A kind of method of producing propionibacterium bacteriocin by high-density fermentation

A technology of high-density fermentation and propionibacterium, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of relatively little research on nitrogen sources, and achieve the advantages of convenient transportation, industrial production, and increased production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of indicator bacteria: Inoculate the activated E. coli into LB liquid medium, culture at 37°C and shake at 220r / min until the OD of the bacterial solution 600nm 0.2, and then diluted 100 times with sterile LB medium for use.

[0032] Preparation of distiller's grain supernatant: Distiller's grains were stirred at 30°C for 3 hours according to the mass ratio of distiller's grains to distilled water of 1:4, centrifuged in a centrifuge at 4200r / min for 5min and filtered to obtain distiller's grain filtrate.

[0033] Configuration of yeast solution: Dissolve 2g of yeast powder in 1000mL of distilled water to make 2g / L yeast solution.

[0034] The following examples carry out the mensuration of antibacterial activity according to the following method: fermented liquid is centrifuged 15min under the condition of 4 ℃, 6000r / min, gets supernatant, is adjusted to pH7.0 with 10% NaOH, then with 10% tartaric acid Adjust the pH to 5.5, and then perform ultrafiltration ...

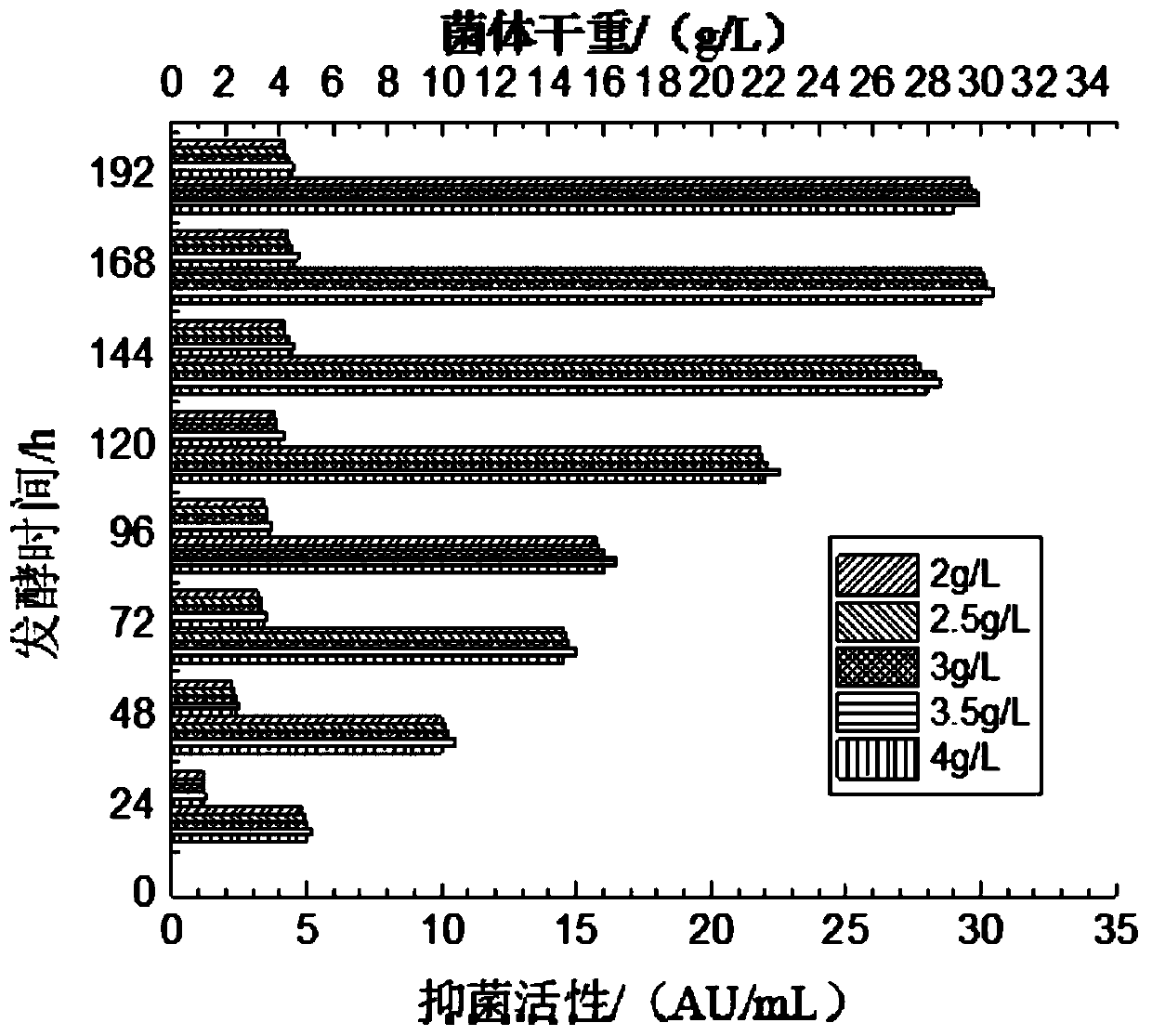

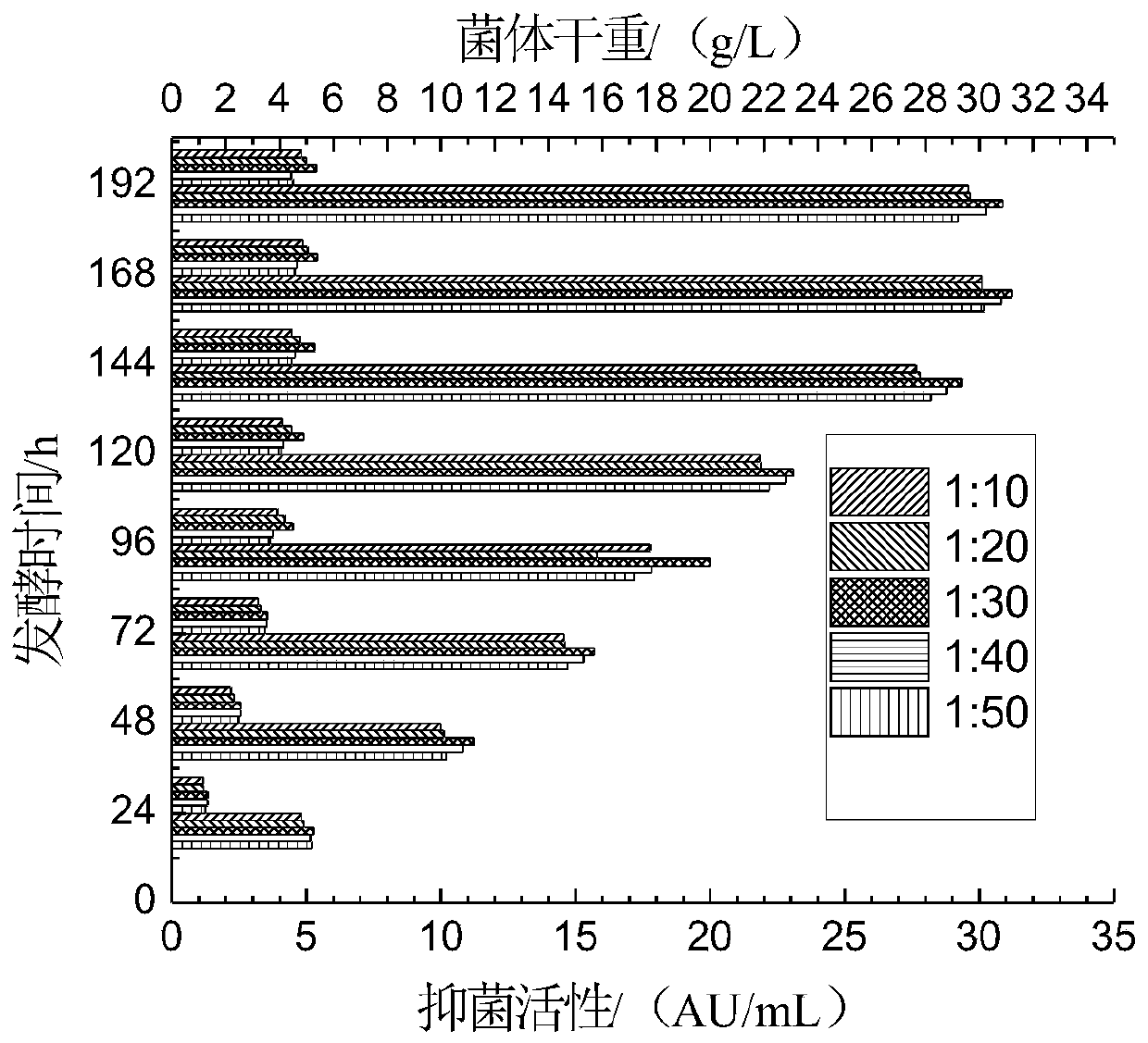

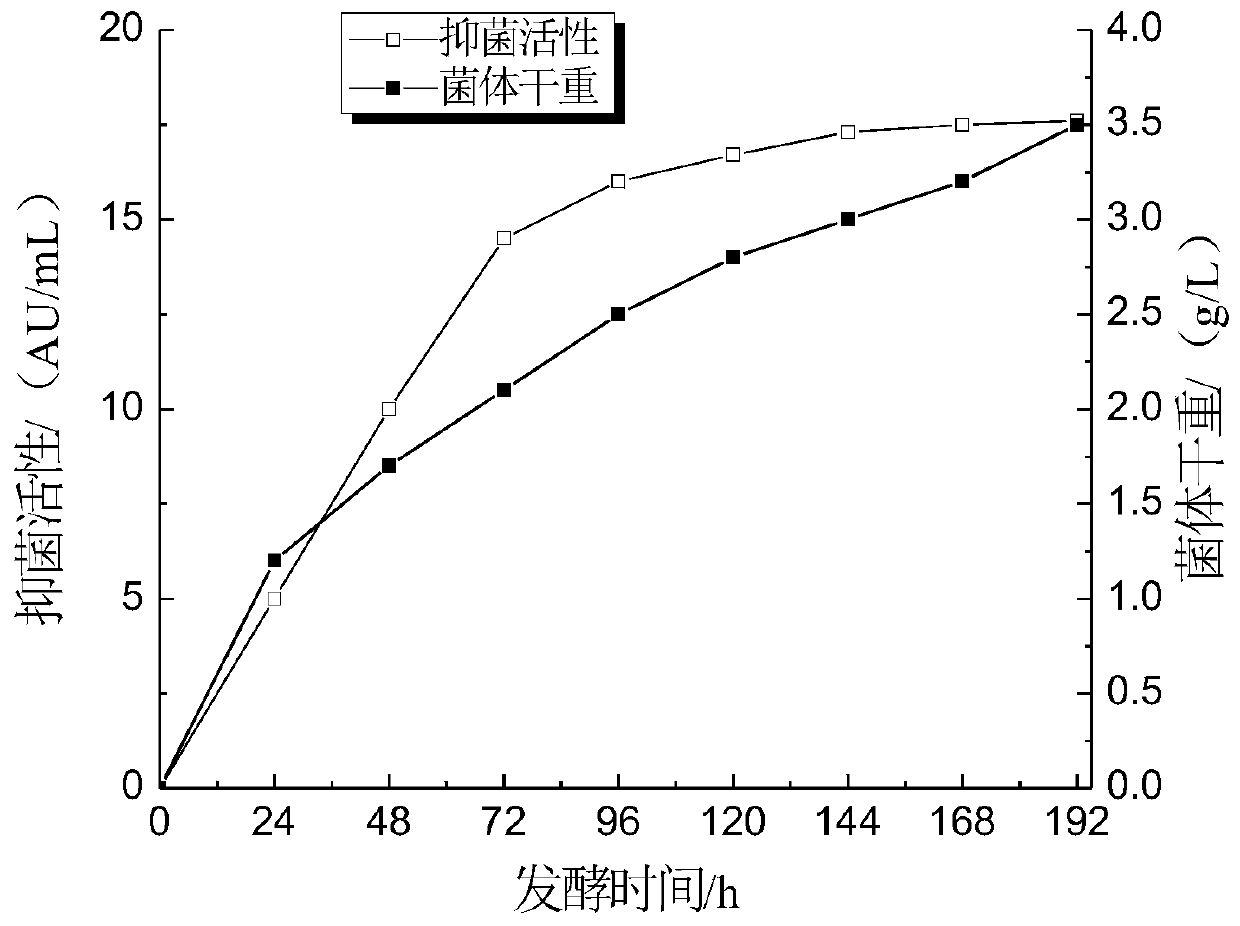

Embodiment 1

[0036] 1. Seed culture: inoculate a single colony of Propionibacterium freudenreichii CS1420 into a modified PYG medium for activation, and culture anaerobically at 30°C for 2.5 days. Improved PYG medium formula: casein peptone 5.0g, peptone 5.0g, yeast extract 10.0g, beef extract 5.0g, glucose 5.0g, K2HPO4 2.0g, Tween 80 1.0ml, resazurin 1.0ml, saline solution ( Recipe attached below) 40.0ml, distilled water 950.0ml, hemin solution (recipe attached below) 10.0ml, vitamin K1 solution (recipe attached below) 0.2ml, L-cysteine 0.5g, pH 7.2. Salt solution: CaCl 2 2H 2 O 0.25g, MgSO 4 ·7H 2 O 0.5g, K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, NaHCO 3 10.0g, NaCl 2.0g, distilled water 1.0L. Hemin solution: 50.0 mg of hemin, 1.0 ml of 1N NaOH, and 99.0 ml of distilled water. Vitamin K1 solution: vitamin K10.1ml, 95% ethanol 20.0ml.

[0037] 2. Expanded cultivation: transfer the seed solution obtained in the above step 1 into a Erlenmeyer flask equipped with SLB medium according t...

Embodiment 2

[0041] Same as Example 1, the difference is that the added concentration of carbon source is 2.5g / L.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap