Mode aberration correction device for confocal microscope

A confocal microscope and aberration technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inconvenient operation, complicated sample pretreatment steps, and complicated aberration correction devices, etc., to achieve simplified devices, Imaging quality improvement, imaging amplitude enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

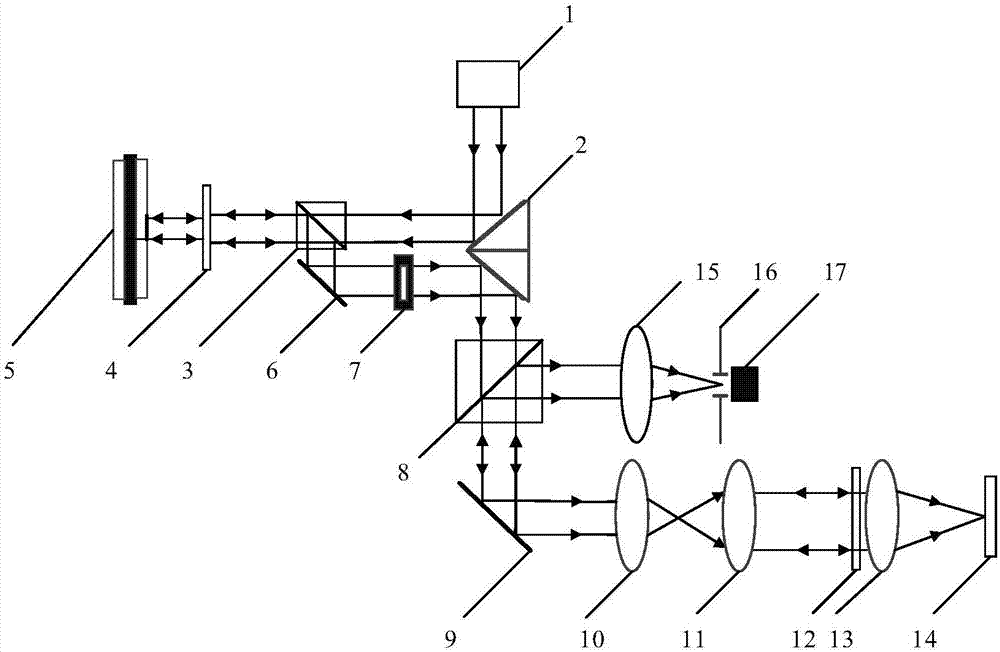

[0016] like figure 1 As shown, the confocal microscope mode aberration correction device of the present invention includes a laser 1, a double-sided 45° mirror 2, a beam splitter 3, a half-wave plate 4, a spatial light modulator 5, a mirror 6, a diaphragm 7. Polarizing beam splitter 8, XY scanning galvanometer 9, scanning lens 10, tube mirror 11, objective lens 12, 1 / 4 wave plate 13, collecting lens 15, fiber hole 16 and photomultiplier tube 17;

[0017] The laser light emitted by the laser 1 is reflected by the mirror surface of one side of the double-sided 45° mirror 2 and then reaches the half-wave plate 4 through the beam splitter 3 , and is modulated by the half-wave plate 4 and then injected into the spatial light modulator 5 . After being modulated by the spatial light modulator 5, it is sent back to the beam splitter 3, and then reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com