Device and method for plasma enhanced atomic layer deposition of nickel carbide film

A technique of atomic layer deposition and plasma, which is applied in the fields of electrochemical catalysis and supercapacitors, can solve the problems of less research on thin films, and achieve the effects of low cost, high purity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

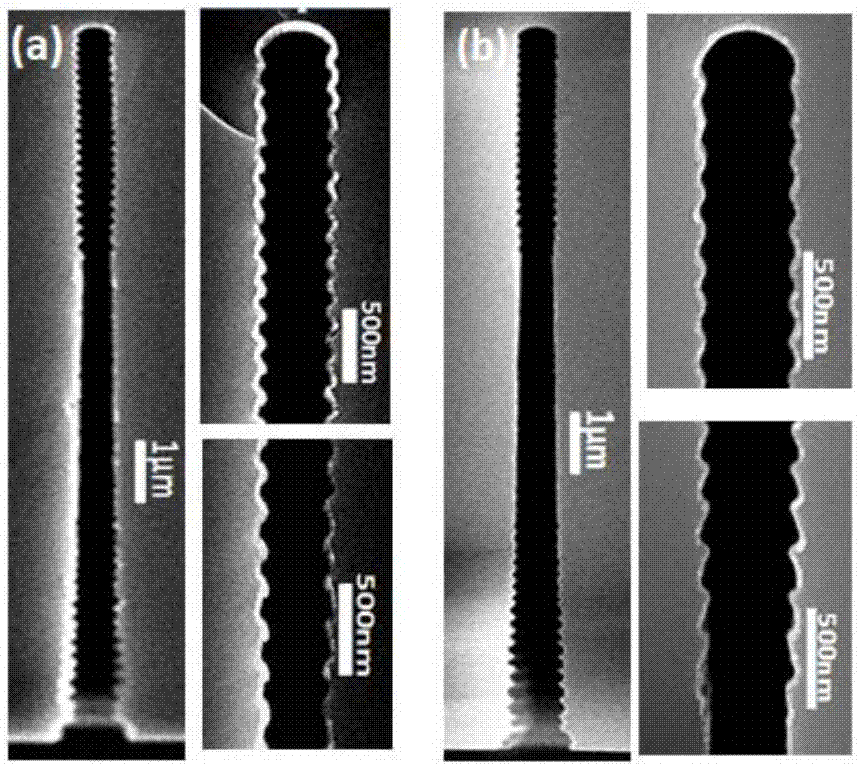

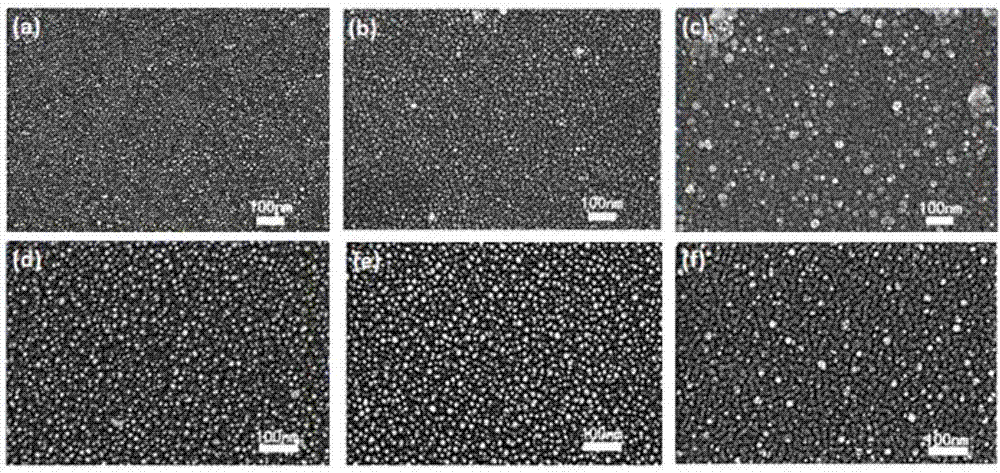

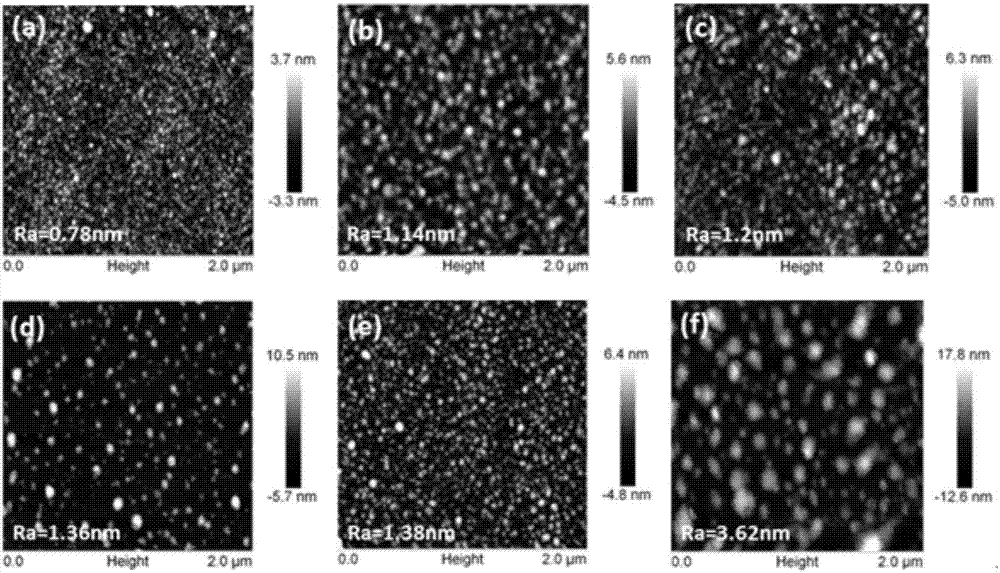

Method used

Image

Examples

Embodiment Construction

[0036]Such as Figure 5 As shown, a device for plasma-enhanced atomic layer deposition of nickel carbide film, including carrier gas bottle 1, hydrogen bottle 2, AMD-Ni monomer bottle 3, DAD-Ni monomer bottle 4, heating furnace 5, mechanical pump 6 and a radio frequency power supply 7, put the AMD-Ni monomer bottle 3 and the DAD-Ni monomer bottle 4 in the heating jacket 8, wrap the heating tape 9 on the inner wall of the heating jacket 8, and be provided with a reaction chamber 10 in the heating furnace 5, A substrate stage is placed in the reaction chamber 10, and a thermocouple is built into the substrate stage. The gas outlets of the carrier gas bottle 1 are respectively connected to a mass flow controller 11, a flow controller 2 12, and a flow controller 3 13. The outlet of controller one 11 is connected to the inlet of ALD valve one 14 and AMD-Ni monomer bottle 3 in turn, and the outlet of flow controller two 12 is connected to the inlet of ALD valve two 15 and DAD-Ni mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com