Compound bacteriostatic packaging film for meat product preservation and preparation method thereof

A meat product and packaging film technology, applied in the field of meat product preservation composite antibacterial packaging film and its preparation, can solve problems such as lack of practical applicability, achieve good meat color retention, be suitable for industrial production, improve bacteriostatic effect and fresh-keeping effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

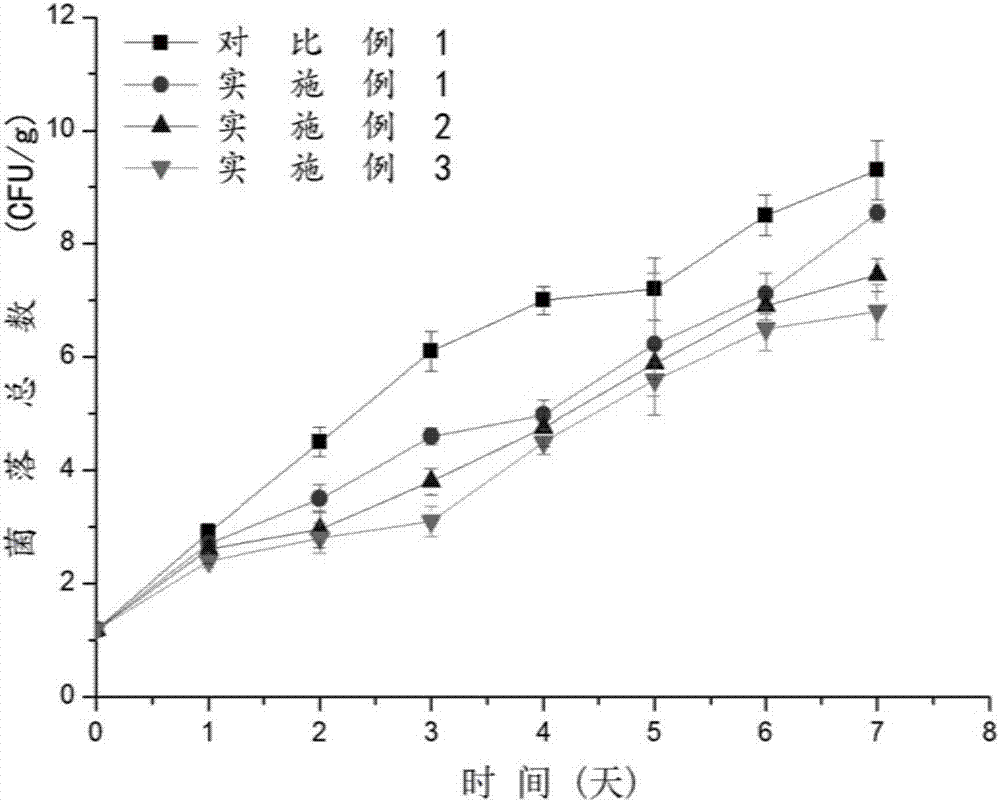

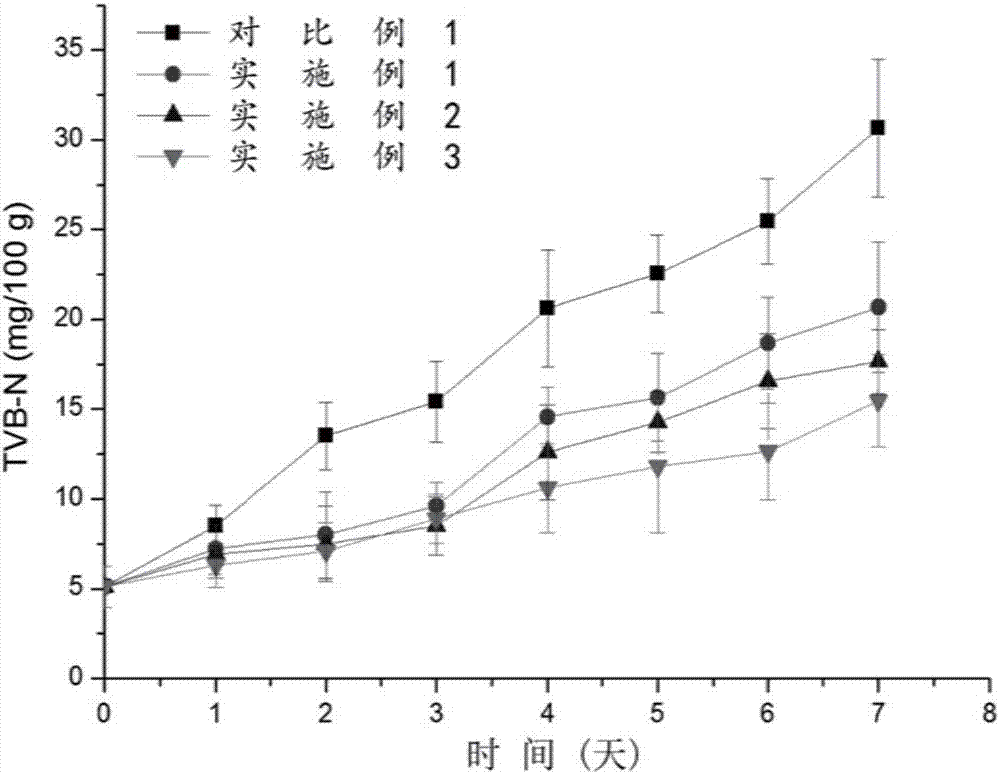

Examples

Embodiment 1

[0032] Dissolve 5g of chitosan in 100mL of 70% acetic acid solution, magnetically stir until it is completely dissolved, add 1.0g of LAE to the chitosan acetic acid solution, stir evenly, and ultrasonically remove the foam to obtain a spinning solution; The spinning device is used for spinning, and the specification of the electrospinning syringe is 2.5mL, and the needle is flat, 20G. The voltage is 15kV, the flow rate is 0.3mL / h, and the distance is 10cm. It is received by a drum, and a layer of PE film is covered on the drum receiving device. After completion, a composite electrospun nanofiber membrane is obtained.

Embodiment 2

[0034] Dissolve 5g of chitosan in 100mL of 80% acetic acid solution, magnetically stir until it is completely dissolved, add 2.5g of LAE to the chitosan acetic acid solution, stir evenly, and ultrasonically remove the foam to obtain a spinning solution; The spinning device is used for spinning, and the specification of the electrospinning syringe is 2.5mL, and the needle is flat, 20G. The voltage is 15kV, the flow rate is 0.3mL / h, and the distance is 10cm. It is received by a drum, and a layer of PE film is covered on the drum receiving device. After completion, a composite electrospun nanofiber membrane is obtained.

Embodiment 3

[0036] Dissolve 5g of chitosan in 100mL of 70% acetic acid solution, magnetically stir until completely dissolved, add 5.0g of LAE to the chitosan acetic acid solution, stir evenly, and ultrasonically remove the foam to obtain a spinning solution; The spinning device is used for spinning, and the specification of the electrospinning syringe is 2.5mL, and the needle is flat, 20G. The voltage is 15kV, the flow rate is 0.3mL / h, and the distance is 10cm. It is received by a drum, and a layer of PE film is covered on the drum receiving device. After completion, a composite electrospun nanofiber membrane is obtained.

[0037] The scanning electron microscope images of the prepared composite electrospun nanofibrous membranes are as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com