Insulation covering agent of Fe-based soft-magnetic alloyed powder

An insulating coating, soft magnetic metal technology, applied in insulators, inorganic insulators, inorganic materials, etc., can solve the problems of difficulty in forming dense films, affecting the magnetic properties of magnetic powder cores, etc., to improve superposition performance and reduce magnetic loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The sendust metal magnetic powder insulation coating agent is weighed according to the mass composition ratio:

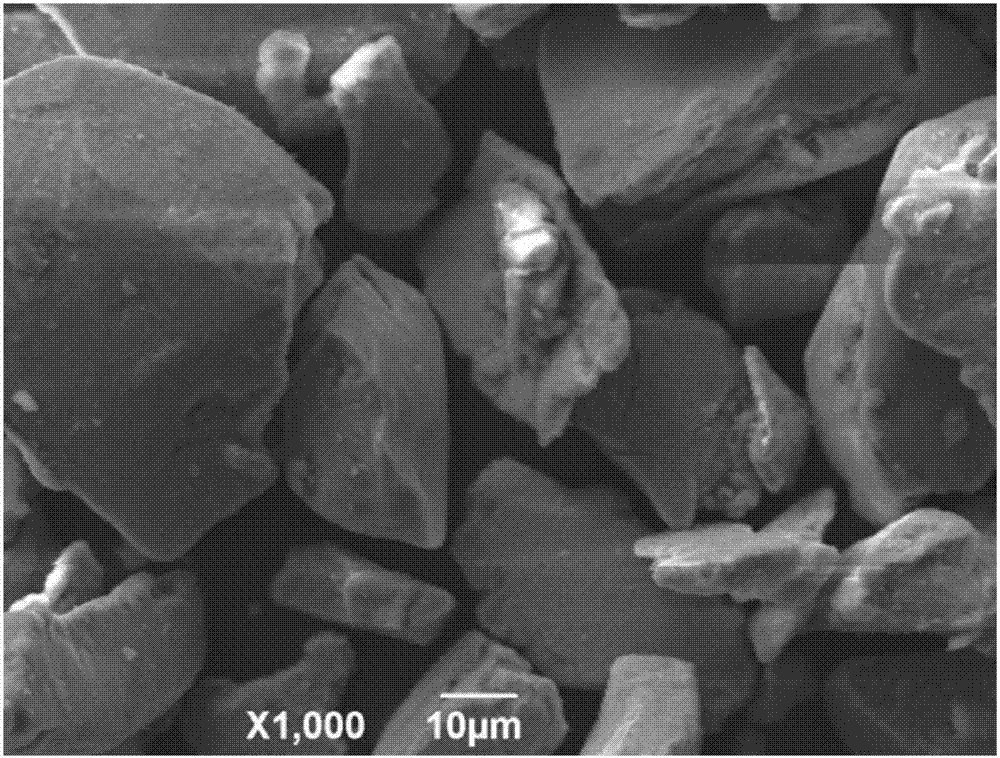

[0020] Phosphoric acid 50wt%; manganese dihydrogen phosphate 10wt%; zinc dihydrogen phosphate 20wt%; sodium tripolyphosphate 18wt%; thiourea 2wt%. Add water to dissolve and mix well. Add the sendust powder into the sendust powder according to the mass ratio of the metal magnetic powder at 2.0%, heat and stir until dry. A dense and insulating sendust metal magnetic powder with a cladding layer is obtained. Such as figure 1 shown.

Embodiment 2

[0022] The sendust metal magnetic powder insulation coating agent is weighed according to the mass composition ratio:

