Adhesive for reflective material for clothing and its preparation method, application, and use method

A technology of reflective materials and adhesives, applied in the direction of adhesive types, modified epoxy resin adhesives, polyurea/polyurethane adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

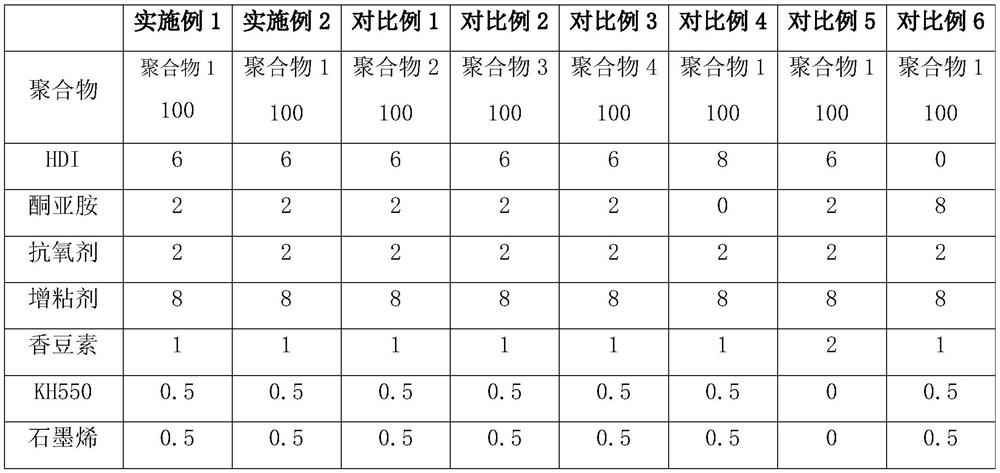

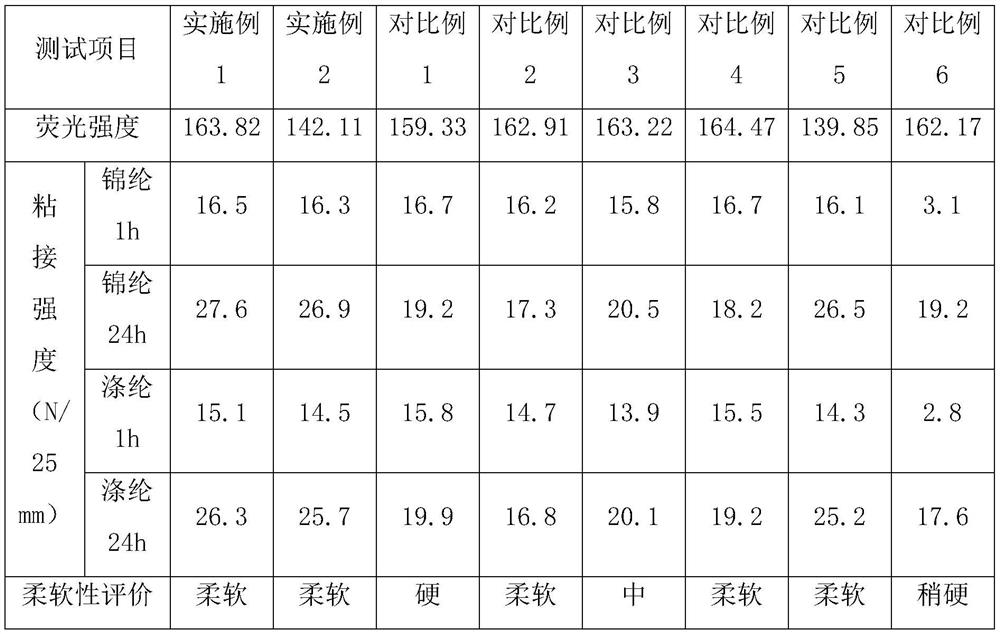

Examples

preparation example Construction

[0048] A preparation method for preparing a reflective material adhesive for clothing, comprising the following preparation steps:

[0049](1) Preparation of fluorescent components

[0050] Mix the silane coupling agent, graphene and organic fluorescent agent evenly to obtain the fluorescent component;

[0051] (2) Preparation of flexible acrylic polymer

[0052] Polyurethane acrylate, 2-ethylhexyl acrylate, epoxy acrylate, and hydroxyethyl acrylate are free radically polymerized to obtain flexible acrylic polymers;

[0053] (3) Preparation of adhesive

[0054] Mix the flexible acrylic polymer and fluorescent components evenly, add hexamethylene diisocyanate, and react under stirring conditions for more than 1 hour; then add antioxidant, tackifier, ketimine and fluorescent components and stir evenly.

[0055] The pre-mixing of the fluorescent components in step (1) is to enable the organic fluorescent agent to be more efficiently loaded on the surface of the graphene, and t...

preparation example 1

[0065] 35 parts by weight of polyurethane acrylate, 25 parts by weight of 2-ethylhexyl acrylate, 4 parts by weight of epoxy acrylate, and 6 parts by weight of hydroxyethyl acrylate are used to initiate free radical polymerization through an initiator to obtain a polymerization with a molecular weight of about 350,000. Object 1.

preparation example 2

[0067] 60 parts by weight of 2-ethylhexyl acrylate, 4 parts by weight of epoxy acrylate, and 6 parts by weight of hydroxyethyl acrylate were initiated by an initiator for radical polymerization to obtain polymer 2 with a molecular weight of about 350,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com