Intelligent ultrasonic crusher

A technology of ultrasonic wave and breaker, which is applied in the field of intelligent ultrasonic breaker, can solve the problems of damage to ultrasonic generating device and container, unintelligent, automatic detection, difficult automatic breaking and remote control, etc., so as to prevent damage to the container wall and improve Convenience and the effect of reducing manual misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

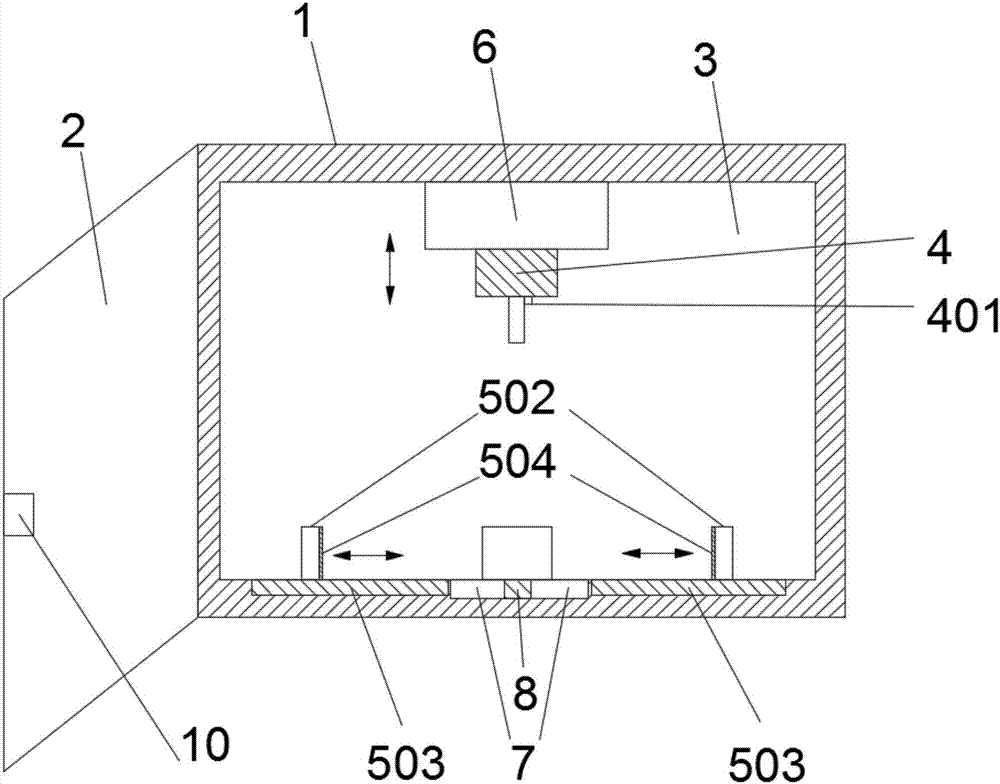

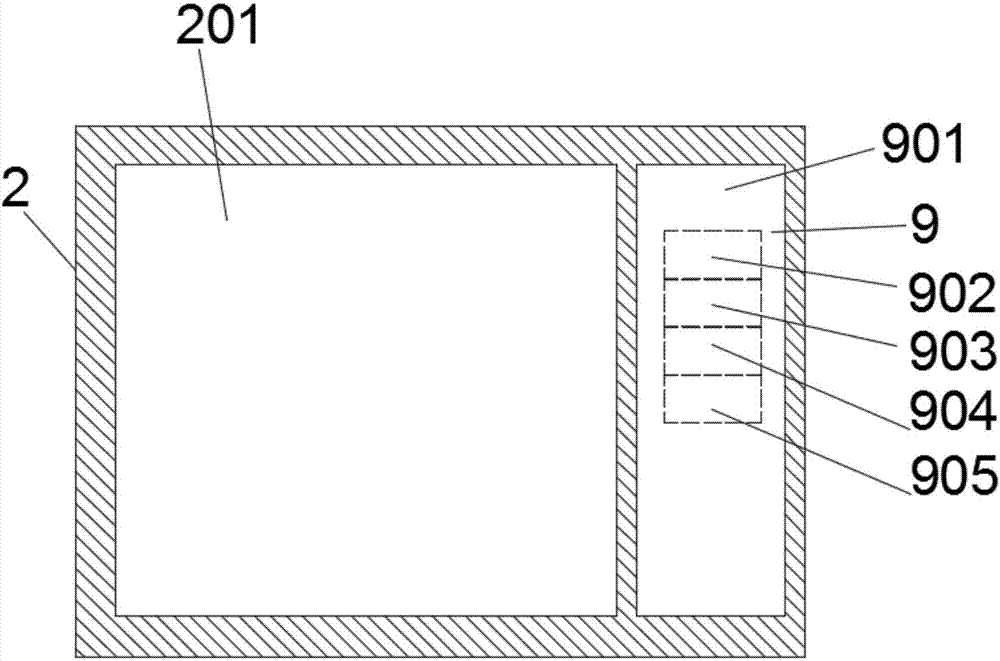

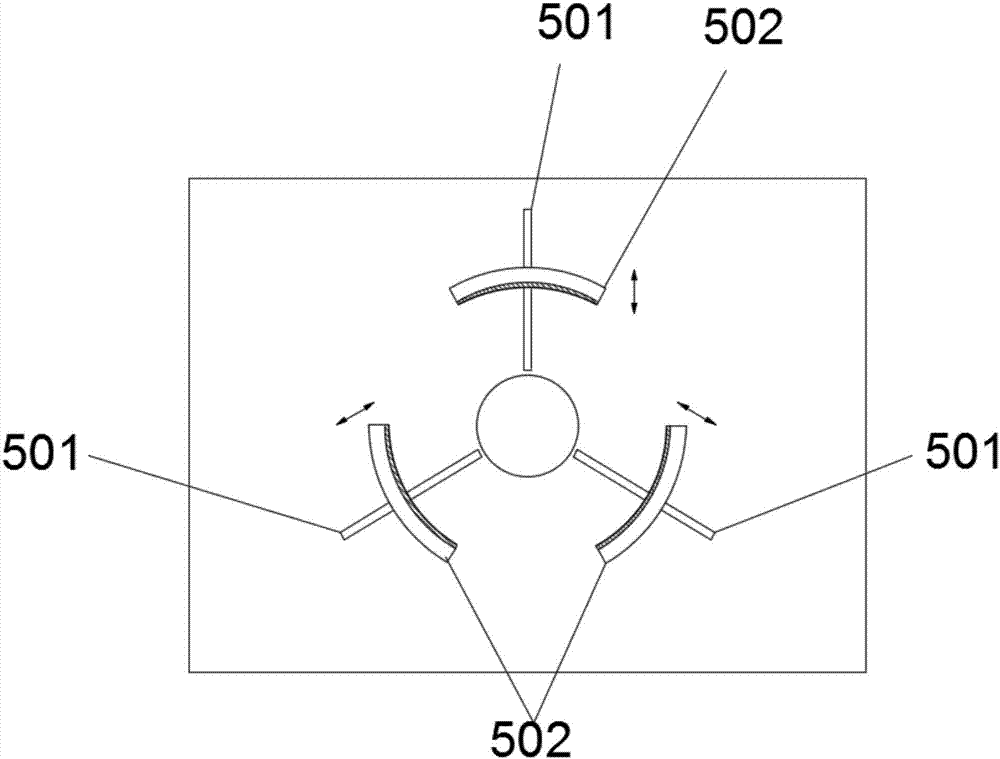

[0023] Such as Figure 1~3 As shown, an intelligent ultrasonic breaker includes a housing 1, a sealed door 2, a crushing cabin 3, and an ultrasonic probe assembly 4. The sealed door 2 is provided with an observation window 201 and a control module 9. The side of the sealed door 2 An electronic lock 10 is provided; the control module 9 includes a touch screen 901 electrically connected to each other, a microcomputer 902, a wireless communication module 903, a timing module 904, and a storage module 905; the touch screen 901 has display and touch key control functions , and also randomly display two-dimensional codes or bar codes; the center of the roof of the crushing cabin 3 is provided with a hydraulic lifting device 6, and the ultrasonic probe assembly 4 and the photoelectric sensor 401 are connected below the hydraulic lifting device 6; the ultrasonic probe assembly The bottom of the crushing chamber 3 directly below 4 is provided with a condensing device 7 and a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com