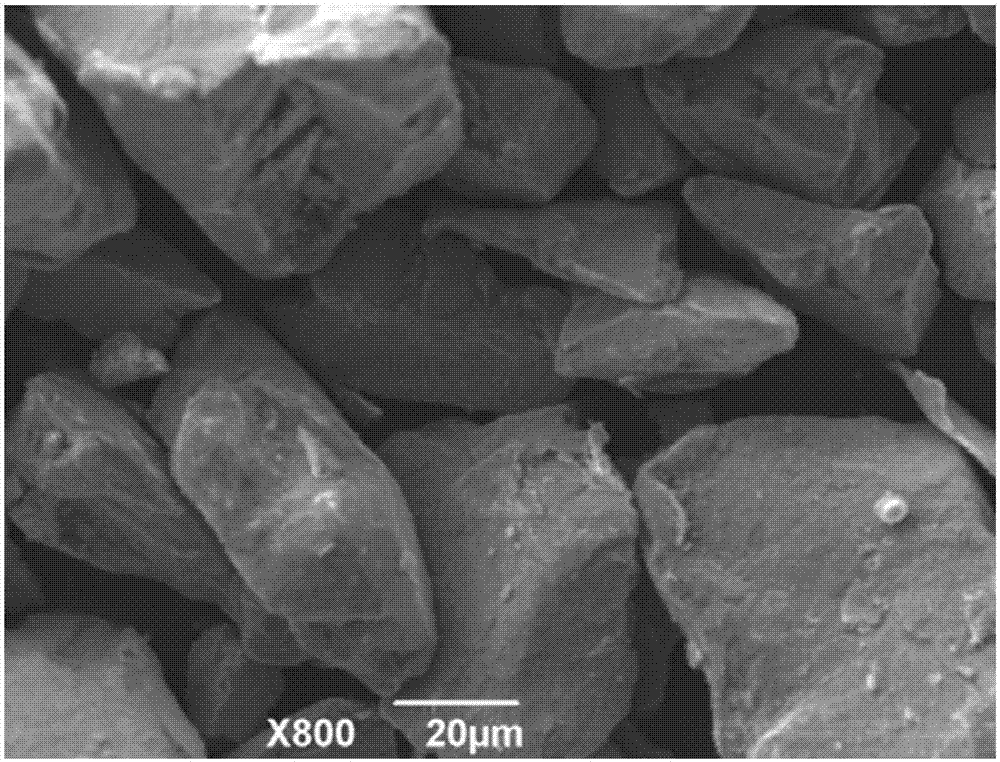

[0023] Phosphoric acid 40wt%; aluminum dihydrogen phosphate 25wt%; zinc dihydrogen phosphate 24wt%; sodium pyrophosphate 10wt%; sodium molybdate 0.5wt%; thiourea 0.5wt%. Add water to dissolve and mix well. The coating agent is added to the sendust powder in an amount of 1.8wt% of the total mass of the metal magnetic powder, heated and stirred until dry. A dense and insulating sendust metal magnetic powder with a cladding layer is obtained. Such as figure 2 shown.

Embodiment 3

[0025] The FeSi metal magnetic powder insulation coating agent is weighed according to the mass composition ratio:

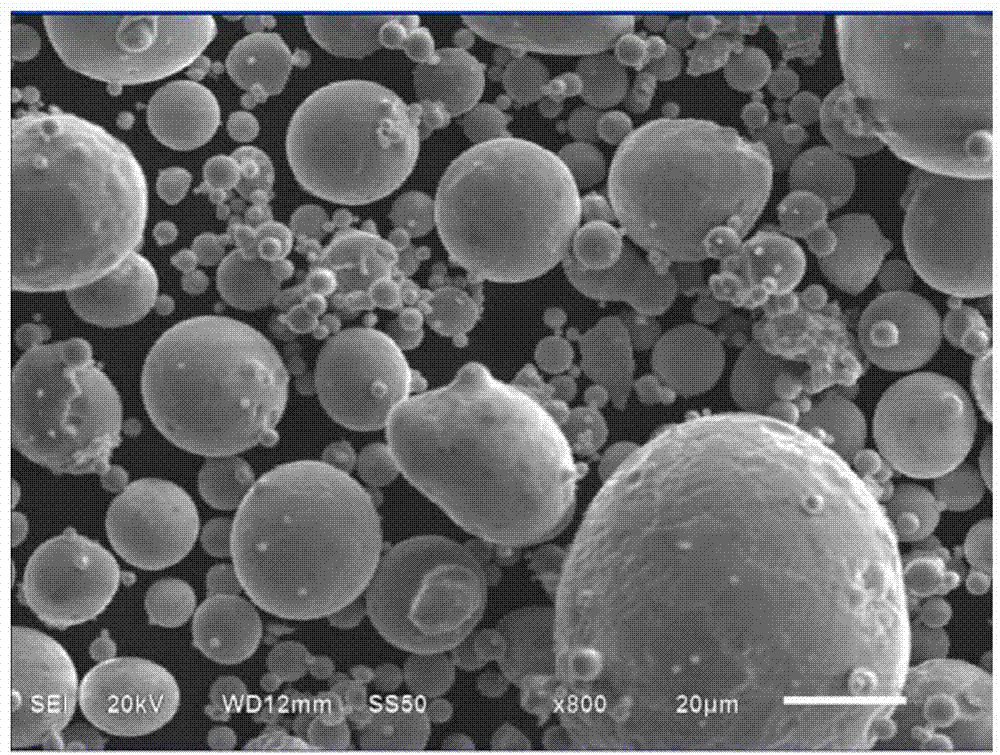

[0026] 10wt% phosphoric acid; 25wt% aluminum dihydrogen phosphate; 30wt% zinc dihydrogen phosphate; 30wt% sodium tripolyphosphate; 1wt% sodium molybdate, 4% hexamethylenetetramine. Add water to dissolve and mix well. The coating agent is added to the iron-silicon powder at a mass ratio of 1.0% of the metal magnetic powder, and heated and stirred until dry. A dense and insulating iron-silicon metal magnetic powder with a cladding layer is obtained. Such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com