Vibratory digging harvester for winter potato

A potato and harvester technology, applied in excavating harvesters, excavators, harvesters, etc., can solve the problems of difficulty in manually digging potatoes, long harvesting time, and high labor costs, and reduce the rate of potato injury and the rate of potato injury. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below.

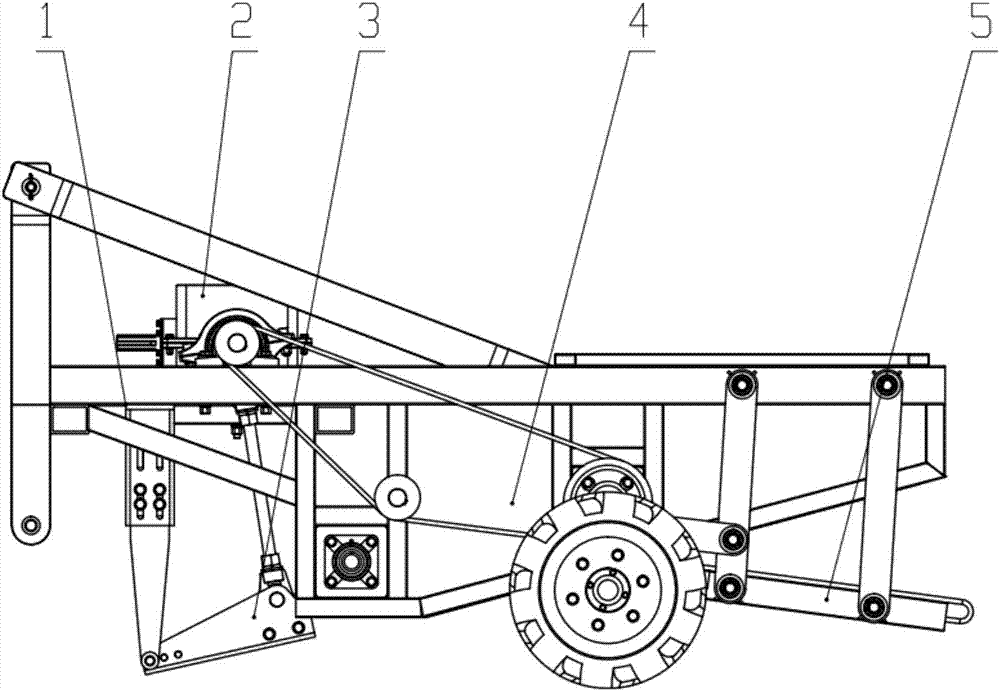

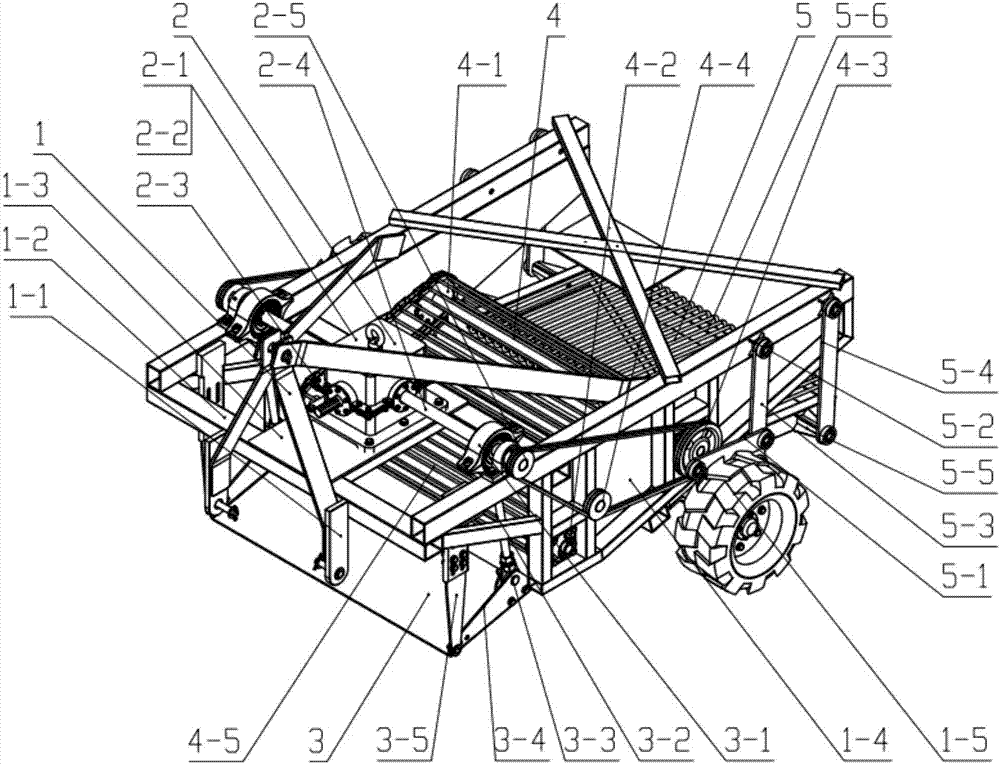

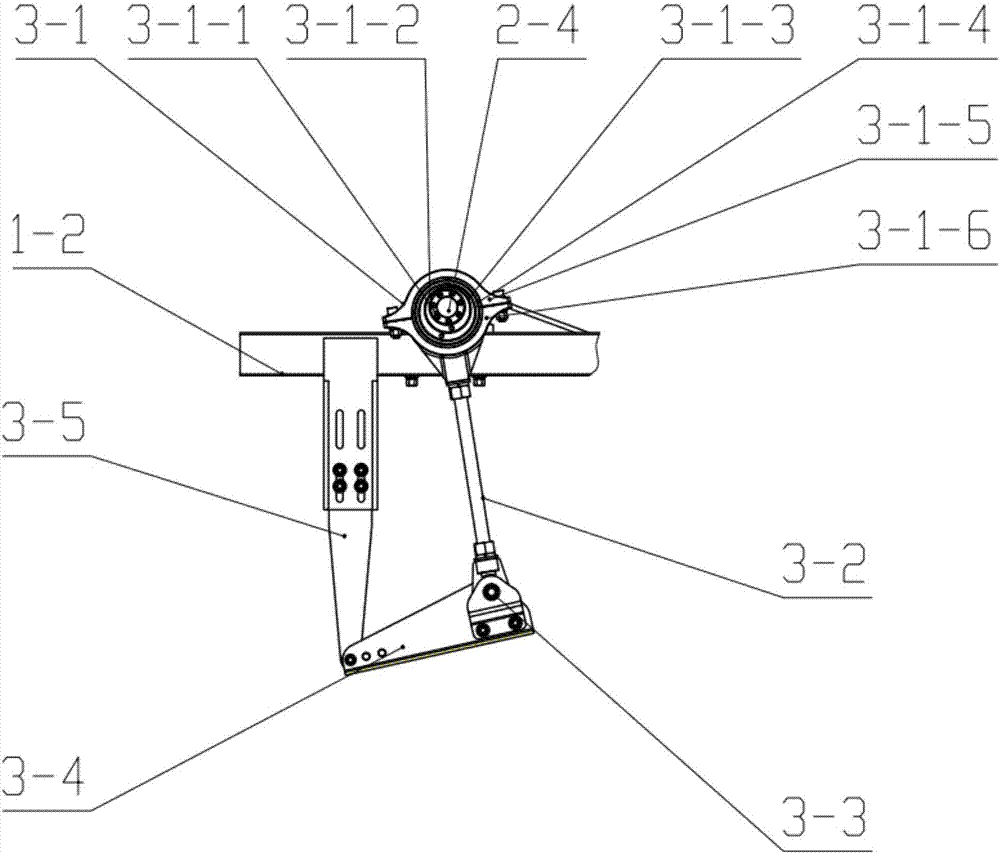

[0027] A kind of vibrating digging and harvesting machine for winter potatoes, comprising a frame 1, a gearbox 2, a vibrating digging device 3, a secondary conveying device 4 and a separation mechanism 5, such as figure 1 shown.

[0028] Gearbox 2, vibration excavation device 3, secondary conveying device 4 and separation mechanism 5 are all installed on frame 1, gearbox 2 is connected with vibration excavation device 3, secondary conveying device 4, and separation mechanism 5 is connected with secondary The conveying device 4 is mated and connected.

[0029] Each component will be described in detail below.

[0030] (1) Rack

[0031] The frame 1 includes a suspension device 1-1, a cross frame 1-2, a support frame 1-3, a baffle plate 1-4 and a ground wheel assembly 1-5. The support frame 1-3 is a steel frame mechanism with a wide front and a narrow rear, and is welded on the top of the support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com