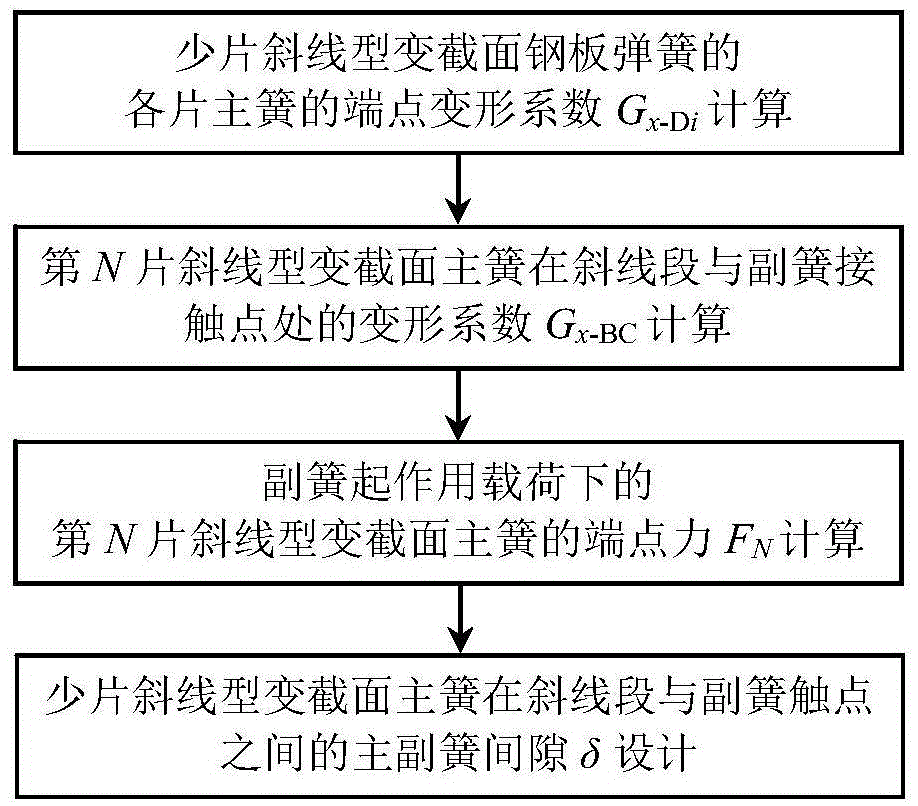

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

A design method, a slash-type technology, applied in the field of vehicle suspension leaf springs, can solve problems such as inability to provide analytical design formulas, failure to meet design requirements, and not given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

