Plant-based lubricating oil and application thereof

A lubricating oil, plant-based technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as high viscosity index, fast oxidation speed, heat resistance, etc., achieve low friction coefficient, low environmental pollution, and reduce useless work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

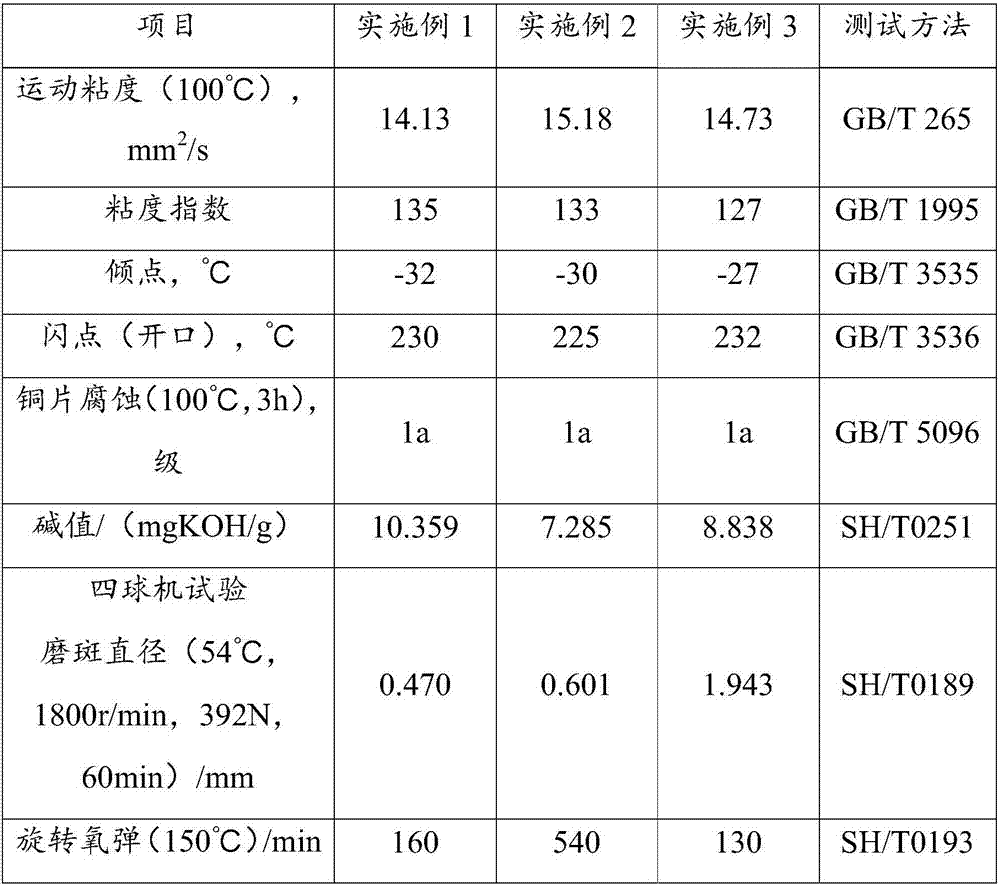

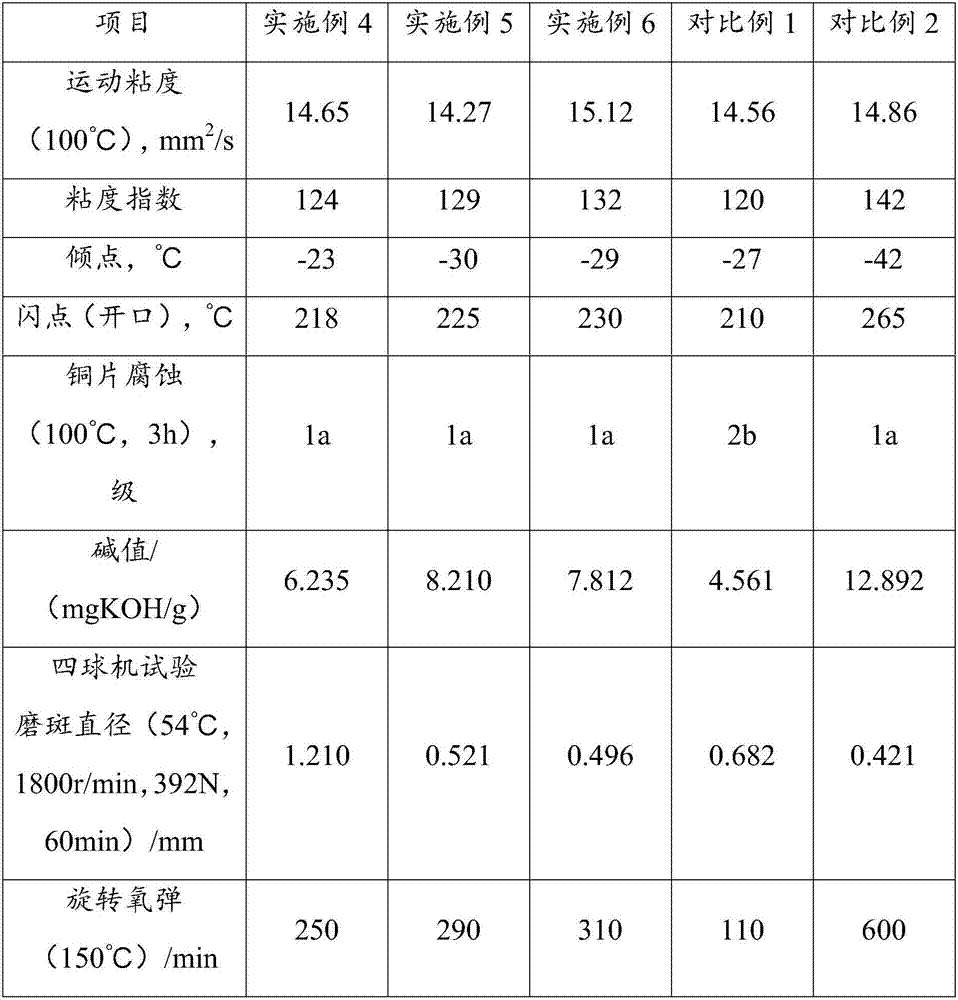

Embodiment 1

[0064] Get 59 grams of cottonseed oil, 22 grams of 100 ℃ kinematic viscosity is 18mm 2 / s GTL synthetic oil is stirred evenly at 40°C and 35rps, add 10g of VISCOPLEX 12-113 and 9g of diesel engine oil compound A, raise the temperature to 60°C, and stir at 50rps for 1h to get ready.

Embodiment 2

[0066] Take 48 grams of palm oil, 31 grams of 100 ℃ kinematic viscosity is 12mm 2 / s GTL synthetic oil is stirred evenly at 40°C and 35rps, add 9 grams of 8900E and 12 grams of diesel engine oil compound B, heat up to 60°C, stir at 50rps for 1 hour, and the product is ready.

Embodiment 3

[0068] Get 66 grams of castor oil, 18 grams of 100 ℃ kinematic viscosity is 17mm 2 / s GTL synthetic oil was stirred evenly at 40°C and 35rps, added 8 grams of SV261 and 8 grams of diesel engine oil compound C, heated to 60°C, and stirred at a speed of 50rps for 1 hour to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com