Fine-tuning drilling device

A technology of drilling equipment and drilling mechanism, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring machine/drilling machine parts, etc. It can solve the problems of waste, unqualified products, and large workpiece processing errors, etc., and achieve Reduce cleaning time, improve processing accuracy, and protect the effect of drill pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

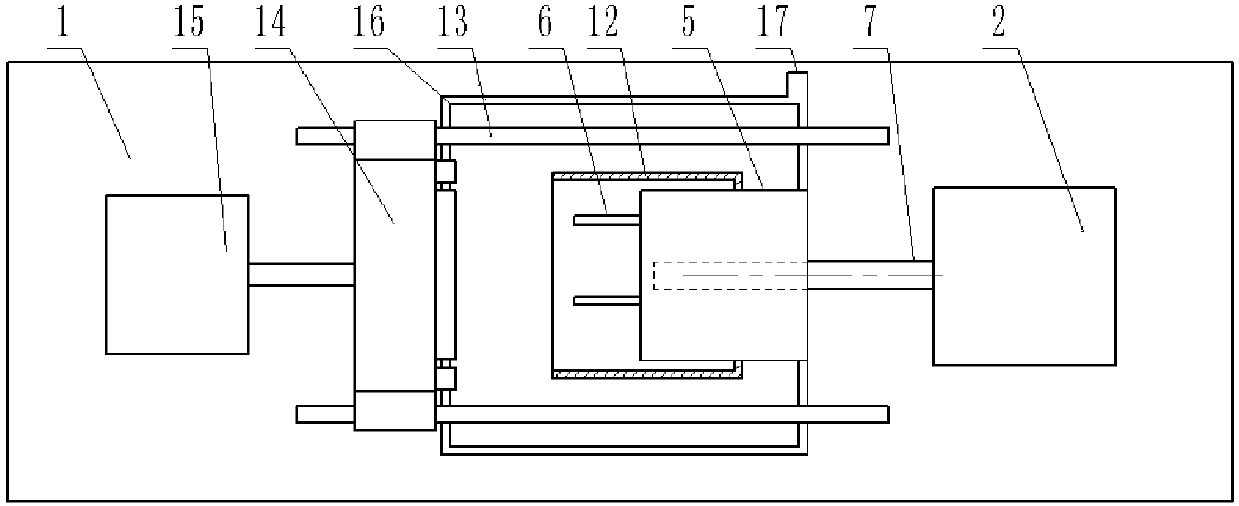

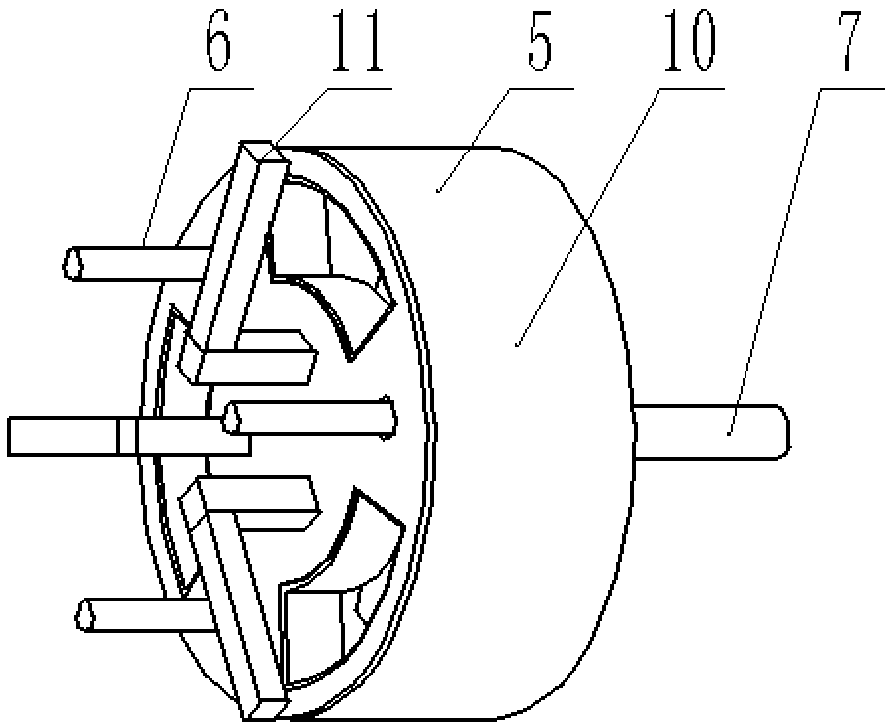

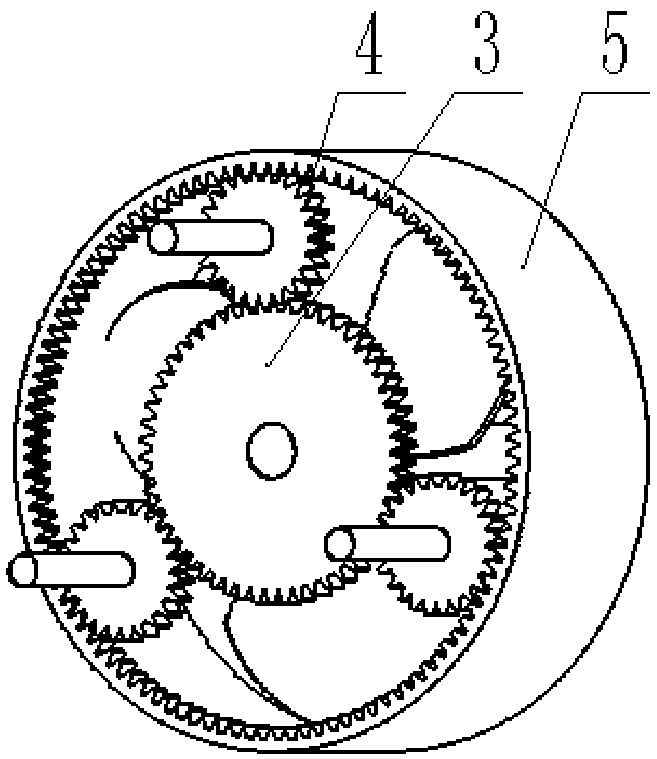

[0019] The reference signs in the drawings of the description include: bracket 1, drilling motor 2, sun gear 3, planetary gear 4, ring gear 5, drill rod 6, output shaft 7, smooth part 8, blade 9, planet carrier 10, L Type rod 11, outer tube 12, slide rail 13, positioning frame 14, cylinder 15, hose 16, chip discharge hole 17, jaw 18.

[0020] Such as Figure 1 to Figure 5 As shown, a finely adjustable drilling device includes a bracket 1, a drilling mechanism and a clamping mechanism. The drilling mechanism comprises the drilling motor 2 at the right end of the mounting bracket 1, and the output shaft 7 of the drilling motor 2 is equipped with 4 series of planetary gears. The planetary gear 4 series includes a sun gear 3 coaxially installed on the free end of the output shaft 7. The sun gear 3 is meshed with three planetary gears 4 evenly distributed in the circumferential direction. The left e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com