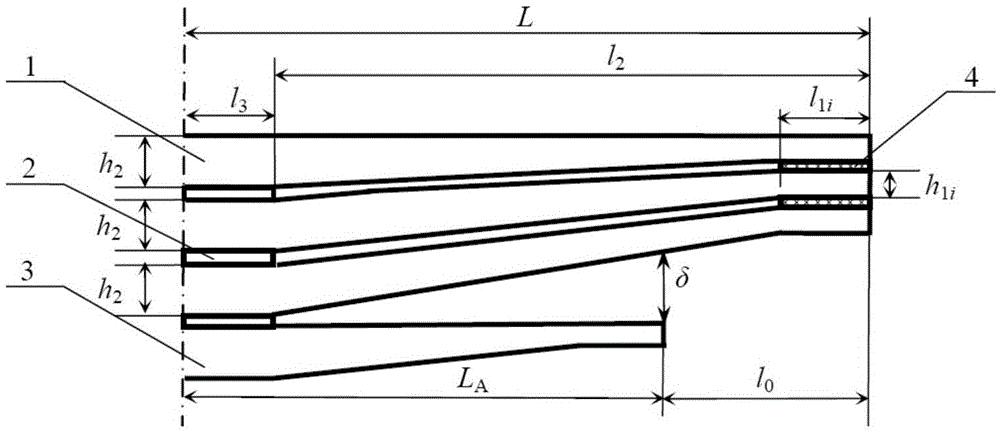

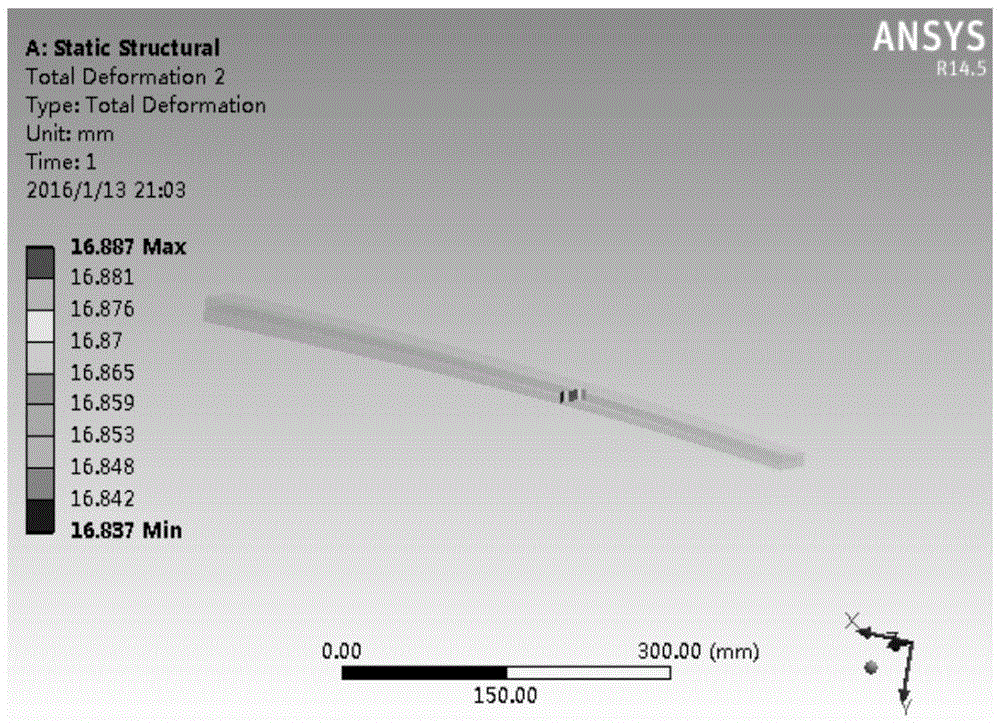

[0033] Embodiment 1: The number of sheets of a certain oblique line type variable cross-section main spring is N=2, wherein, half of the length of each main spring is L=575mm, width b=60mm, modulus of elasticity E=200GPa, root thickness h 2 =11mm, half of the installation distance l 3 =55mm, the distance l from the root of the oblique line to the end of the main spring 2 =L-l 3 =520mm; Thickness h of the straight section at the end of the first main spring 11 =7mm, that is, the thickness ratio β of the oblique line section of the first main spring 1 = h 11 / h 2 =0.64; the thickness h of the straight section at the end of the second main spring 12 =6mm, that is, the thickness ratio β of the oblique line section of the second main spring 2 = h 12 / h 2 =0.55; half length L of secondary spring A =355mm, the horizontal distance from the secondary spring contact point to the main spring end point l 0 =L-L A =220mm, the auxiliary spring contact is in contact with a certain...

Embodiment 2

[0053] Embodiment 2: The number of sheets of a certain oblique line type variable cross-section main spring is N=2, wherein, half of the length of each main spring is L=600mm, width b=60mm, modulus of elasticity E=200GPa, straight section at the root Thickness h 2 =14mm, half of the installation distance l 3 =60mm, the distance l from the root of the oblique line to the end of the main spring 2 =L-l 3 =540mm; Thickness h of the straight section at the end of the first main spring 11 =9mm, that is, the thickness ratio β of the oblique line section of the first main spring 1 = h 11 / h 2 =0.64; the thickness h of the straight section at the end of the second main spring 12 =8mm, that is, the thickness ratio β of the oblique line section of the second main spring 2 = h 12 / h 2 =0.57; half length L of secondary spring A =340mm, the horizontal distance l between the auxiliary spring contact and the main spring end point 0 =L-L A =260mm, the auxiliary spring contact is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com