Rail beam dust-removing deicing vehicle and suspended type monorail transportation system

A technology for monorail traffic and deicing vehicles, applied in the field of rail traffic, can solve problems such as brake failure and wheel slippage, and achieve the effect of reducing wheel slippage and improving driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

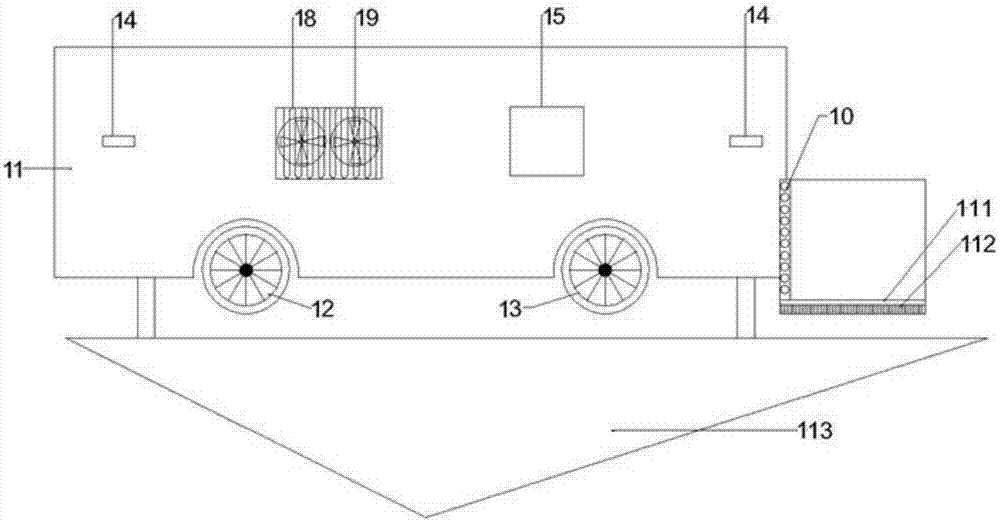

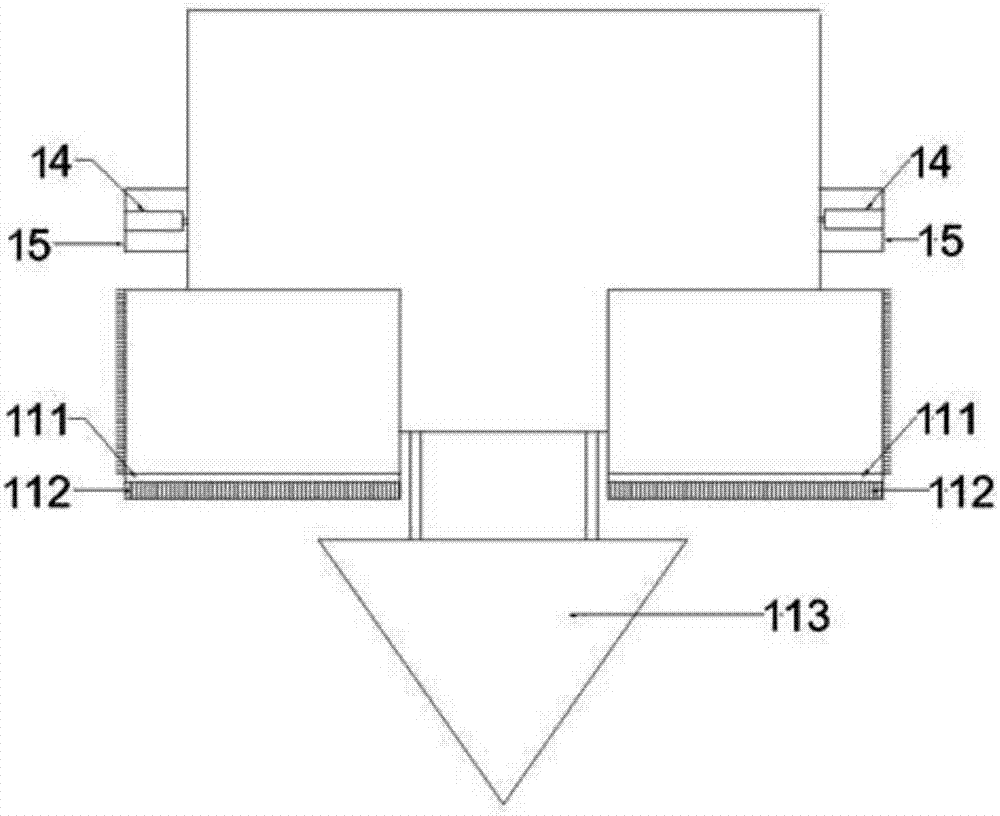

[0072] A track beam dust removal and deicing vehicle, comprising a car body 11, a dust removal and deicing mechanism for removing thin ice and dust is arranged on the car body 11, and the dust removal and deicing mechanism includes an ice-breaking component, an ice-rolling component and a dust-cleaning and ice-cleaning mechanism The ice breaking component is mainly used to turn the ice layer into a water film, the ice grinding component is mainly used to break the ice layer, and the dust and ice cleaning component is mainly used to clean the cracked ice layer and carbon brush powder out of the track beam. The ice-breaking assembly, the ice-milling assembly and the dust-cleaning and ice-sweeping assembly are installed on the car body 1 along the direction in which the car body 11 travels.

Embodiment 2

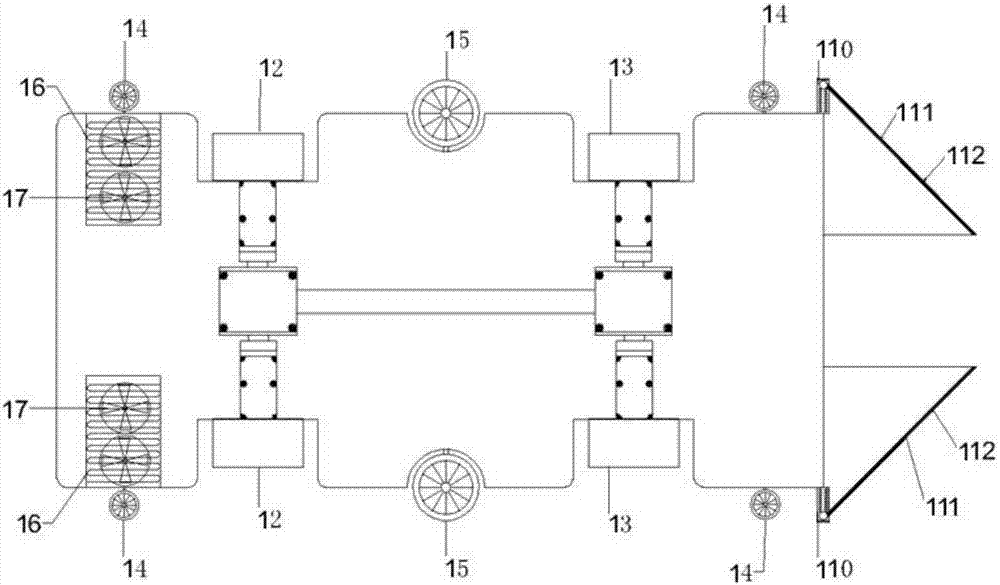

[0074] On the basis of the first embodiment, the ice-breaking assembly includes a walking rail surface ice-breaking assembly and a guide rail surface ice-breaking assembly. There are at least two groups of ice-breaking components on the running rail surface, and multiple groups of ice-breaking components on the running rail surface are arranged on the left and right