Method for simultaneous detection of various volatile organic compounds in marking pen

A technology of volatile organic compounds and marker pens, which is applied in the field of analysis and detection, can solve problems such as reducing detection efficiency, false positive content, and increasing operational complexity, so as to prolong the maintenance cycle and service life of consumables, meet quantitative detection requirements, The effect of reducing the cost of inspection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

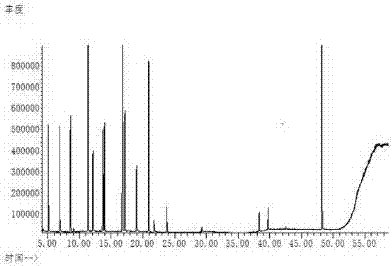

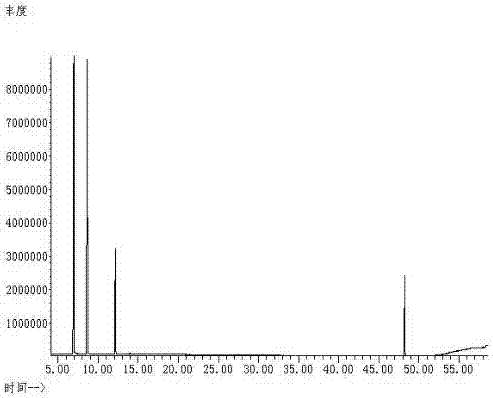

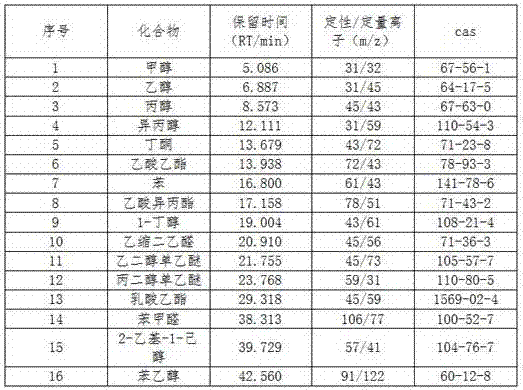

[0027] (1) Detection of volatile organic compound content in marker pen ink

[0028] Take 5ml of analytically pure or above-grade triacetin solution in a 20mL headspace bottle, take a small amount, put the headspace bottle on the weighing pan of the balance and reset it to zero, and disassemble the ink bag of the marker pen, with a total mass of 0.5g. Dilute to volume with the same solvent and cover, then vortex and mix well, and prepare for measurement.

[0029] (2) Working conditions of headspace-gas chromatography mass spectrometer

[0030] a) The headspace furnace temperature is 80°C, equilibrate for 30 minutes, the sampling needle is 110°C, the transfer line temperature is 120°C, the carrier gas is high-purity helium; the headspace carrier gas flow rate is 20ml / min;

[0031] b) The gas chromatography inlet temperature is 120°C; the inlet split ratio is 10:1;

[0032] c) Chromatographic column: 60m×0.25mm×0.25µm capillary column, polyethylene glycol capillary column;

...

Embodiment 2

[0044] (1) Detection of volatile organic compound content in refillable marker pen ink

[0045] Take 5ml of triacetin solution of analytical grade or above in a 20mL headspace bottle, take a small amount, put the headspace bottle on the weighing pan of the balance and reset it to zero, disassemble the marker pen ink bag, with a total mass of 0.2g, Dilute to volume with the same solvent and cover, then vortex and mix well, and prepare for measurement.

[0046] (2) Working conditions of headspace-gas chromatography mass spectrometer

[0047] a) The headspace furnace temperature is 90°C, equilibrated for 40 minutes, the sampling needle is 90°C, the transfer line temperature is 110°C, the carrier gas is high-purity helium; the headspace carrier gas flow rate is 20ml / min;

[0048] b) The gas chromatography inlet temperature is 120°C; the inlet split ratio is 10:1;

[0049] c) Chromatographic column: 60m×0.25mm×0.25µm capillary column, polyethylene glycol capillary column;

[005...

Embodiment 3

[0061] (1) Detection of volatile organic compound content in whiteboard pen ink

[0062] Take 10ml of analytically pure or above-grade glycerol triacetate solution in a 20mL headspace bottle, take a small amount, put the headspace bottle on the weighing pan of the balance and reset it to zero, disassemble the whiteboard pen ink bag, with a total mass of 0.3g, Dilute to volume with the same solvent and cover, then vortex and mix well, and prepare for measurement.

[0063] (2) Working conditions of headspace-gas chromatography mass spectrometer

[0064] a) The headspace furnace temperature is 90°C, equilibrated for 45 minutes, the sampling needle is 100°C, the transfer line temperature is 110°C, the carrier gas is high-purity helium; the headspace carrier gas flow rate is 20ml / min;

[0065] b) The gas chromatography inlet temperature is 120°C; the inlet split ratio is 20:1;

[0066] c) Chromatographic column: 60m×0.25mm×0.25µm capillary column, polyethylene glycol capillary co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com