Hard alloy for soaking plate and soaking plate made of hard alloy

A cemented carbide and vapor chamber technology, applied in the field of cemented carbide, can solve the problems that it is difficult to meet the technical requirements of curved glass, the vapor chamber is difficult to meet the use requirements, and the deformation of stainless steel plate is large, so as to achieve high temperature hardness, Good high temperature oxidation resistance, the effect of eliminating the internal stress of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

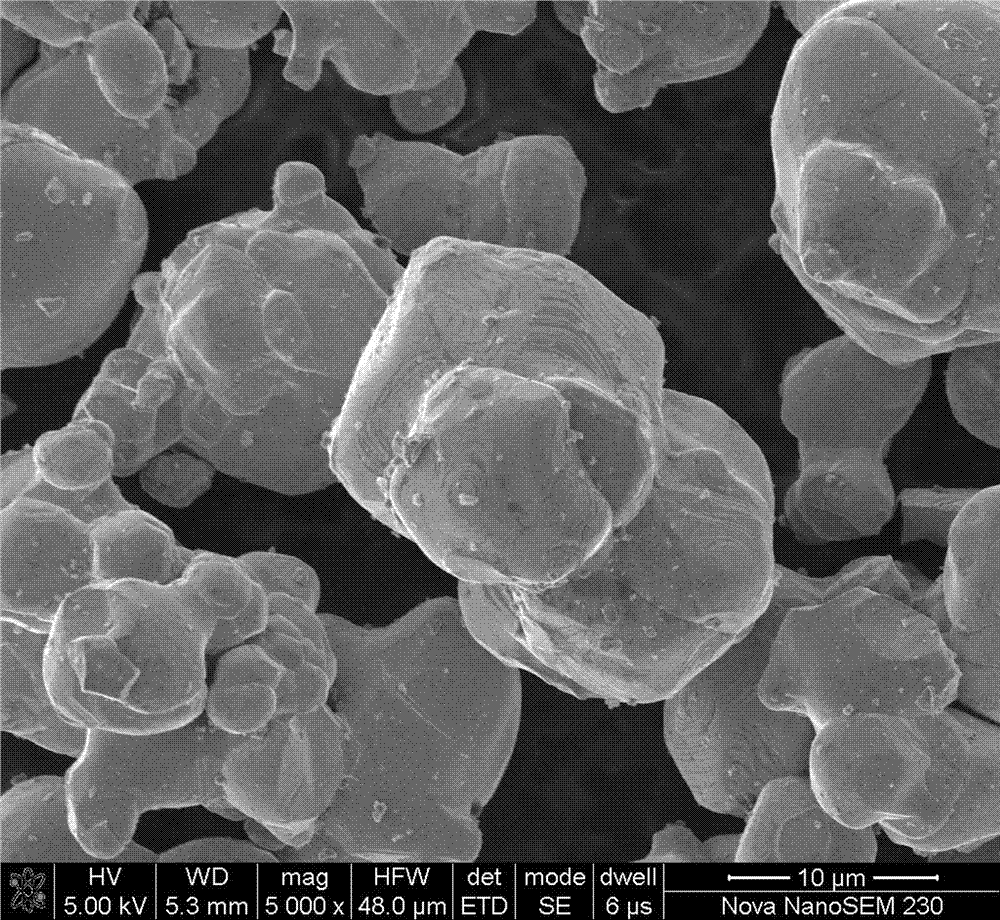

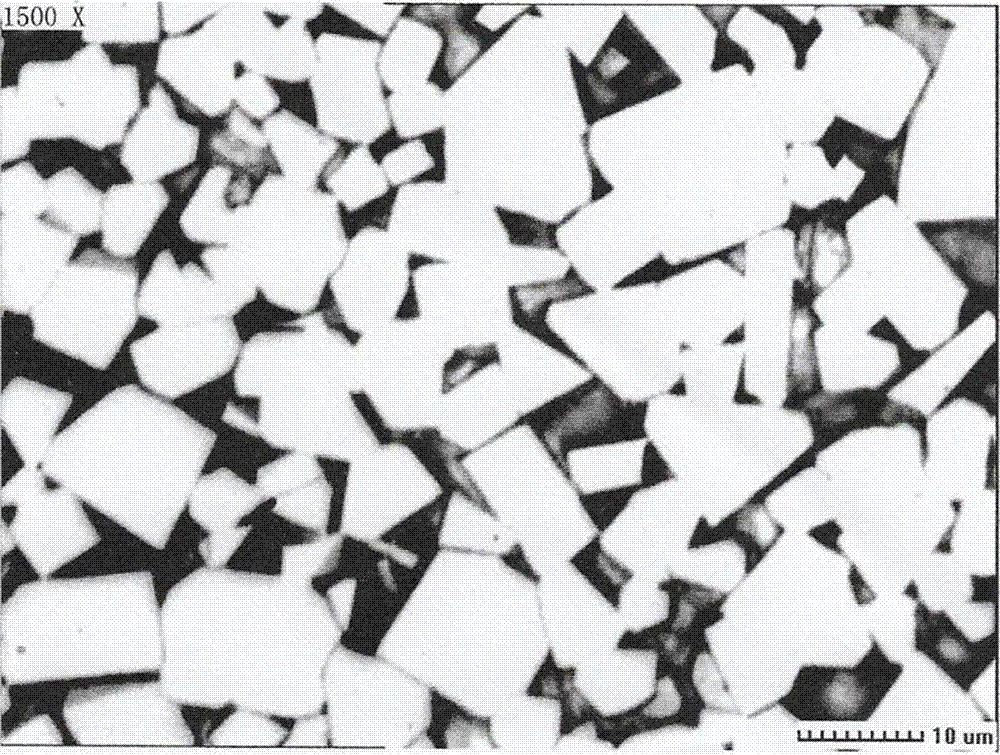

[0038] (1) Cemented carbide for vapor chamber

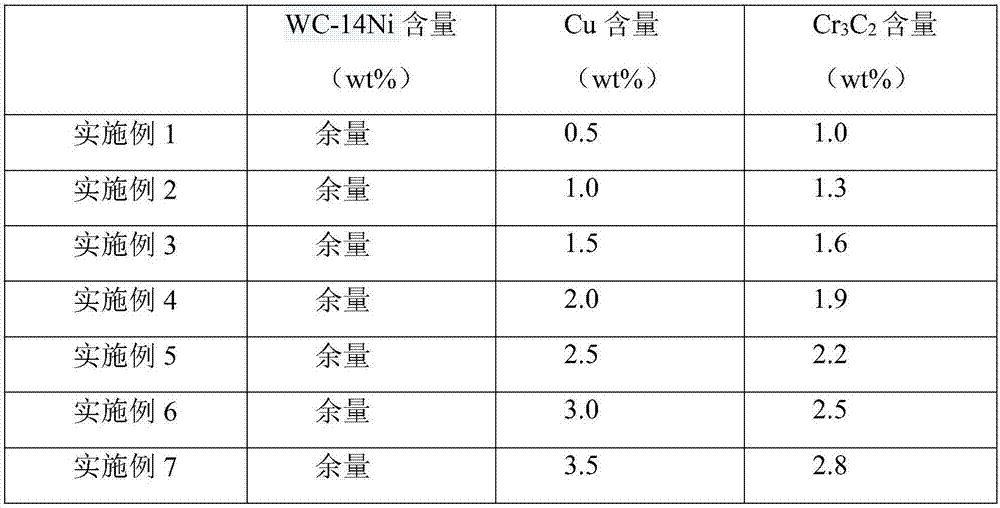

[0039] The cemented carbide for the vapor chamber of this embodiment is made by adding Cr to the ultra-coarse-grained WC-14Ni alloy 3 C 2 and Cu were prepared, wherein, each raw material was weighed according to the following mass percentages, and the specific components and contents are shown in Table 2.

[0040] (2) Preparation method of cemented carbide for vapor chamber

[0041] The preparation method of cemented carbide for vapor chamber of the present embodiment comprises the following steps:

[0042] S1. Adding Cr to ultra-coarse-grained WC-14Ni alloy 3 C 2, carry out the first wet milling, the ball-to-material ratio is 3:1, the first wet milling time is 30h, the rotating speed of the ball mill for the first wet milling is 28r / min, and the mixed material 1 is obtained;

[0043] S2. Add Cu to the mixed material 1 described in step S1. After the second wet milling, the ball-to-material ratio is 3:1. By adjusting the spe...

Embodiment 2

[0051] (1) Cemented carbide for vapor chamber

