Intelligent household mute central control machine case

A smart home and central control technology, which is applied in the screening of casings, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as rising equipment costs, loud noise, and dust entering the casing, so as to enhance system stability and reduce Noise, the effect of good electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

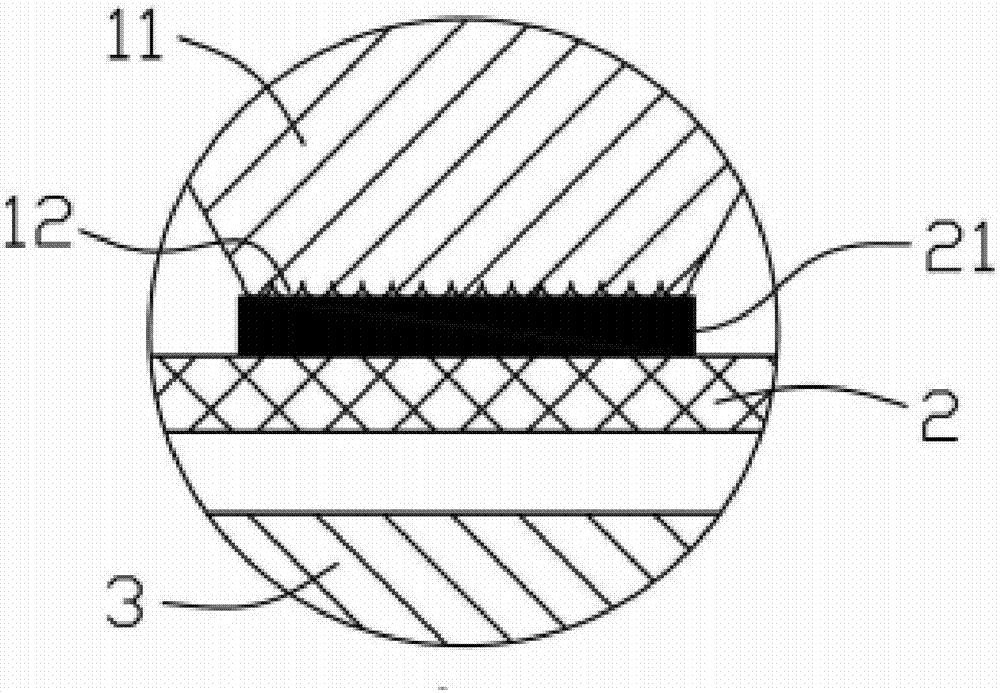

[0029] In this embodiment, the electromagnetic shielding material layer is based on a composite wave-absorbing material. The composite wave-absorbing material is based on epoxy resin, and is filled with thermally expandable graphene, carbon fiber, carbonyl iron powder, and nickel-copper ferrite composite nanomaterials. It is prepared by vacuum defoaming and stirring method, and the filler is evenly distributed in the base.

[0030] In the composite wave-absorbing material, heat-expandable graphene and carbon fiber are conductive fillers with contents of 2wt% and 7wt% respectively; carbonyl iron powder and nickel-copper ferrite composite nanomaterials are magnetic fillers with contents of 4wt% and 11wt% respectively .

[0031] The preparation steps of the composite absorbing material are as follows:

[0032] a) Preparation of thermally expandable graphene: prepare graphene oxide, then place the powdered graphene oxide in a stainless steel box, place the stainless steel box in ...

Embodiment 2

[0038] On the basis of embodiment 1, the difference is:

[0039] The carbon fiber has a length of 800 μm and a diameter of 50 μm.

Embodiment 3

[0041] On the basis of embodiment 1, the difference is:

[0042] The carbonyl iron powder was spherical with a particle diameter of 40 μm.

[0043] Preferably, the following table shows the reflection loss of the composite absorbing material obtained in the above embodiment in the 2-20 GHz frequency band:

[0044]

[0045] It can be seen from the above table that compared with Example 2 and Example 3, in the case of changing the size of carbon fiber and carbonyl iron powder, the wave-absorbing performance of the composite wave-absorbing material drops seriously. In Example 1, the composite wave-absorbing material The wave material has good wave-absorbing performance for electromagnetic waves in the 2-20GHz frequency band, with a maximum absorption of 33.6dB, and the consistency of wave absorption in this frequency band is good, with an average absorption of 29.8dB, which has achieved unexpected results. The performance of the multi-component composite absorbing mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com