Device for detecting accelerated abrasion degradation law of linear guide rail of machine tool

A technology of linear guide rail pair and guide rail, which is applied to metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc. Reliability, small test error, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

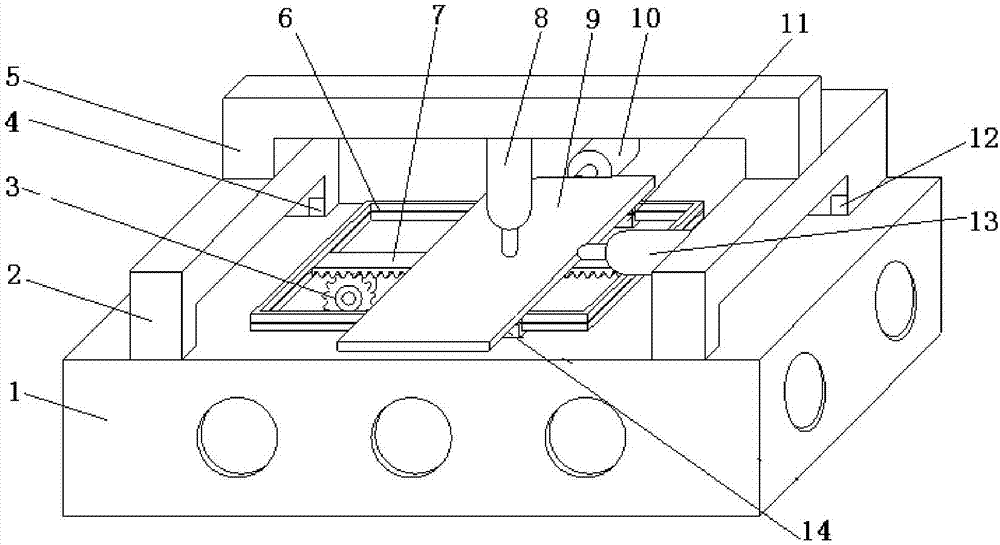

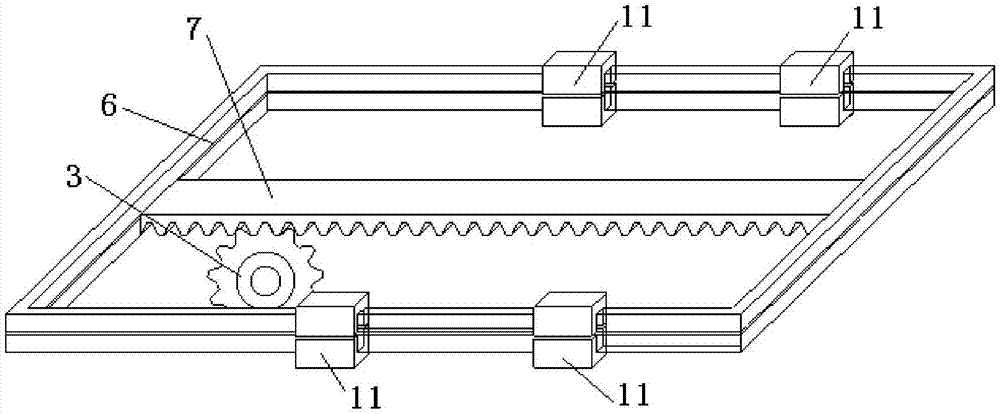

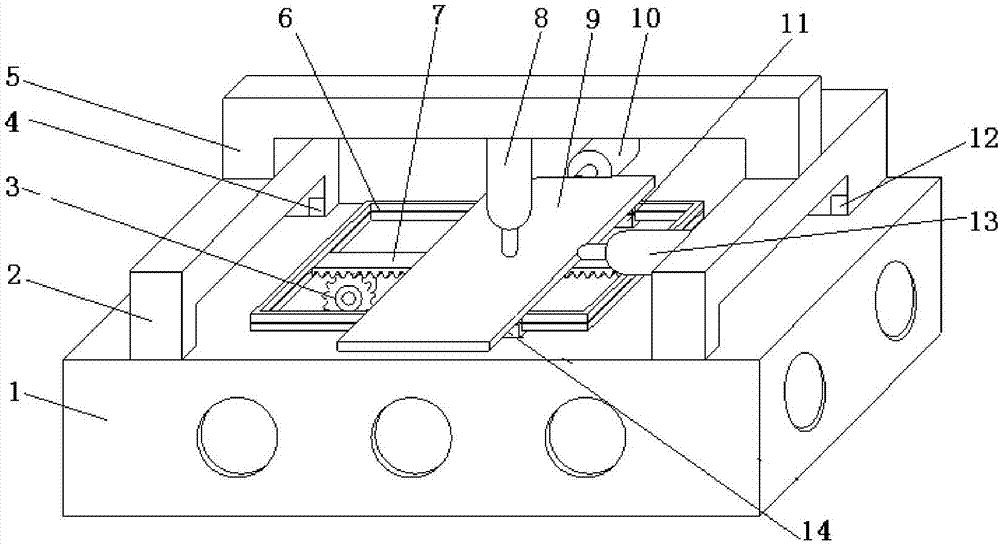

[0030] Such as Figure 1~2 As shown, the device for detecting the accelerated wear and degradation law of the linear guide rail pair of machine tools in this embodiment includes: base 1, axial loading beam 2, drive motor and gear 3, left limit switch 4, vertical loading beam 5, double-sided Slide rail 6, rack 7, vertical loading cylinder 8, working platform 9, radial loading cylinder 10, double-sided slider 11, right limit switch 12, axial loading cylinder 13, three-direction force sensor 14;

[0031] The rigidity of the base 1 is much greater than that of the linear guide pair 6 to be tested. The loading beams 2 and 5 have the ability to not deform under heavy loads. The driving motor and gear 3 adopt stepping motors or AC servo motors. The left limit switch 4 and the right The limit switches 12 are all mechanical limit switches with high sensitivity and good reliability. The rack 7 cooperates with the gear 3 to drive the double-sided guide rail 6 to reciprocate, vertically l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com