[0052] The cemented carbide for the vapor chamber of this embodiment is made by adding Cr to the ultra-coarse-grained WC-14Ni alloy 3 C 2 and Cu were prepared, wherein, each raw material was weighed according to the following mass percentages, and the specific components and contents are shown in Table 2.

[0053] (2) Preparation method of cemented carbide for vapor chamber

[0054] The preparation method of cemented carbide for vapor chamber of the present embodiment comprises the following steps:

[0055] S1. Adding Cr to ultra-coarse-grained WC-14Ni alloy 3 C 2 , carry out the first wet milling, the ball-to-material ratio is 3:1, the first wet milling time is 36h, the rotating speed of the ball mill for the first wet milling is 32r / min, and the mixed material 1 is obtained;

[0056] S2. Add Cu to the mixed material 1 described in step S1. After the second wet milling, the ball-to-material ratio is 3:1. By adjusting the sp...

Embodiment 3

[0064] (1) Cemented carbide for vapor chamber

[0065] The cemented carbide for the vapor chamber of this embodiment is made by adding Cr to the ultra-coarse-grained WC-14Ni alloy 3 C 2 and Cu were prepared, wherein, each raw material was weighed according to the following mass percentages, and the specific components and contents are shown in Table 2.

[0066] (2) Preparation method of cemented carbide for vapor chamber

[0067] The preparation method of the cemented carbide for the vapor chamber of this embodiment is the same as that of Example 1, the difference is that step S1. adding Cr to the ultra-coarse-grained WC-14Ni alloy 3 C 2 , the first wet milling was carried out, the ball-to-material ratio was 3:1, the first wet milling time was 32 hours, and the rotational speed of the ball mill for the first wet milling was 30r / min; the rest of the steps were the same as in Example 1.

[0068] (3) The method of preparing the soaking plate with cemented carbide for the soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com