sides of the front end of the bottom surface of the car body 11 . as attached figure 1 As shown, there are four groups of ice-breaking components on the running rail surface, and the four groups of ice-breaking components on the running rail surface are in pairs. The surface ice-breaking assemblies are arranged side by side on the right side of the front end of the bottom surface of the car body 11 . The ice breaking assembly on the running rail surface includes a first fan 17 and a first electric heater 16 , the first fan 17 is fixedly connected to the bottom surface of the vehicle body 11 , and the first electri...

Embodiment 3

[0076] On the basis of Embodiment 1 or Embodiment 2, the ice rolling assembly includes a walking rail surface ice rolling assembly and a guide rail surface ice rolling assembly. The ice-milling assembly on the running rail is set corresponding to the ice-breaking assembly on the running rail, and the ice-milling assembly on the running rail is placed behind the ice-breaking assembly on the running rail. This walking track surface ice grinding assembly comprises front traveling wheel 12, rear traveling wheel 13, and front traveling wheel 12, rear traveling wheel 13 are installed on the car body 11 one after the other. The ice-milling assembly on the guide rail surface is arranged corresponding to the ice-breaking assembly on the guide rail surface, and the ice-milling assembly on the guide rail surface is placed behind the ice-breaking assembly on the guide rail surface. The ice rolling assembly on the guide rail surface includes rolling wheels 15, and rolling wheels 16 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com