Low-temperature low-oxygen preprocessing method for making NFC pear juice

A low-temperature, pear juice technology, applied in food heat treatment, juice extraction, function of food ingredients, etc., can solve problems such as difficulty in meeting consumer sensory requirements, atypical pear juice products, loss of pear aroma, etc. Utilize, improve sensory quality and nutritional value, reduce browning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

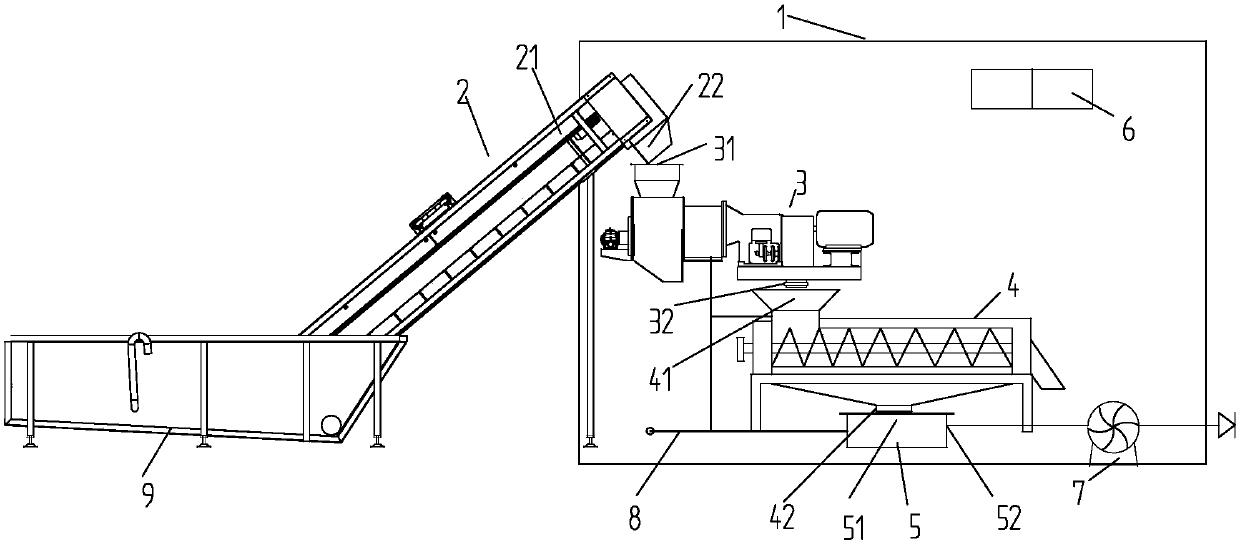

Image

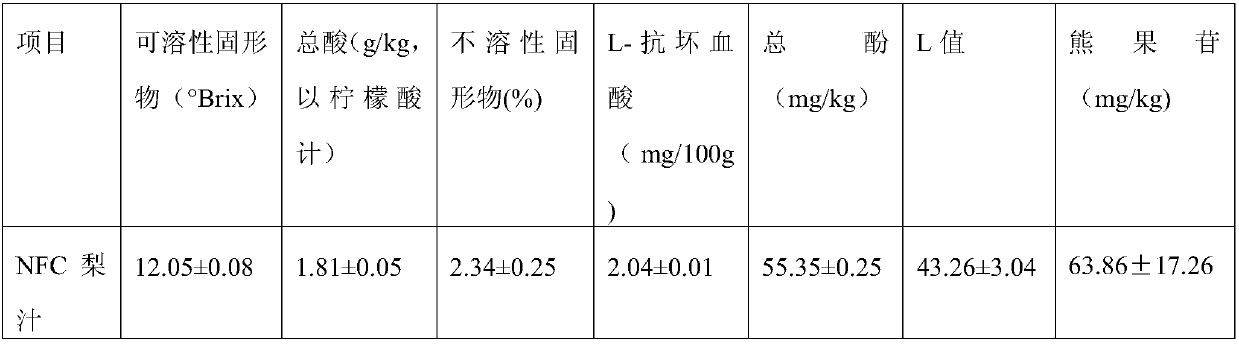

Examples

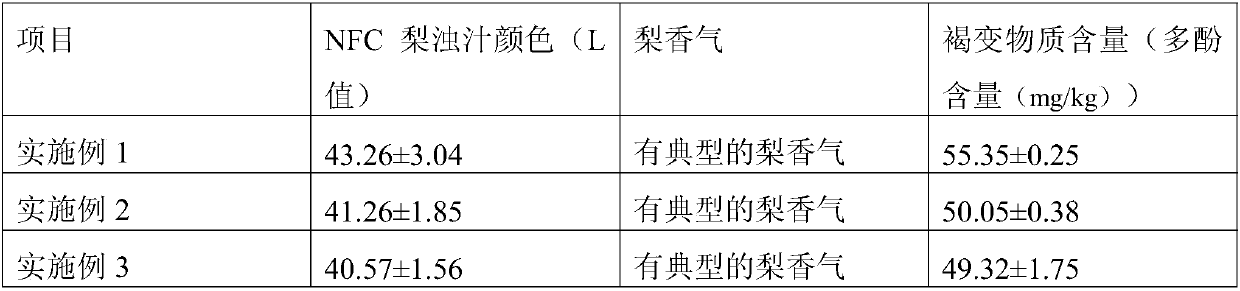

Embodiment 1

[0056] A low-temperature and low-oxygen pretreatment method for producing NFC pear juice, the steps are as follows:

[0057] (1) Raw material cleaning and sorting: take the pear raw materials out of the 4℃ cold storage, use 8℃ low temperature water for bubbling cleaning and spray cleaning, respectively, after cleaning, sorting, and then conveying to the beater through the conveyor belt;

[0058] (2) Low-temperature and low-oxygen cold beating: The beating screen of the beating machine adopts a 1.5mm screen, and the beating machine is placed in a closed room. Before beating, the beating is filled with nitrogen and the air is discharged, and then beating is performed. During the beating process, nitrogen is constantly added. Adjust the nitrogen flow rate so that the dissolved oxygen content in the beating material is 1.3 mg / L, and the ambient temperature is controlled at 6 ℃ by compressed air cooling to reach low temperature conditions, and 1.0‰ VC solution is added during beating to ...

Embodiment 2

[0069] A low-temperature and low-oxygen pretreatment method for producing NFC pear juice, the steps are as follows:

