Polysilicon cell plate production line for producing solar cell panels

A technology for solar panels and polysilicon batteries, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve problems such as errors, gluing actions, and poor polishing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

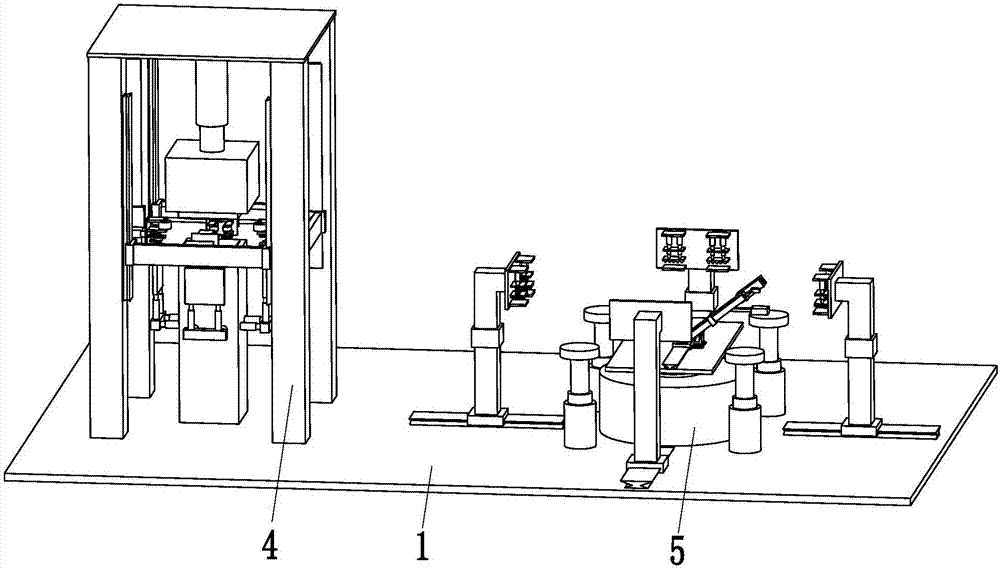

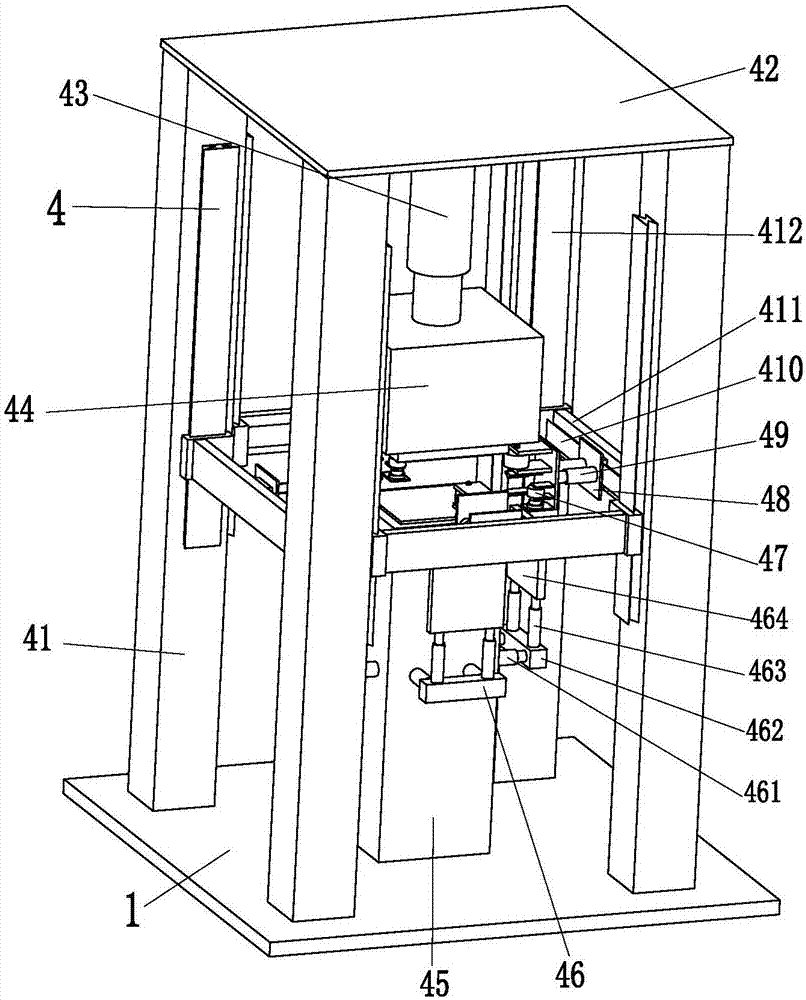

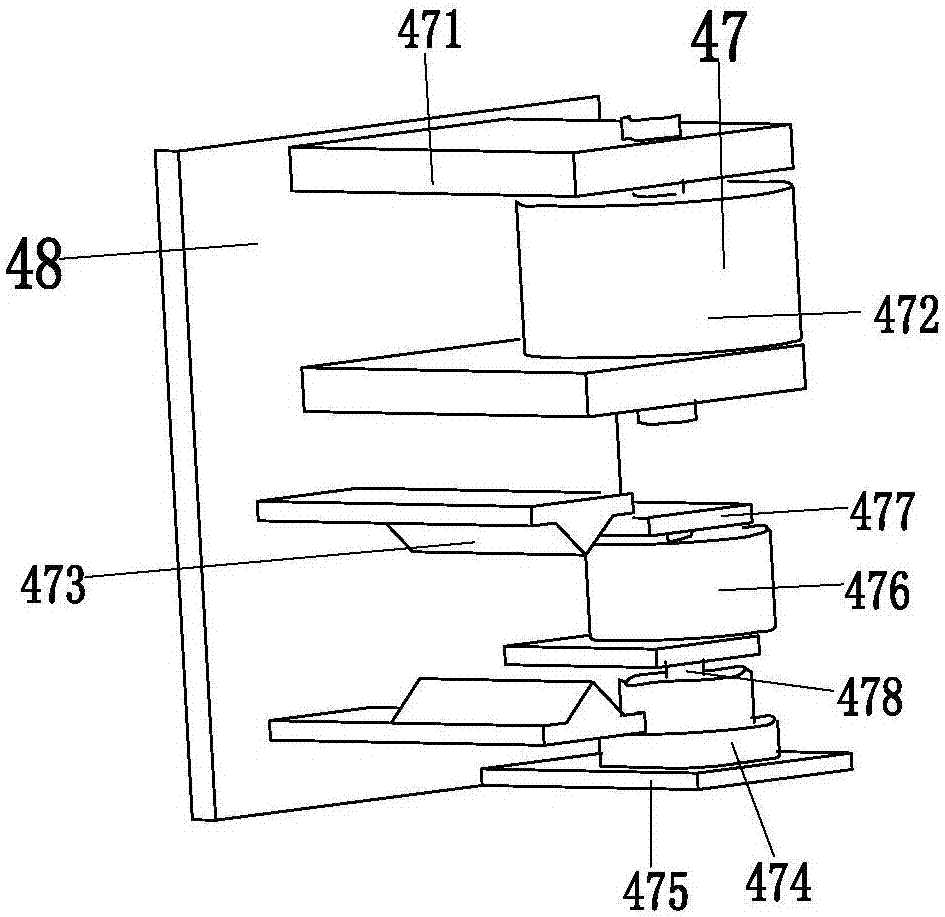

[0027] Such as Figure 1 to Figure 7 As shown, a polysilicon cell processing production line for the production of solar panels includes a support base 1, a polishing device 4, and a frame mounting device 5. The left end of the support base 1 is equipped with a polishing device 4 and a frame mounting device 5 Install on the right end of the support base 1.

[0028] The frame mounting device 5 includes a frame bottom column 51, a frame motor 52, a frame slide groove 53, four frame slide bars 54, a frame connecting plate 55, four frame clamping mechanisms 56, two frame telescopic columns 57, upper f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com