076] In part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com