Accessory milling head speed-increasing gearbox

A speed-increasing gearbox and milling head technology, which is applied to transmission parts, metal processing machinery parts, gear transmissions, etc., can solve problems such as insufficient speed and waste of resources, and achieve smooth speed-up, increase utilization rate, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

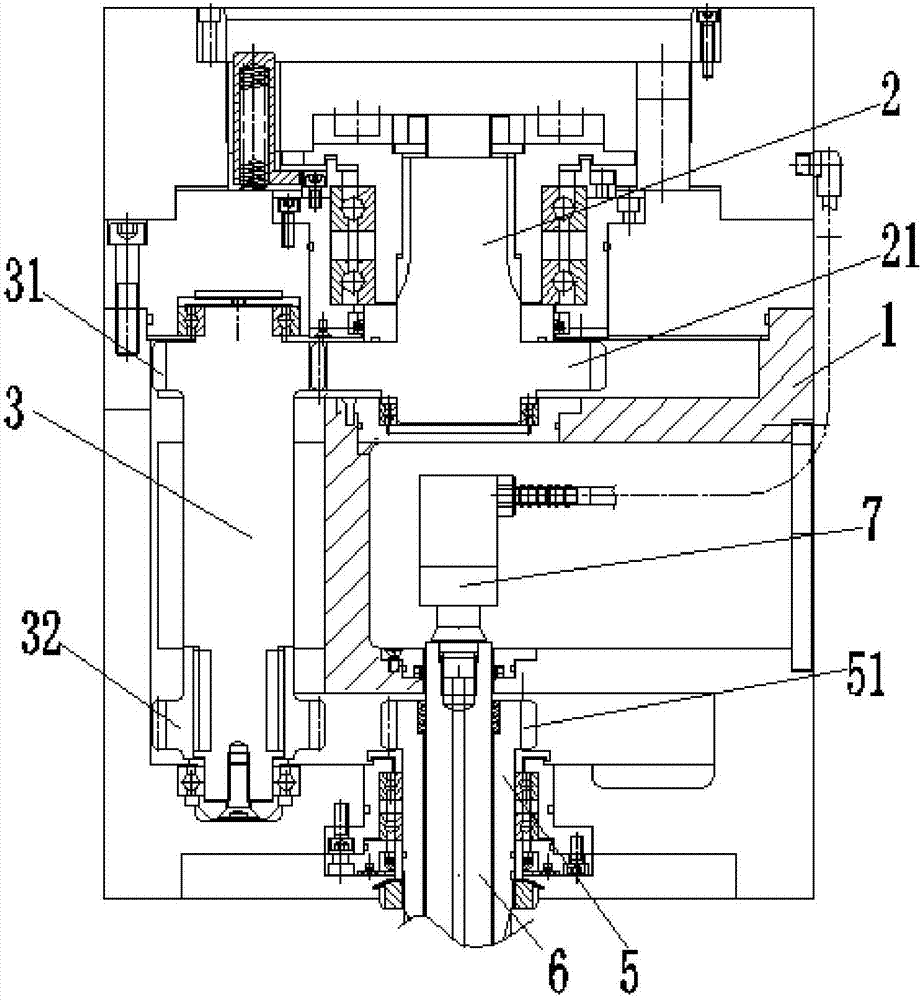

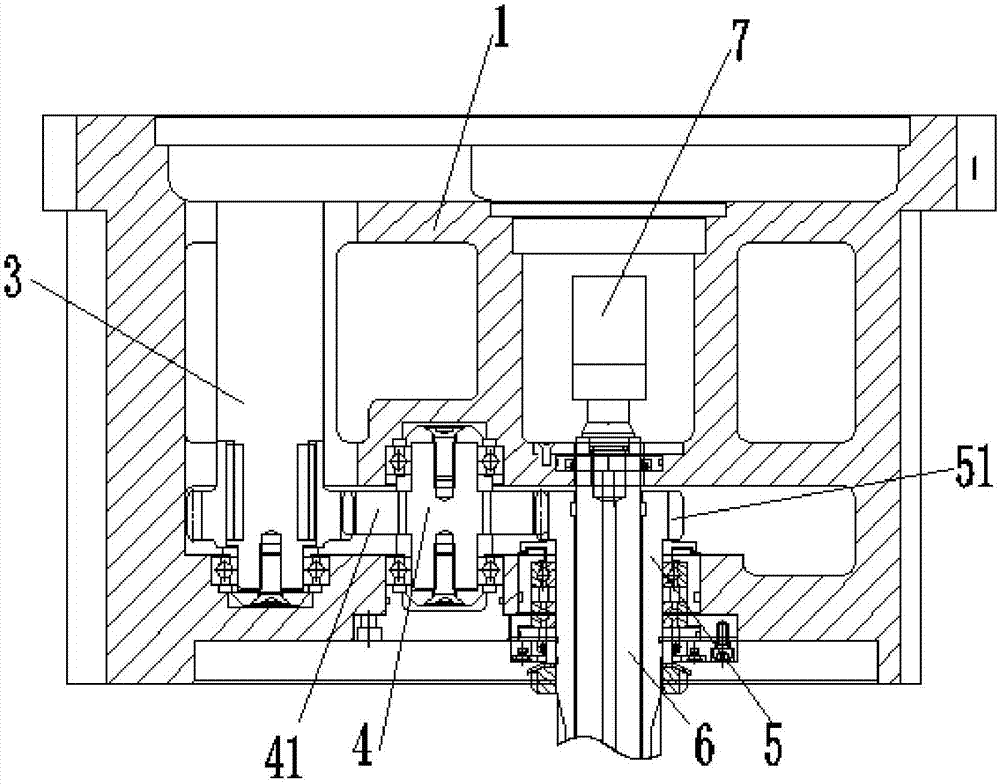

[0014] see figure 1 , 2 As shown, an accessory milling head gearbox, including a box body 1, an input gear shaft 2, an intermediate gear shaft 3, a spline shaft 4, an output gear shaft 5 and a transition shaft 6, the input gear shaft 2, the intermediate gear shaft The shaft 3, the spline shaft 4 and the output gear shaft 5 are all rotationally connected with the box body 1 through deep groove ball bearings, so that the rotation effect is good and stable mechanical transmission is realized.

[0015] see figure 1 As shown, the end of the input pinion shaft 2 is provided with an integrated first gear 21, and one end of the intermediate gear shaft 3 is provided with an integrated second gear 31, and the first gear 21 and the second gear Two gears 31 are meshed for transmission. The number of teeth of the first gear 21 and the second gear 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com