[0070] (1) Raw material cleaning and sorting: take the pear raw materials out of the 4℃ cold storage, use 6℃ low temperature water for bubbling cleaning and spray cleaning, respectively, after cleaning, sorting, and then conveying to the beater through the conveyor belt;

[0071] (2) Low-temperature and low-oxygen cold beating: The beating screen of the beating machine adopts a 1.5mm screen, and the beating machine is placed in a closed room. Before beating, the beating is filled with nitrogen and the air is discharged, and then beating is performed. During the beating process, nitrogen is constantly added. Adjust the nitrogen flow rate so that the dissolved oxygen content in the beating material is 1.8 mg / L, and the ambient temperature is controlled at 7 ℃ through ice water cooling to reach low temperature conditions, and 1.0‰ VC solution is added during beating to ...

Embodiment 3

[0075] A low-temperature and low-oxygen pretreatment method for producing NFC pear juice, the steps are as follows:

[0076] (1) Raw material cleaning and sorting: take the pear raw materials out of the 4℃ cold storage, use 7℃ low temperature water for bubbling cleaning and spray cleaning, respectively, after cleaning, sorting, and then conveying to the beater through the conveyor belt;

[0077] (2) Low-temperature and low-oxygen cold beating: The beating screen of the beating machine adopts a 1.5mm screen, and the beating machine is placed in a closed room. Before beating, the beating is filled with nitrogen and the air is discharged, and then beating is performed. During the beating process, nitrogen is constantly added. Adjust the nitrogen flow rate so that the dissolved oxygen content in the beating material is 2.5mg / L, and cool the environment with ice water to control the ambient temperature at 5℃ to reach low temperature conditions. Add 1.0‰ VC solution during beating to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com